Method for preparing propylene from methanol

A technology of methanol and propylene, applied in the field of propylene production, which can solve the problems of low propylene/ethylene ratio and less propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

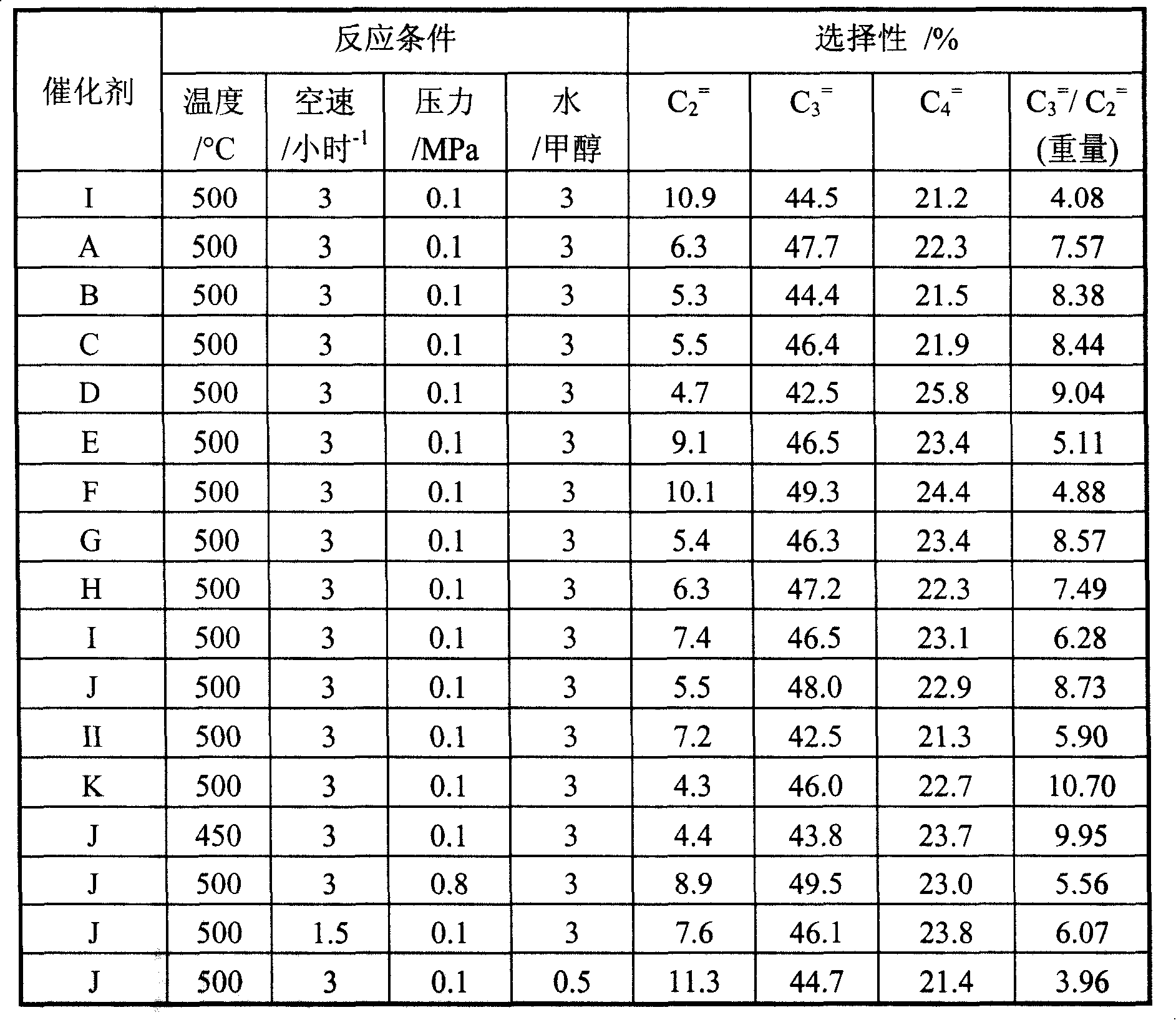

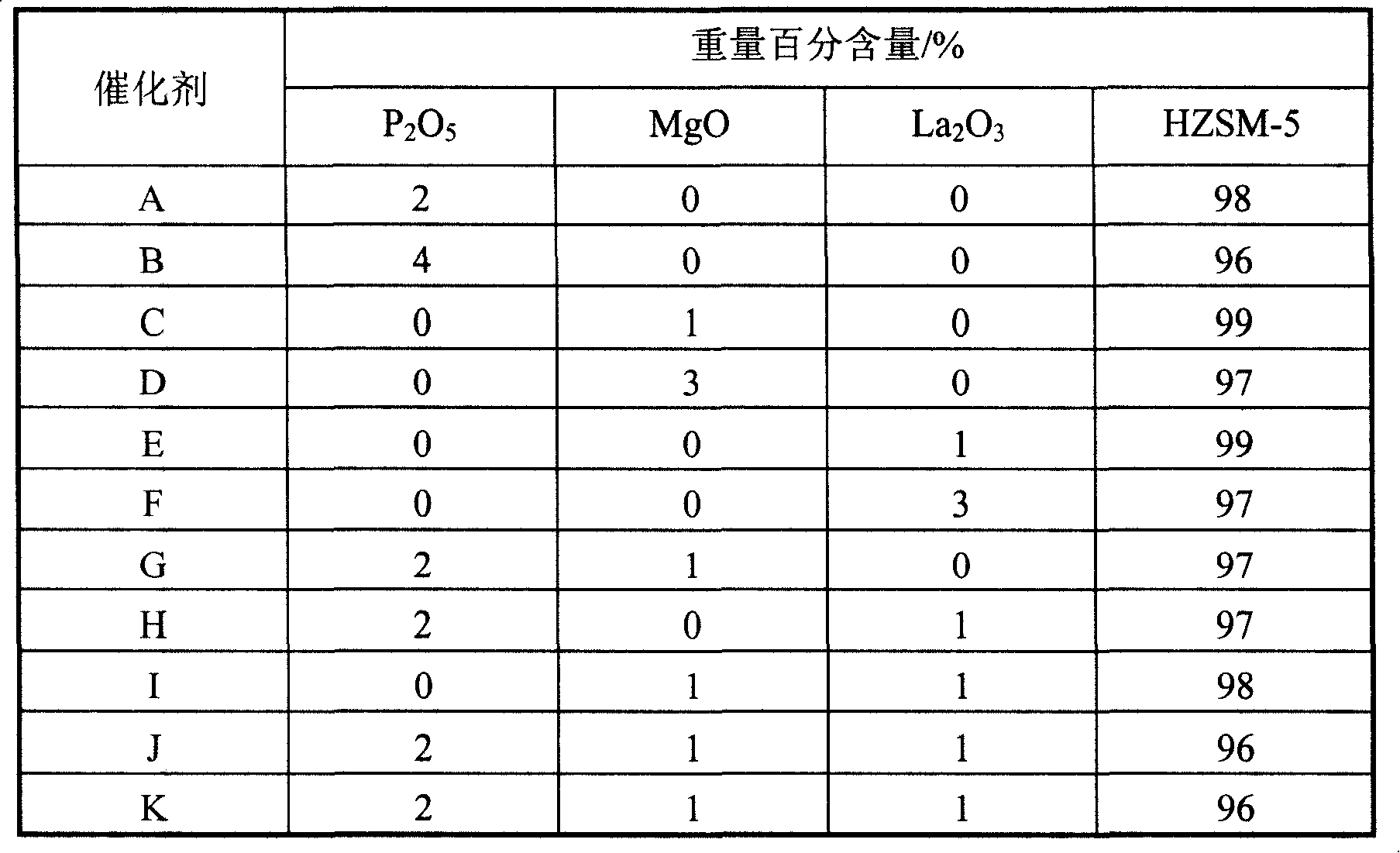

[0020] Adopt commercial HZSM-5 molecular sieve as raw powder, number I, SiO 2 / Al 2 o 3 The molar ratio is 100, and the weight fraction is 2% phosphorus (in P 2 o 5 After impregnation, it was placed at room temperature for 2 hours, then transferred to an oven for 2 hours at 120°C, and then transferred to a muffle furnace and roasted at 520°C for 4 hours to obtain catalyst A. After 40 mesh, it is used for the evaluation of methanol to propylene reaction, the reaction pressure is 0.1MPa, the temperature is 500°C, and the space velocity of methanol is 3 hours -1 , the water / methanol weight ratio is 3:1, and its reactivity is shown in Table-1.

Embodiment 2~10

[0022] Using the method of Example 1, phosphorus, magnesium, and lanthanum modified species were loaded on HZSM-5 molecular sieve I to obtain a series of catalysts with different loaded species or dosages, named catalysts B~J, and the compositions of each catalyst were listed in Table-2 , and then carry out the evaluation of methanol to propylene reaction according to the method of Example 1, and the reaction results are listed in Table-1.

Embodiment 12

[0024] Use commercial HZSM-5 molecular sieve as raw powder, number II, SiO 2 / Al 2 o 3 The molar ratio is 300, and the oxides of phosphorus, magnesium, and lanthanum are loaded by the equal impregnation method. The content is shown in Table-1, and the catalyst K is obtained, and then the methanol to propylene reaction is evaluated according to the method of Example 1, and the results are listed in the table. -1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com