Biaxial orienting drawing formed polyvinyl alcohol membrane and production method thereof

A technology of polyvinyl alcohol film and polyvinyl alcohol, which is applied in the field of high-end packaging applications, can solve the problems of close melting temperature and decomposition temperature, difficult thermoplastic processing, etc., and achieve excellent processing fluidity, good formability, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

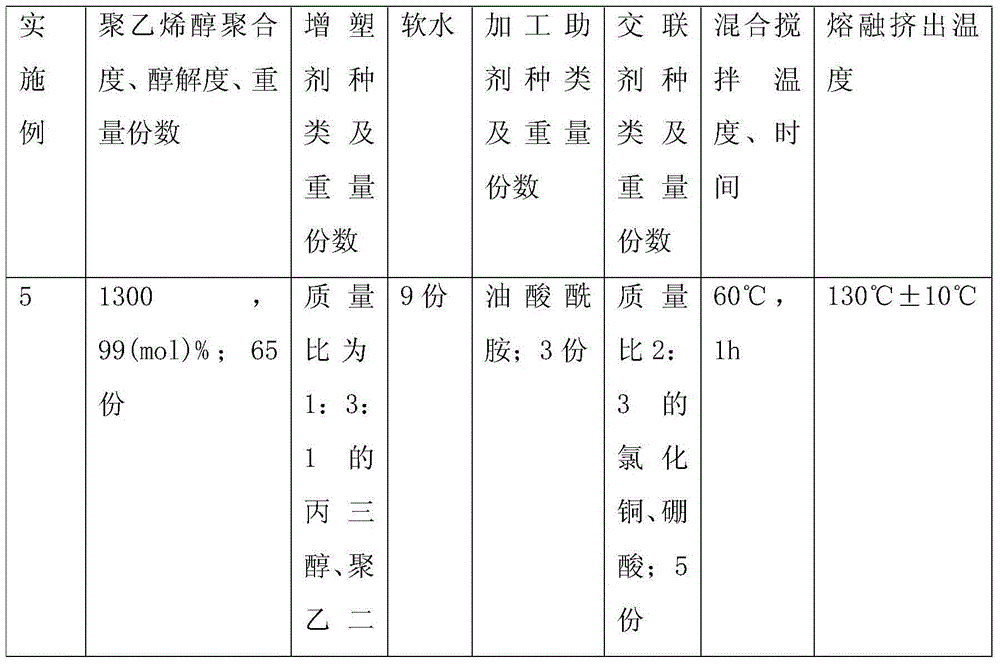

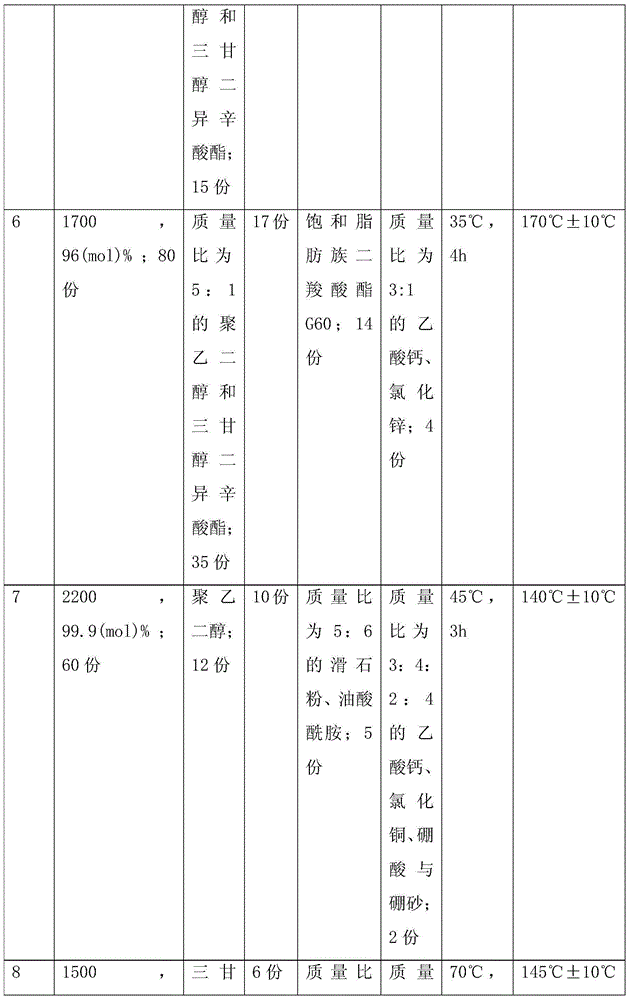

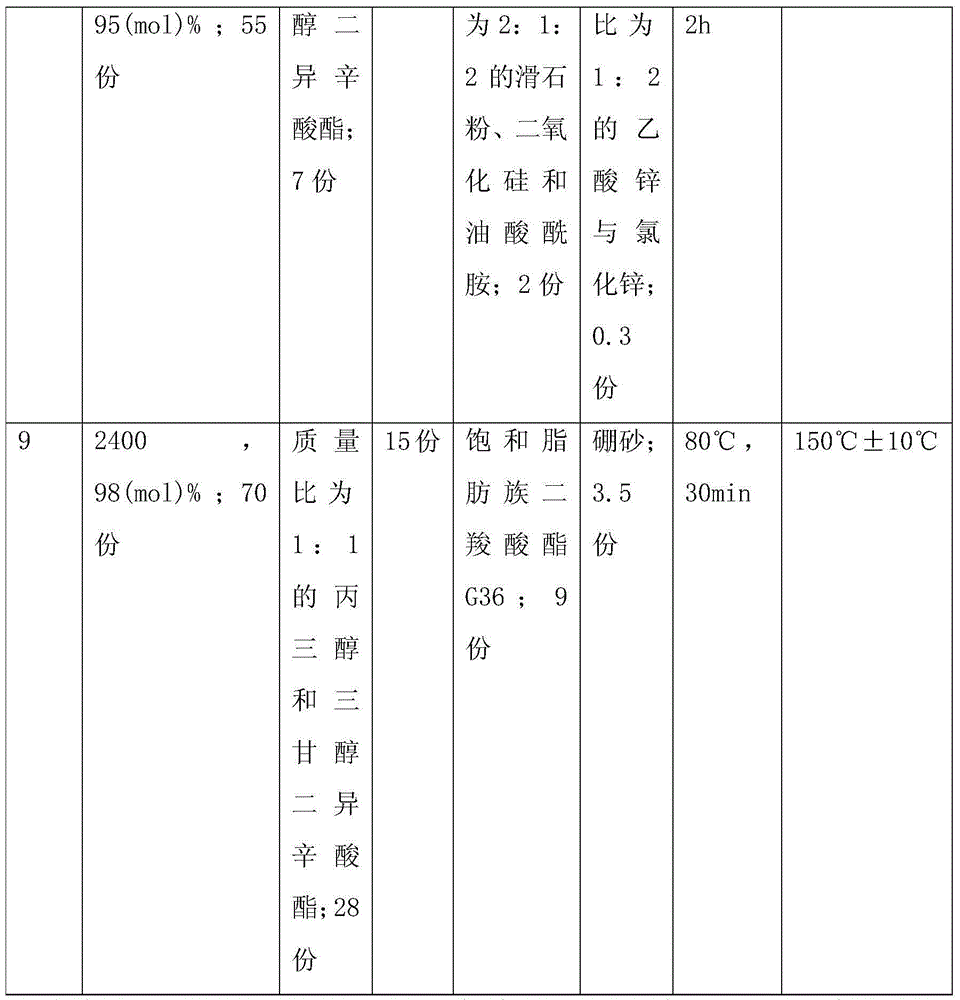

Examples

Embodiment 1

[0040] Example 1: 50 parts of polyvinyl alcohol (polymerization degree 2000, degree of alcoholysis 95.0 (mol) %), 6 parts of triethylene glycol diisocaprylate, 5 parts of soft water, 0.1 part of saturated aliphatic dicarboxylic acid ester G32 Mix well under stirring state, heat at 90°C while stirring, stop heating after 7h. Then put the material into the silo with stirring, use the screw to automatically transport the material to the screw extruder, keep the screw temperature at 200°C, melt and extrude under normal pressure, then cool the material to 40°C, and cut Granular melt-processable polyvinyl alcohol resin is produced by granulating and molding by a granulator. The obtained thermoplastic polyvinyl alcohol resin is heated to a molten state, extruded by a screw and biaxially stretched, and subjected to thermoplastic processing to form a polyvinyl alcohol film. Biaxially stretched film is formed by single-screw melt extrusion to form a thin sheet, and then biaxially stret...

Embodiment 2

