Sewage treatment system

A sewage treatment system and water inflow technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. And the problem of unstable phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

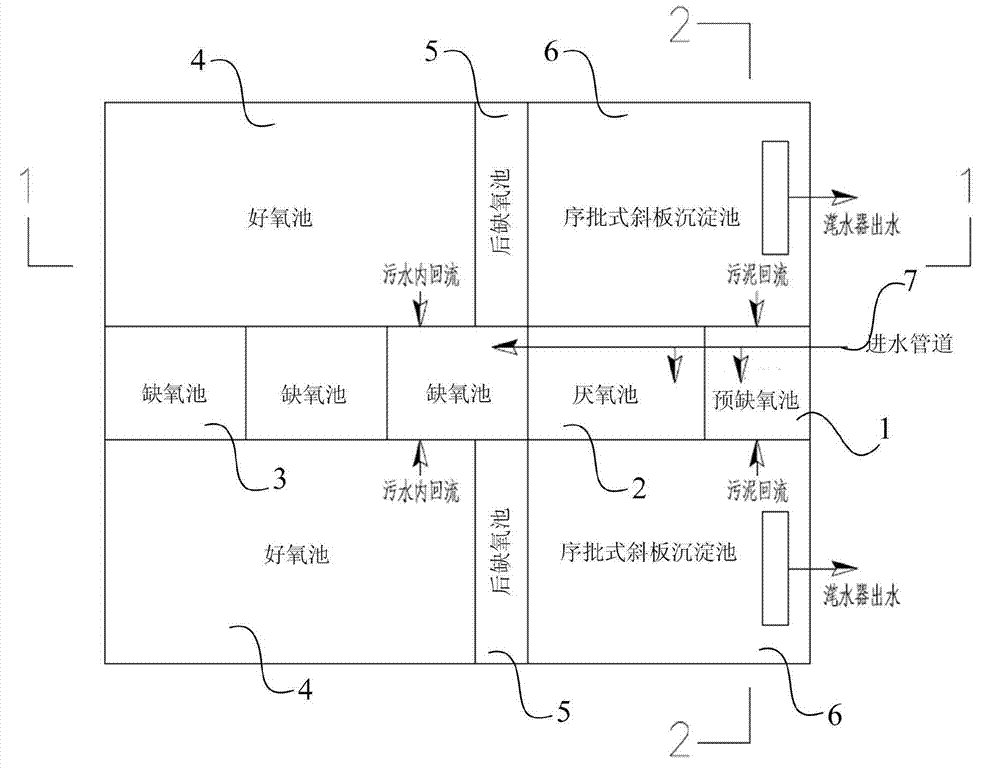

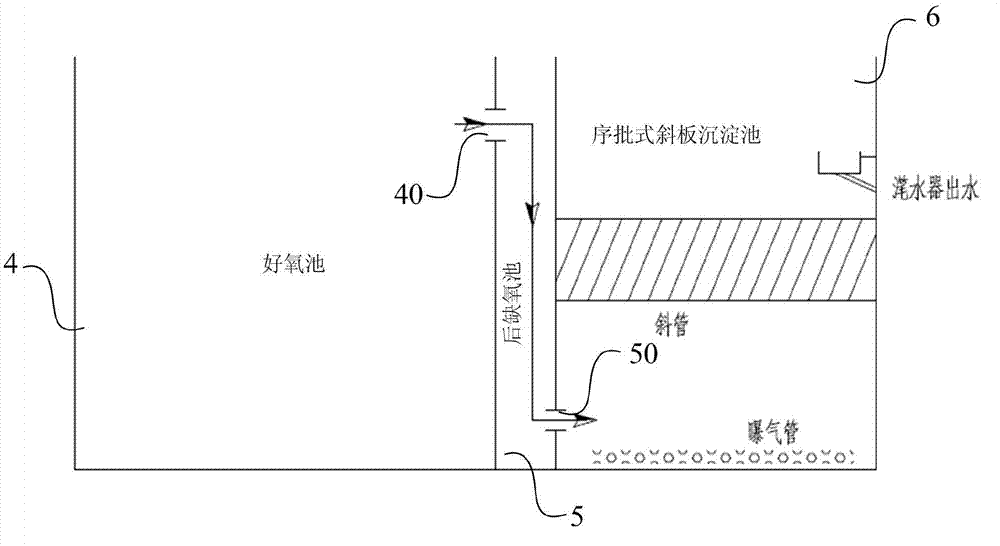

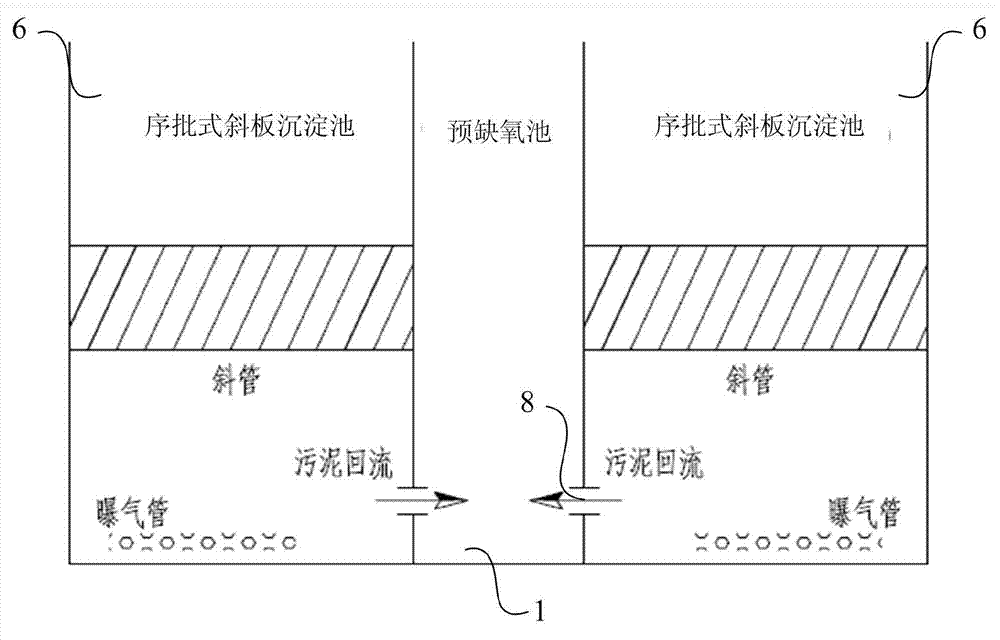

[0026] figure 1 It is a schematic diagram of the sewage treatment system of the present invention, figure 2 for figure 1 The 1-1 cutaway diagram, image 3 for figure 1 2-2 Sectional Drawing. As shown in the figure, the sewage treatment system of the present invention includes a pre-anoxic tank 1, an anaerobic tank 2, an anoxic tank 3, an aerobic tank 4, a post-anoxic tank 5, and a sequence batch type inclined plate sedimentation tank 6.

[0027] Further, the pre-anoxic pool 1, the anaerobic pool 2, the anoxic pool 3, the aerobic pool 4, the post-anoxic pool 5, and the sequence batch type inclined plate sedimentation pool 6 are connected through water holes in the partition wall.

[0028] The pre-anoxic tank 1 is connected with the water inlet pipe 7, and is used for the anoxic denitrification reaction of returnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com