Technique for continuously producing high purity hydrogen by water electrolysis

A technology of water electrolysis and high-purity hydrogen, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems such as the impact of high-purity hydrogen recovery rate, achieve high recovery rate, high recovery rate, and low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

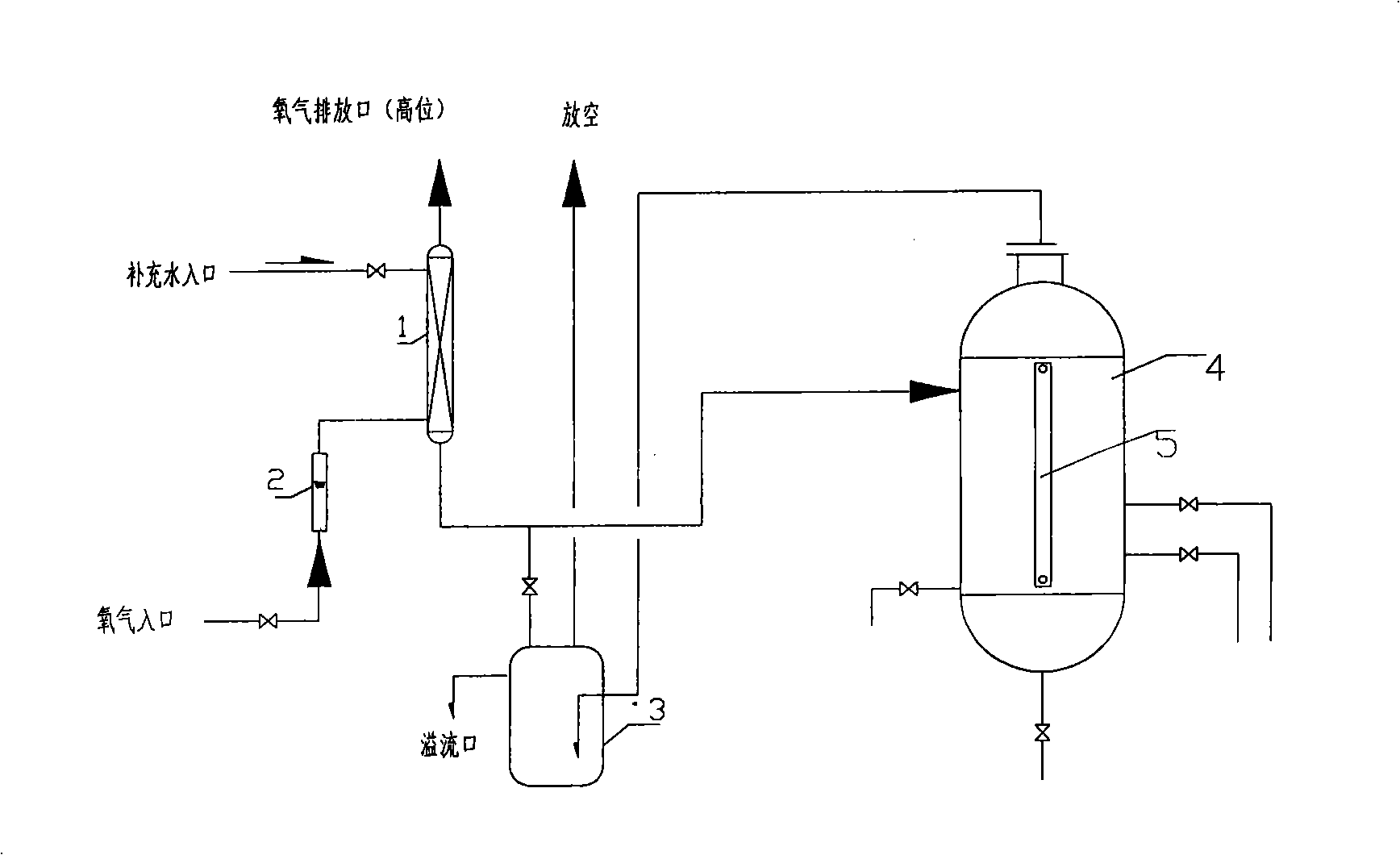

[0040] In this embodiment, the continuous production of water electrolysis conforms to the national GB / T 7445 high-purity hydrogen industrial device for water electrolysis hydrogen production. The rated hydrogen production capacity is 60Nm 3 / h, the hydrogen output pressure is 1.2MPa, the output purity varies with the operating conditions, the lowest is 99.6%, and the highest can reach 99.9%. After the device was repurchased, it was modified to produce high-purity hydrogen: an oxygen inlet and an oxygen flow meter 2 were added to the inlet of the raw water, a packing pipe 1 filled with stainless steel mesh was used as a bubbling denitrification pipe, and the raw water tank 4 was Change the opening into a seal, and connect a water-sealed tank 3 through a pipeline on the top of the water tank, so that the air on the water surface of the raw water tank is emptied through the water-sealed tank 3, see figure 1 .

