Preparation method of polyolefin microporous film

A technology of polyolefin microporous membrane and polypropylene, which is applied in the direction of flat products, applications, coatings, etc., can solve the problems of poor uniformity of microporous membrane pores, complicated preparation process, and low production rate, and achieve uniform pores and low equipment investment. Small, high production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

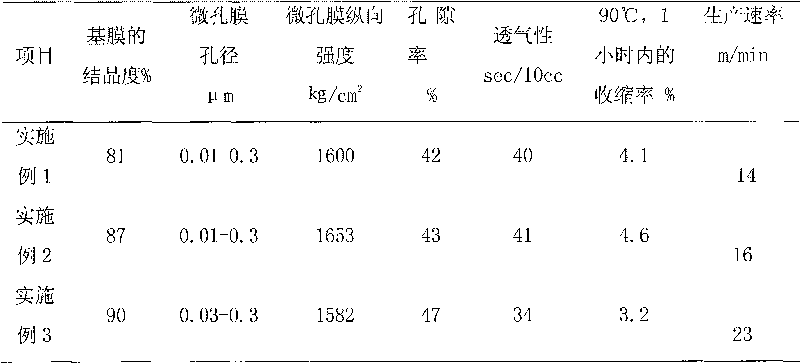

Examples

Embodiment 1

[0018] Using polypropylene as raw material, its index is average molecular weight 300000, density 0.902g / cm 3 , melt index 3.0 g / 10 minutes. The specific process is:

[0019] A1. Casting to prepare the base film. Under the condition of 240 ° C, the raw material polypropylene is melted and extruded with a T-shaped casting head, the die opening is 1.2 mm, the temperature of the cooling roll is 30 ° C, and the drafting rate is 180 meters. / min to make a basement film;

[0020] B1, annealing treatment, put the base film prepared in step A1 into an oven for annealing treatment, the oven temperature is 150°C, and the annealing treatment time for the single-layer film is 15 minutes;

[0021] C1, multi-point stretching to form holes, the base film after the annealing treatment in step B1 is first cold-drawn at 20°C and a draw ratio of 350% / min to form silver streak defects, and then at a temperature of 145°C and 150 % / min under the stretching ratio of multi-point stretching to form...

Embodiment 2

[0024] Using polyethylene as raw material, its index is the average molecular weight of 200,000 and the density of 0.964g / cm 3 , High-density polyethylene with a melt index of 0.4 g / 10 minutes. The specific process is:

[0025] A2. Casting to prepare the base film. Under the condition of 200 ° C, the raw material polyethylene is melted and extruded with a T-shaped casting head, the die opening is 1.2 mm, the temperature of the cooling roll is 25 ° C, and the drafting speed is 180 meters. / min to make a basement film;

[0026] B2, annealing treatment, put the base film prepared in step A into an oven for annealing treatment, the temperature of the oven is 90°C, and the annealing treatment time for the single-layer film is 2 hours;

[0027] C2, multi-point stretching to form holes, the base film after the annealing treatment in step B is first cold-drawn at 28°C and a stretching ratio of 400% / min to form silver streak defects, and then at a temperature of 105°C and 150 % / min ...

Embodiment 3

[0030] Using polypropylene as raw material, its index is the average molecular weight of 300,000 and the density of 0.902g / cm 3 , melt index 3.0 g / 10 minutes.

[0031] The specific process is:

[0032] A3. Casting to prepare the base film, the raw material polypropylene is melted and extruded on a casting machine under the condition of 230° C., the die gap is 1.2 mm, the temperature of the cooling roll is 30° C., and the drawing speed is 180 m / min. Make basement membrane;

[0033] B3, annealing treatment, put the base film prepared in step A1 into an oven for annealing treatment, and anneal at 90°C, 105°C, and 120°C for 30 minutes;

[0034] C3, multi-point stretching to form holes, the base film after the annealing treatment in step B1 is first cold-drawn at 23°C and a stretching ratio of 400% / min to form silver streak defects, and then at a temperature of 140°C and Multi-point stretching at a stretching ratio of 150% / min to form a microporous structure;

[0035] D3, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com