Corrosion and scale inhibition method for soft water closed circulation system

A circulating system, soft water sealing technology, applied in the field of water treatment, can solve the problems of poor anti-corrosion ability, high cost of use, environmental pollution, etc., and achieve the effect of improved corrosion inhibition performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

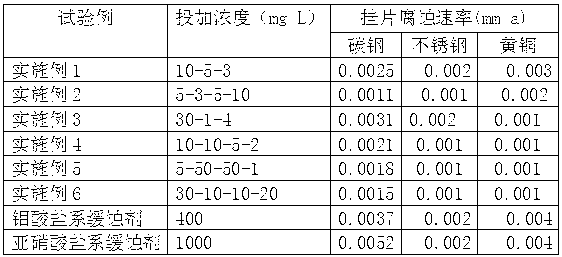

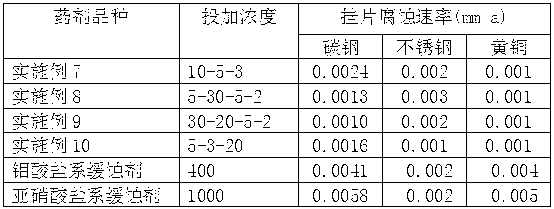

Embodiment 1

[0023] The water quality conditions of the treated soft water closed circulation system are: the hardness (calculated as calcium carbonate) is 5mg / L, the pH value of the soft water is adjusted to 9.0 with sodium carbonate, and then 10mg / L of methyl oxime is added to remove dissolved oxygen, and then hydroxyethyl Forked bisphosphonic acid 5mg / L, add benzotriazole 3mg / L. During implementation, the benzotriazole can be dissolved in desalinated water first.

Embodiment 2

[0025] The water quality conditions of the treated soft water closed circulation system are the same as in Example 1; the pH value of the soft water is adjusted to 8.8 with sodium carbonate, and 5 mg / L of carbohydrazide is added to remove dissolved oxygen, and then 2-phosphate-1,2,4- Tricarboxylic acid butane 3mg / L, add phosphonocarboxylic acid copolymer 5mg / L, add benzotriazole 10mg / L. During implementation, the benzotriazole can be dissolved in desalinated water first.

Embodiment 3

[0027] The water quality conditions of the treated soft water closed circulation system are the same as in Example 1; the pH value of the soft water is adjusted to 8.5 with sodium carbonate, and 30 mg / L of diethylhydroxylamine is added to remove dissolved oxygen, then sodium polyacrylate 1 mg / L is added, and sodium borate is added 4mg / L. During implementation, sodium borate can be dissolved with desalinated water earlier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com