Preparation method of blocky SiO2-Y2O3 compound aerogel

A composite airgel, sio2-y2o3 technology, applied in the field of preparation of bulk SiO2-Y2O3 composite airgel, can solve the problems of poor thermal stability at high temperature, and achieve the effect of improving thermal stability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

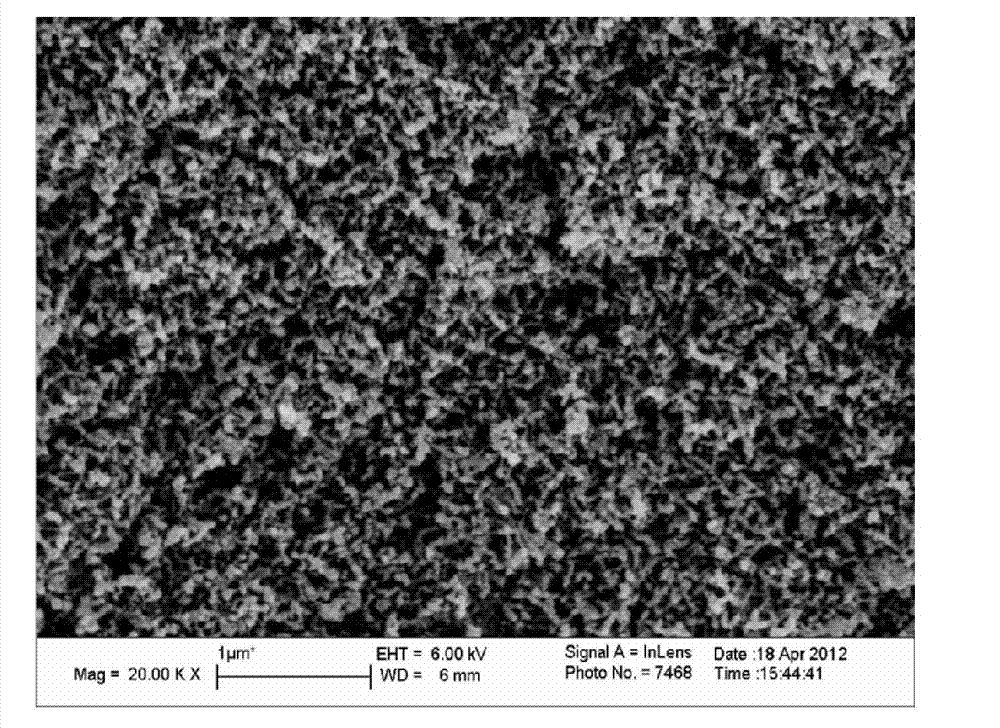

Image

Examples

example 1

[0021] Tetraethyl orthosilicate, hydrochloric acid, deionized water, and absolute ethanol were mixed in a molar ratio of 1:0.1:8:10 at 45°C and stirred for 90 minutes to obtain a clear transparent solution. Then add yttrium chloride hexahydrate to the clear solution according to the molar ratio of tetraethylorthosilicate and yttrium chloride hexahydrate at 1:0.05, and continue to stir evenly at 60°C for 120 minutes to obtain a colorless transparent solution. Finally, add ammonia water to the colorless transparent solution and adjust the pH value of the mixed solution to 6.8 to obtain SiO 2 -Y 2 o 3 Composite sol solution. SiO will be obtained 2 -Y 2 o 3 Pour the composite sol solution into the mold and place it in an oven at 40°C for 3 hours to react at a constant temperature to obtain SiO 2 -Y 2 o 3 Composite wet gel. Then add ethanol aging solution to the sample in the mold for aging treatment, solvent replacement 3 times, each 24h, and finally get block SiO 2 -Y ...

example 2

[0023] Tetraethyl orthosilicate, hydrochloric acid, deionized water, and absolute ethanol were mixed in a molar ratio of 1:0.02:6:15 at 50°C and stirred for 120 minutes to obtain a clear transparent solution. Then add yttrium chloride hexahydrate to the clear solution according to the molar ratio of tetraethylorthosilicate and yttrium chloride hexahydrate at 1:0.03, and continue to stir evenly at 65°C for 100 minutes to obtain a colorless transparent solution. Finally, add ammonia water to the colorless transparent solution and adjust the pH value of the mixed solution to 7.5 to obtain SiO 2 -Y 2 o 3 Composite sol solution. SiO will be obtained 2 -Y 2 o 3The composite sol solution was poured into the mold and placed in a 40°C oven for constant temperature reaction for 1h to obtain SiO 2 -Y 2 o 3 Composite wet gel. Then add ethanol aging solution to the sample in the mold for aging treatment, solvent replacement 5 times, each 12h, and finally get block SiO 2 -Y 2 o ...

example 3

[0025] Tetraethyl orthosilicate, hydrochloric acid, deionized water, and absolute ethanol were mixed in a molar ratio of 1:0.2:10:20 at 30°C and stirred for 30 minutes to obtain a clear transparent solution. Then add yttrium chloride hexahydrate to the clear solution according to the molar ratio of tetraethylorthosilicate and yttrium chloride hexahydrate at 1:0.005, and continue to stir evenly at 70°C for 80 minutes to obtain a colorless transparent solution. Finally, add ammonia water to the colorless transparent solution and adjust the pH of the mixed solution to be 8 to obtain SiO 2 -Y 2 o 3 Composite sol solution. SiO will be obtained 2 -Y 2 o 3 Pour the composite sol solution into the mold and place it in an oven at 30°C for 5 hours to react at a constant temperature to obtain SiO 2 -Y 2 o 3 Composite wet gel. Then add acetone aging solution to the sample in the mold for aging treatment, solvent replacement 4 times, 24 hours each time, and finally obtain block Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com