Electricity auxiliary heater and production method thereof

An electric auxiliary heater and heating tube technology, which is applied in the field of sheet metal forming, can solve problems such as low welding efficiency, low pass rate, and high product failure rate, and achieve beautiful welding effects, stable welding quality, and high assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

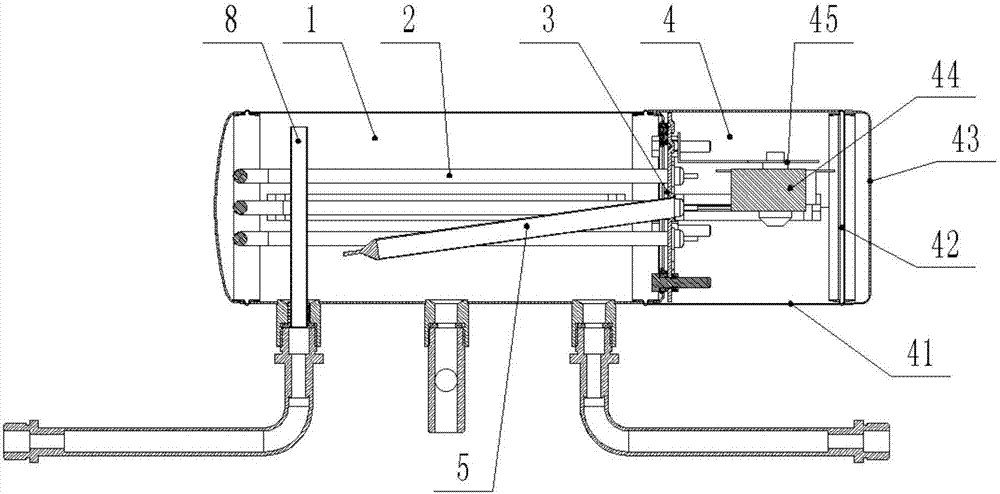

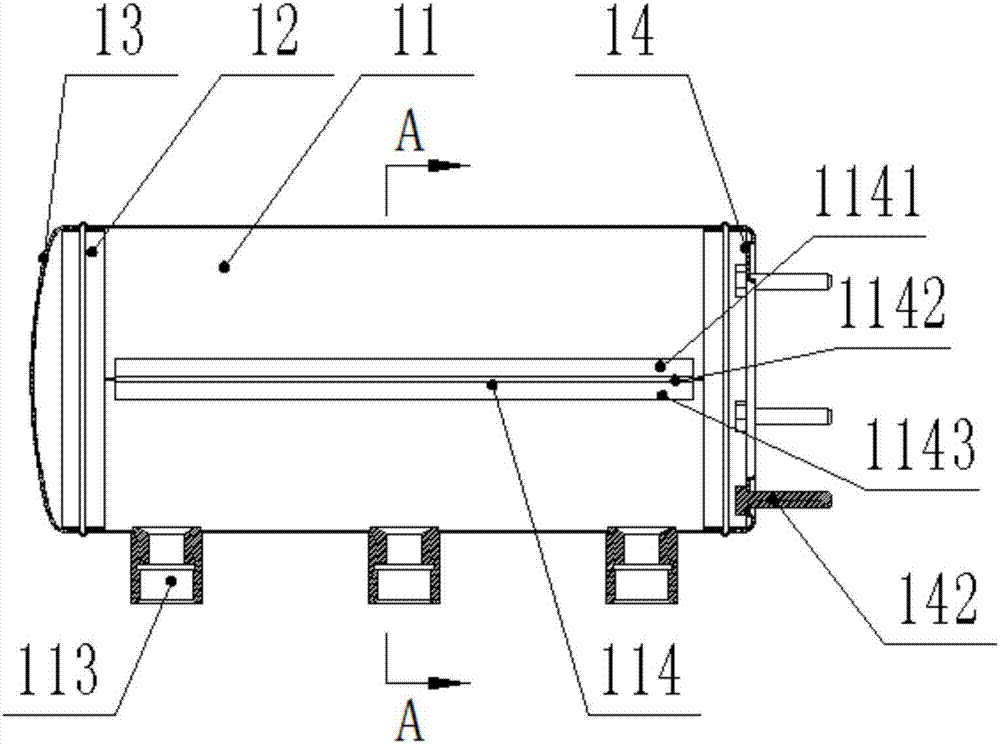

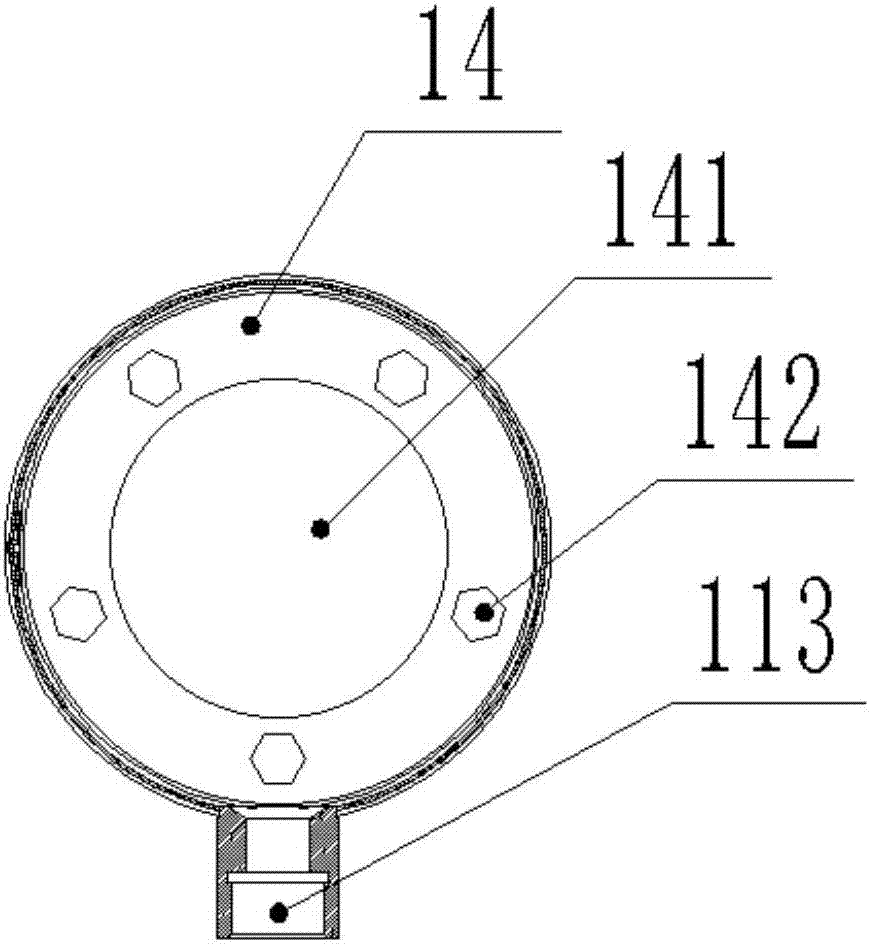

[0061] like Figure 1-7 As shown, the electric auxiliary heater includes a water chamber 1 for storing water, a heating pipe 2 extending into the water chamber 1 and heating the water in the water chamber 1, and the water chamber 1 includes a water chamber straight barrel 11. Two water cavity transition connecting rings 12, a first water cavity side head 13 and a water cavity second side head 14, the water cavity straight barrel 11 is a barrel with a cylindrical hollow cavity, the water cavity The cavity transition connecting ring 12 is provided with a first annular boss 122, and both sides of the first annular boss 122 are provided with a water cavity first lap ring 121 and a water cavity second lap ring 123, the water cavity is directly Both ends of the body barrel 11 are respectively connected with the corresponding second lap rings 123 of the water cavity by spot welding and are sealed by brazing, and the first lap rings 121 of the water cavity are respectively connected w...

Embodiment 2

[0105] The structures of the second embodiment and the first embodiment are basically the same, and the similarities will not be repeated, and their differences will be described below.

[0106] like Figure 8 As shown, the electric auxiliary heater of the second embodiment lacks the control cavity 4, and adds a casing 6 arranged on the circumference of the water cavity 1,

[0107] The casing 6 includes a casing straight barrel 61, a casing transition connecting ring 62, a casing head 63 and a casing end cover 64. The casing straight barrel 61 is a barrel with a cylindrical hollow cavity, and the casing transition connecting ring 62 is provided with a third annular boss, the two sides of the third annular boss are provided with the first lap ring of the casing and the second lap ring of the casing, and one end of the casing straight barrel 61 is connected to the corresponding second casing of the casing. The lap rings are connected by spot welding and sealed by brazing. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com