Waste rubber tyre powder modified asphalt and its prepn process

A technology of composite modified asphalt and waste tire rubber powder, which is applied to building components, building insulation materials, construction, etc., and can solve problems such as unsuitable modification, poor performance, lagging research and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A chemical-physical method for preparing waste rubber powder modified road asphalt comprises the following steps: selecting waste rubber powder of 20-60 mesh. Will activate modifiers, solubilizers, sulfur and compatibilizers. According to a certain ratio, the amount of waste rubber powder is 10-30 parts by weight of the amount of asphalt, and it is kept at a temperature of 100-200°C for 10-120 minutes, and then added to the hot-melt asphalt at a temperature of 160-180°C. 1500-8000 rpm, stirring for 10-40 minutes to prepare road modified asphalt.

[0088] Described activation modifying agent comprises: methacrylic acid and its salt, glycidyl ester, ethanolamine and its salt, zinc stearate, stearic acid etc., preferably methacrylic acid and glycidyl ester, and its consumption is the amount of bitumen 0.1-40 parts by weight,

[0089] The solubilizing agent includes: furfural extracted oil, deasphalted oil, aromatic fraction oil or minus four-line fraction, tall oil and t...

Embodiment 2

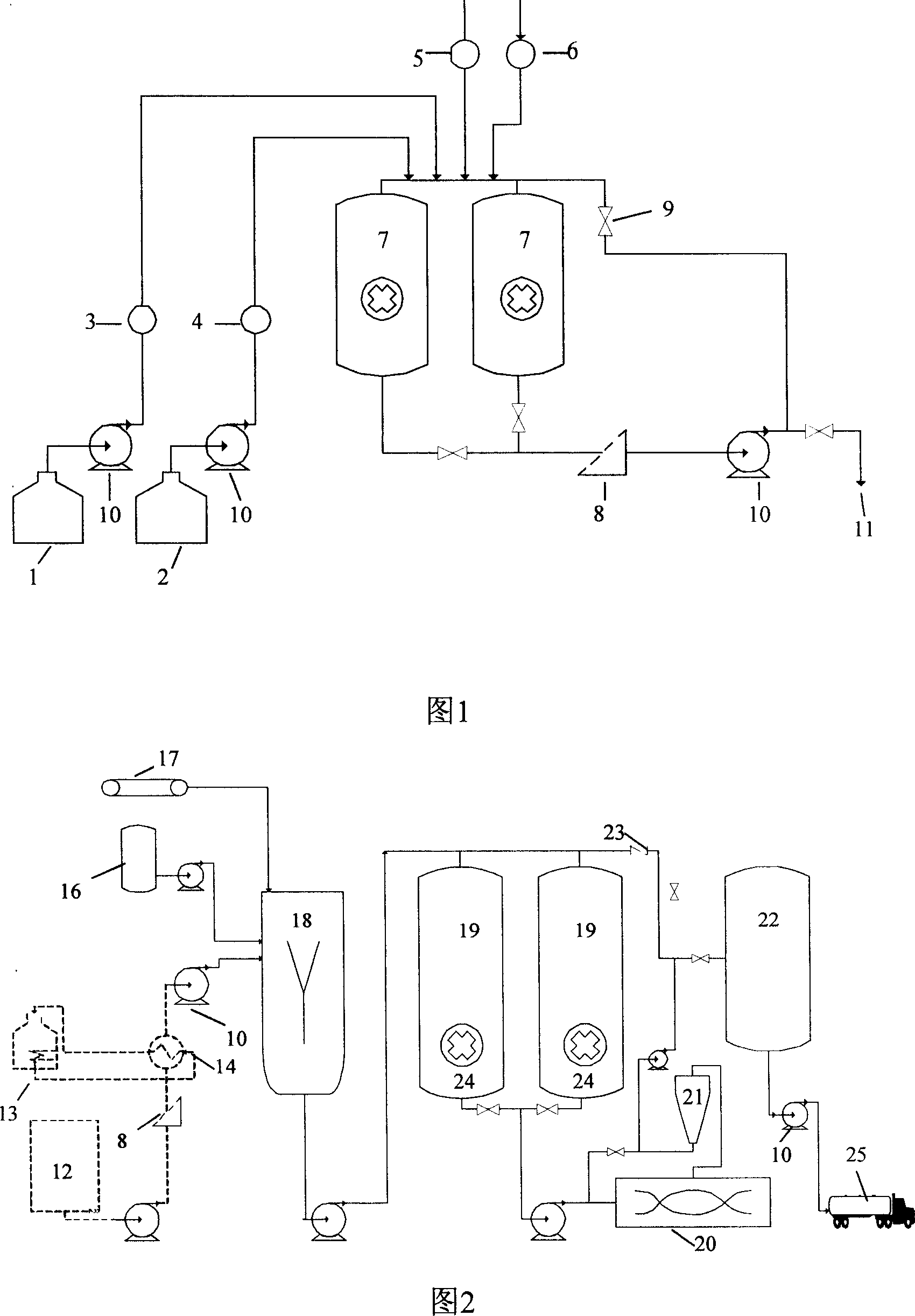

[0091]The preparation method of the modifier that the waste tire rubber powder meets the requirements of modified asphalt, the preparation process of the modifier is as shown in Figure 1: the activator 1, the solubilizing rubber powder 2, the rubber powder and other solubilizing agents are prepared in respective After the metering system 5 and 6 are metered, pump them into the modified liquid mixing tank. The modified reaction temperature is 140-160°C; The fully reacted mother liquor is directly pumped into the modified agent finished product tank 16 by the pump 10 after being filtered by the filter screen 8;

Embodiment 3

[0092] Embodiment 3 uses the preparation of modifying agent modified asphalt, and the preparation process is as shown in Figure 2: the base asphalt coming from the base asphalt tank 12 first passes through the filter screen 8 and the heat exchanger after exchanging heat with the heat exchanger and squeezes into the batching tank with a pump 8 ( 8); the asphalt modifier 16, stabilizer, modifier and other components 17 also enter the batching tank after passing through the metering system, the temperature of the batching tank is 160° C., and the residence time is 20 minutes. The intermediate products from the batching tank are poured into the asphalt swelling tank 19 respectively, and the asphalt swelling tank is stirred by the agitator 24, the swelling temperature is 180-200°C, and the residence time is 20-30min. The swollen intermediate product is sheared by the high-speed shearing machine 11 and then passed through the buffer tank 21 to become the finished modified asphalt pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com