Method for exploiting coal bed gas by hydraulic drilling and pressure relieving

A coalbed methane and hydraulic technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of limited hole diameter, unsafety and environmental pollution, and achieve the effect of convenient construction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

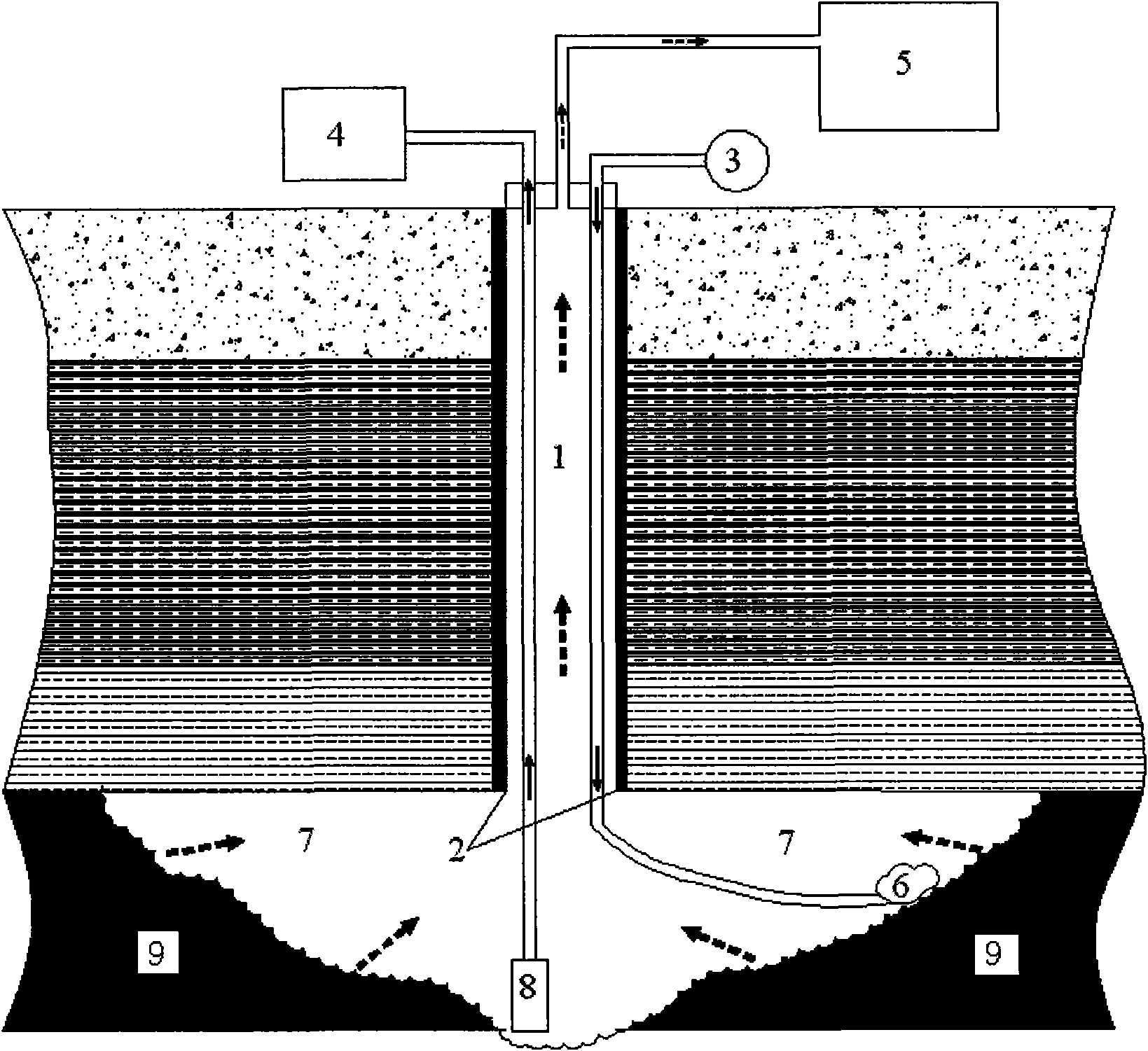

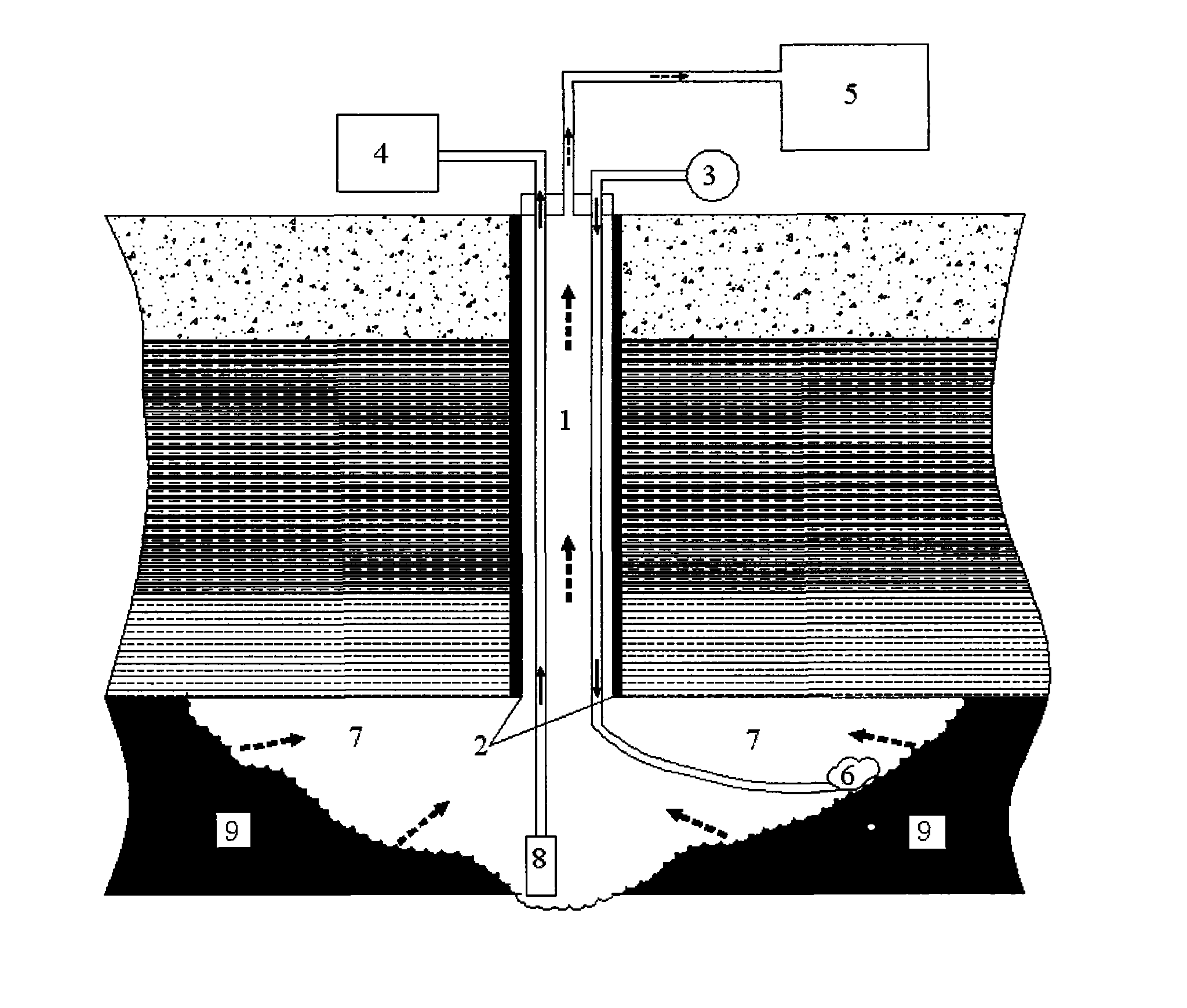

[0021] The present invention will be further described below in conjunction with an embodiment (accompanying drawing):

[0022] As shown in the figure, the method for exploiting coalbed methane by hydraulic digging and pressure relief of the present invention includes the following steps:

[0023] (1) Set the coalbed methane production well 1. Use a large-diameter drilling rig, pass through the roof of the coal seam and enter a little bit of the coal seam 9, and set up a coalbed methane exploitation well 1 capable of water injection, drainage, and gas output; Use known methods to securely connect.

[0024] (2) mechanical hole digging. After the coalbed methane extraction well is completed, the coal seam 9 is excavated using existing mechanical excavation tools, and the cave is as large as possible.

[0025] (3) Lower the flushing robot 6. The cave is completed, and the explosion-proof submersible flushing robot 6 is lowered from the side of the coalbed methane mining well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com