[0043] Embodiment 2: 85 parts of polyvinyl alcohol (polymerization degree 2400, alcoholysis degree 97.0 (mol) %), 20 parts of polyethylene glycol, 20 parts of glycerol, 20 parts of soft water, 10 parts of silicon dioxide, 5 parts Oleic acid amide was mixed evenly under stirring, and heated while stirring at a temperature of 30°C, and stopped heating after 10 hours. Then put the material into the silo with stirring, use the screw to automatically transport the material to the single-screw extruder, keep the temperature of the screw at 120°C, melt and extrude the material under the pressure of 0.01MPa (gauge pressure), and then cool the material To 20 ℃, through pelletizer pelletizing and molding to produce polyvinyl alcohol resin that can be melt-processed. The obtained thermoplastic polyvinyl alcohol resin is heated to a molten state, extruded by a screw and biaxially stretched, and subjected to thermoplastic processing to obtain a high-temperature water-soluble polyvinyl alco...

Embodiment 3

[0046] Embodiment 3: with 70 parts of conventional polyvinyl alcohol (polymerization degree 1000, degree of alcoholysis 99.9 (mol) %), 30 parts of polyethylene glycols, 16 parts of soft water, 7 parts of saturated aliphatic dicarboxylic acid ester G36, 3 parts Mix the silica evenly, heat at 55°C for 2h, and then stop heating. Then put the material into a single-screw extruder, keep the screw temperature at 145°C, melt and extrude it under normal pressure, then cool the material to 25°C, and pelletize it with a pelletizer to obtain a melt-processable polyvinyl alcohol resin . The obtained thermoplastic polyvinyl alcohol resin is heated to a molten state, extruded by a screw and biaxially stretched, and subjected to thermoplastic processing to obtain a high-temperature water-soluble polyvinyl alcohol film. mentioned. Biaxially stretched film is formed by single-screw melt extrusion to form a thin sheet, and then biaxially stretched to form a film. The aspect ratio of the scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com