Sulfonation reaction cooling method in acesulfame synthesis technology

A technology of sulfonation reaction and synthesis process, which is applied in the field of sulfonation reaction cooling in the synthesis process of acesulfame potassium, can solve the problems of large influence of brine pump efficiency and large cooling loss in the control process, so as to reduce equipment purchase and installation costs and maintenance. Maintenance cost, effect of eliminating constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

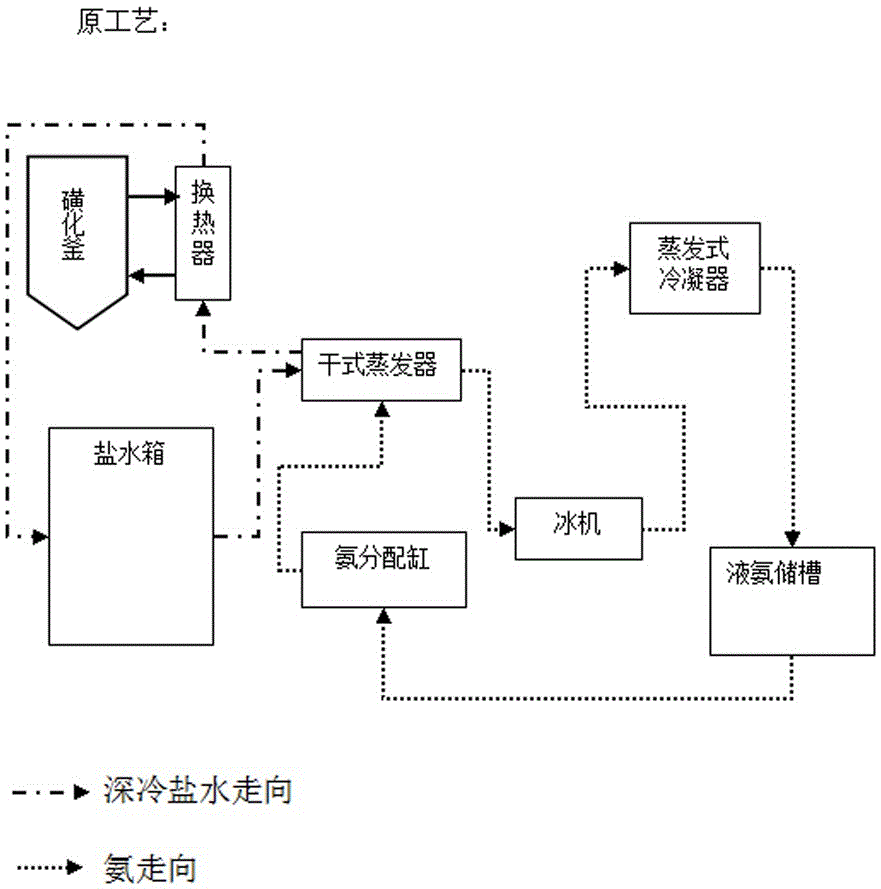

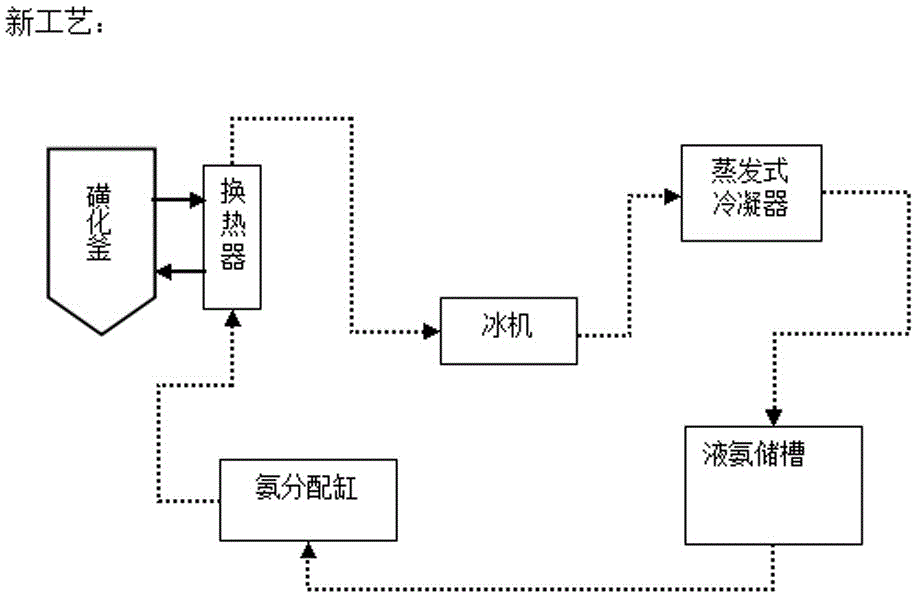

[0008] like figure 2 As shown, the present invention provides a method for cooling the sulfonation reaction in the synthesis process of acesulfame potassium, which utilizes the characteristics of low specific gravity and low boiling point of liquid ammonia to take away the heat of the sulfonation reaction through the sublimation of liquid ammonia to achieve the purpose of cooling. Liquid ammonia is used instead of the traditionally used cryogenic brine as a coolant to enter the heat exchanger to directly cool down the sulfonation tank, and the temperature in the sulfonation tank is controlled by adjusting the flow rate of liquid ammonia to meet the temperature requirements of the sulfonation reaction.

[0009] Specific steps:

[0010] 1) Turn on the sulfonation circulating pump to make the material enter the heat exchanger tube;

[0011] 2) Turn on the ice machine, turn on the evaporative condenser, and turn on the ammonia valve to allow liquid ammonia to enter the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com