Method for realizing closed cycle of dyeing waste water

A technology for printing and dyeing wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as pollution, achieve process stability and easy industrial application , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

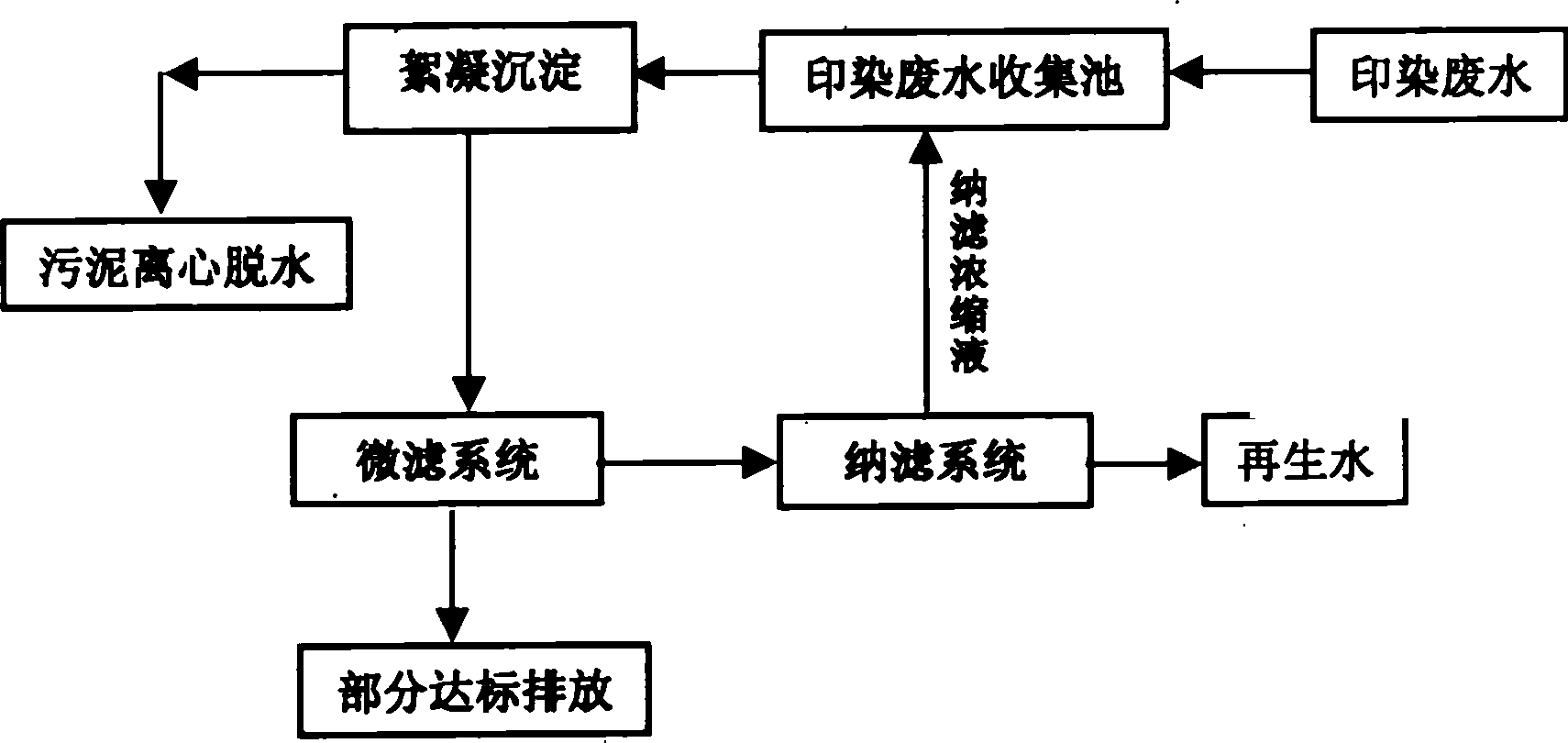

[0025] Embodiment 1: as figure 1 Shown, the processing method of printing and dyeing waste water closed loop, comprises the following steps:

[0026] 1) Put the printing and dyeing wastewater into the printing and dyeing wastewater collection tank, use mechanical stirring to clarify the tank, add flocculant and coagulant aid, and the residence time is 20min. The flocculant used in the flocculation and precipitation process is polyaluminum chloride PAC, and the amount of PAC The coagulation aid is polyacrylamide PAM, and the amount of PAM added is 0.5mg / L. The generated sludge is dehydrated by a centrifuge; the COD of the supernatant after flocculation and precipitation is <150mg / L, and the conductivity Rate<400μs / ms, turbidity<30mg / L, SS<60mg / L, chroma<60 times, printing and dyeing wastewater removes more than 50% of chroma and COD through flocculation and sedimentation. Printing and dyeing wastewater is removed by flocculation and sedimentation process to remove chroma and C...

Embodiment 2

[0030] Embodiment 2: as figure 1 Shown, the processing method of printing and dyeing waste water closed loop, comprises the following steps:

[0031] 1) Put the printing and dyeing wastewater into the printing and dyeing wastewater collection tank, use mechanical stirring to clarify the tank, add flocculant and coagulant aid, and the residence time is 20min. The flocculant used in the flocculation and precipitation process is polyaluminum chloride PAC, and the amount of PAC The coagulant aid is polyacrylamide PAM, and the amount of PAM added is 1mg / L. The generated sludge is dehydrated by a plate and frame filter press; the COD of the supernatant after flocculation and precipitation is <150mg / L. Conductivity<400μs / ms, turbidity<30mg / L, SS<60mg / L, chroma<60 times, printing and dyeing wastewater removes more than 50% of chroma and COD through flocculation and sedimentation.

[0032] 2) The supernatant separated by flocculation and precipitation enters the microfilter to remove ...

Embodiment 3

[0035] Embodiment 3: as figure 1 Shown, the processing method of printing and dyeing waste water closed loop, comprises the following steps:

[0036] 1) Put the printing and dyeing wastewater into the printing and dyeing wastewater collection tank, use mechanical stirring to clarify the tank, add flocculant and coagulant aid, and the residence time is 20min. The flocculant used in the flocculation and precipitation process is polyaluminum chloride PAC, and the amount of PAC The coagulation aid is polyacrylamide PAM, and the amount of PAM added is 0.75mg / L. The generated sludge is dehydrated by a centrifuge; the COD of the supernatant after flocculation and precipitation is less than 150mg / L, and the conductivity Rate<400μs / ms, turbidity<30mg / L, SS<60mg / L, chroma<60 times, printing and dyeing wastewater removes more than 50% of chroma and COD through flocculation and sedimentation.

[0037] 2) The supernatant separated by flocculation and precipitation enters the microfilter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com