[0041] The high-purity hydrogen continuous production process of th...

Embodiment 2

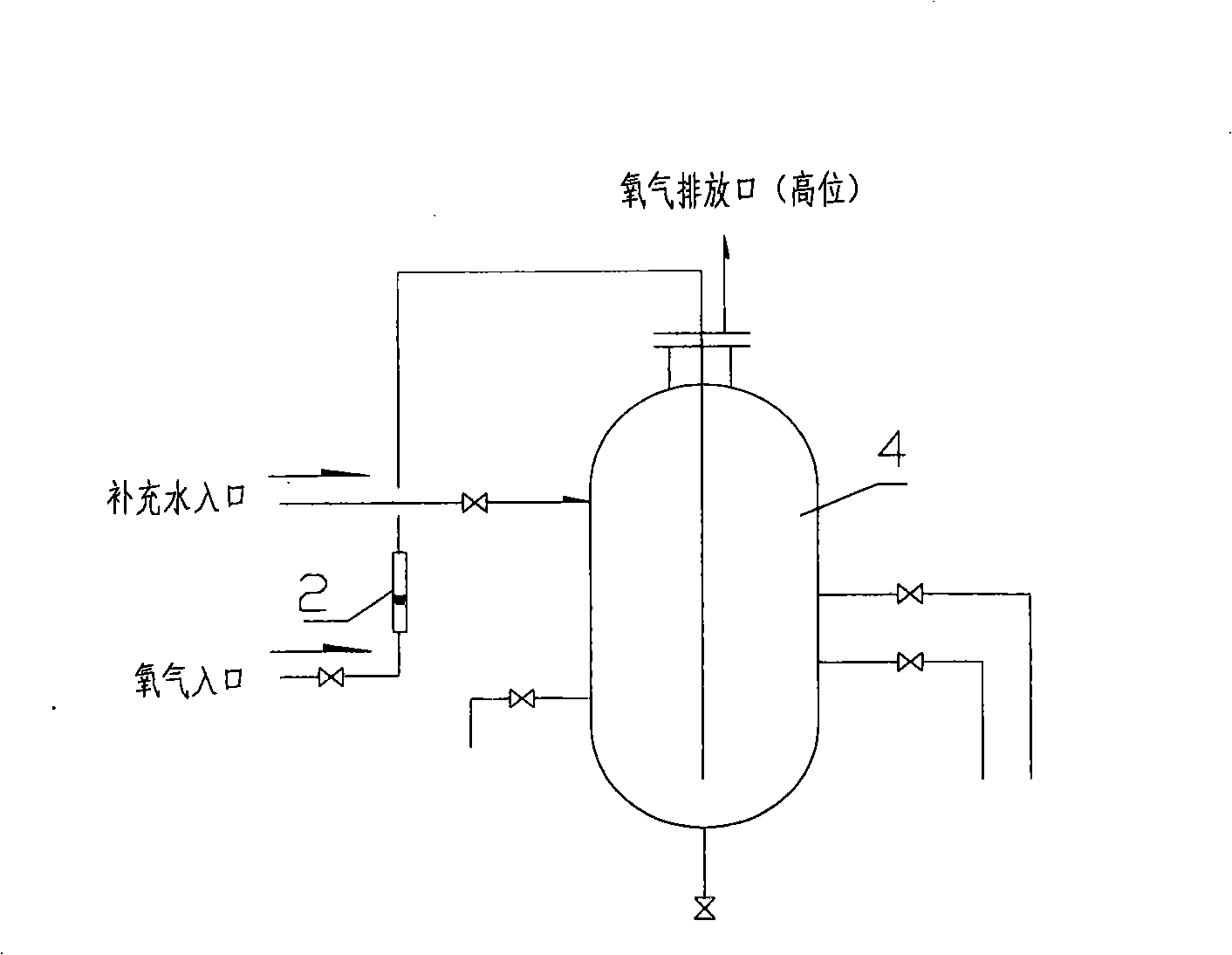

[0049] In this embodiment, the continuous production of water electrolysis meets the national standard GB / T 7445 high-purity hydrogen. The rated hydrogen production capacity of the water electrolysis hydrogen production industrial device is 100Nm 3 / h, the hydrogen output pressure is 3.2MPa, the output purity varies with the operating conditions, the lowest is 99.6%, and the highest can reach 99.9%. After installation, acceptance and trial production of the device for a period of time, it will be modified to produce high-purity hydrogen: add an oxygen inlet and oxygen flow meter 2 at the raw water inlet, see figure 2 .

[0050] The high-purity hydrogen continuous production process of this embodiment mainly includes the following steps:

[0051] (1) Removal of dissolved gas in raw water: at normal temperature and pressure, the flow rate is 0.2-1.0Nm 3 / h of oxygen in the raw water tank 4 is used to blow back the raw water by bubbling to remove nitrogen and other gaseous imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com