Method and apparatus for fluid-liquid reactions

An equipment, fluid technology, applied in the field of fluid-liquid reaction, which can solve the problems of unfavorable after-sales service, flexibility and poor reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

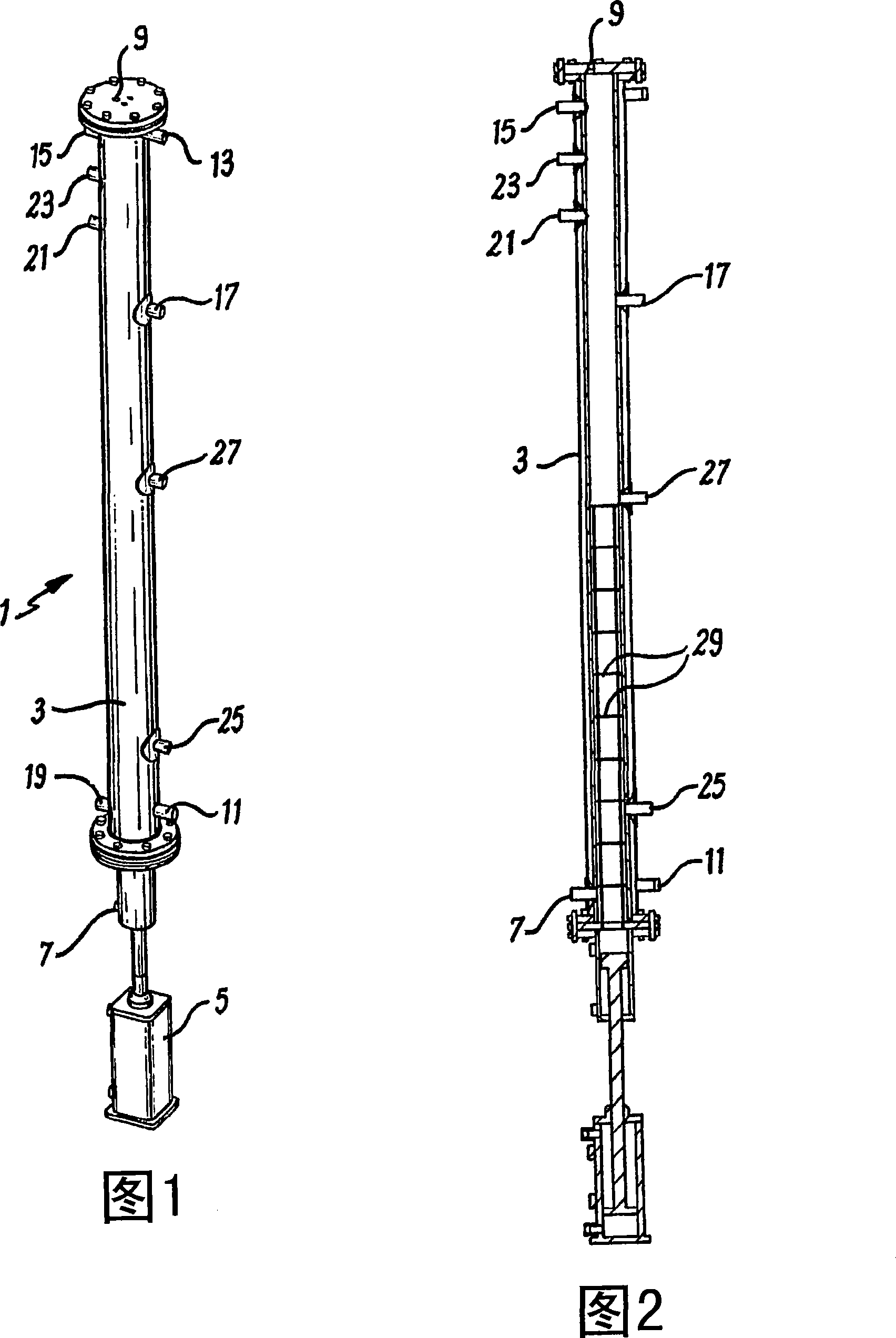

[0088] Figure 1 illustrates a reactor assembly 1 comprising a column 3, a piston 5, which in this example is equipped with a pneumatic hammer.

[0089] Arranged along the length of the shaft 3 are a number of inlet and outlet ports designed to allow the addition of reactants to and removal of products from the reactor, and additionally provide means for varying the temperature and pressure of the reactor. Detection device and method. In Figure 1, the hydrogen inlet 7 and inlet / outlet 9 are illustrated along with the reactant inlet 15, heating or coolant inlet 11 and heating or coolant outlet 13, product return port 19, product outlet 17, high and low level sensors 23 and 25, thermocouple 27 and pH sensor 21.

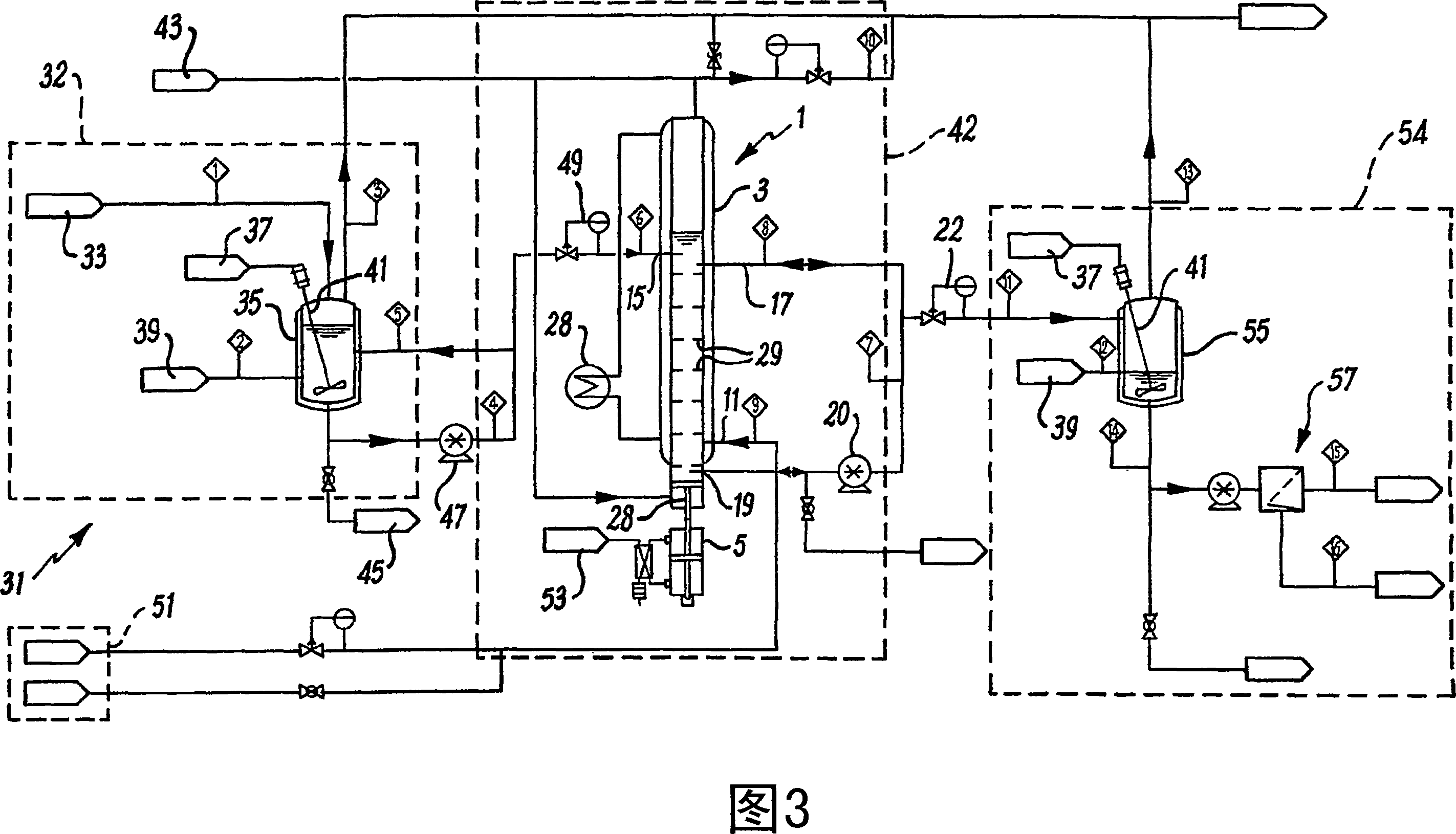

[0090] Figure 2 is a cross-sectional view of the reactor assembly of Figure 1 illustrating, in addition to the features of Figure 1 , fixed baffles 29 spaced along the length of the reactor. Furthermore, a pneumatic hammer 5 is shown. The pneumatic hammer 5 uses compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com