Agricultural waste dry-process anaerobic-fermentation automatic control device and automatic control operation method

An agricultural waste and dry anaerobic technology, which is applied in the field of automatic control devices for dry anaerobic fermentation of agricultural waste, can solve the problems of complex restart process, high cost, collapse, etc., so as to alleviate the problem of biomass energy substitution and ease The shortage of organic fertilizer, the effect of expanding new ways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

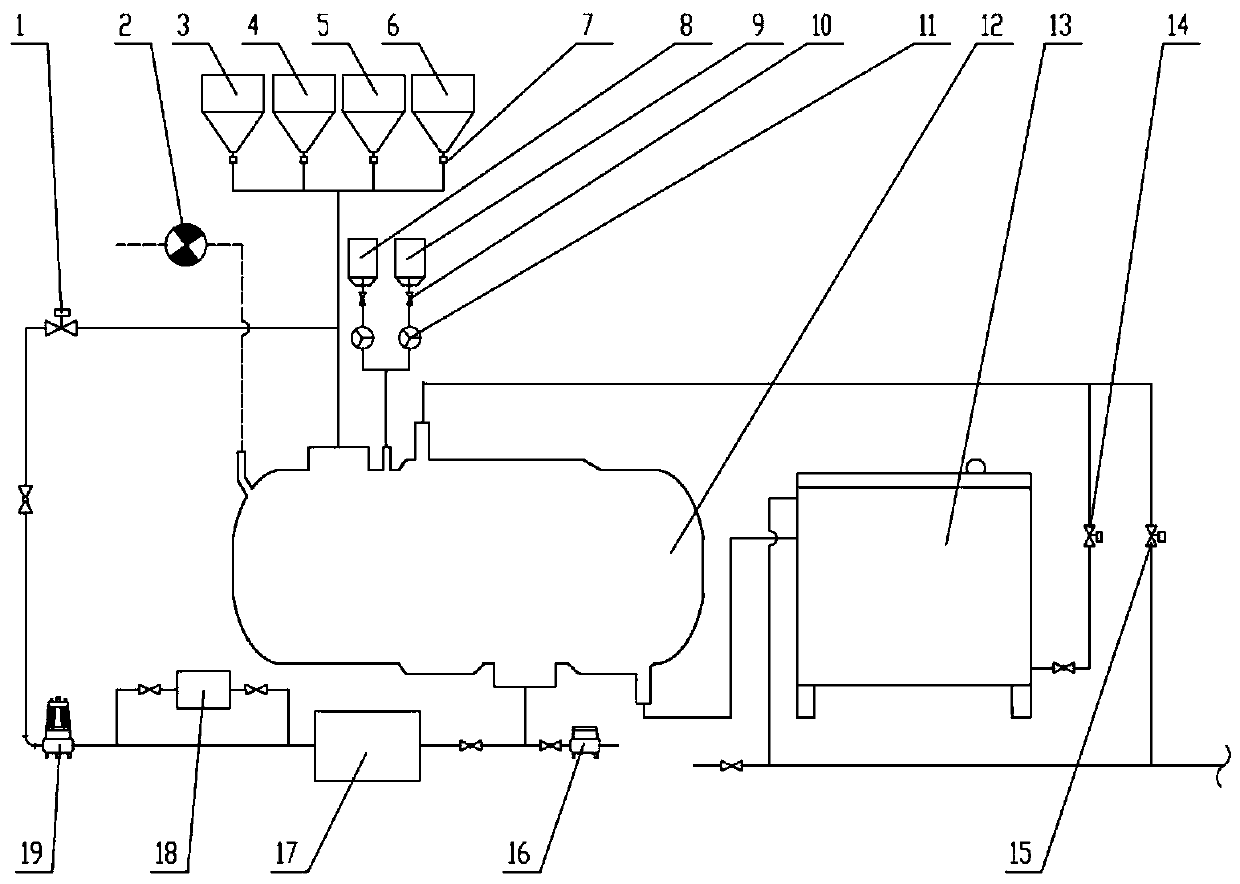

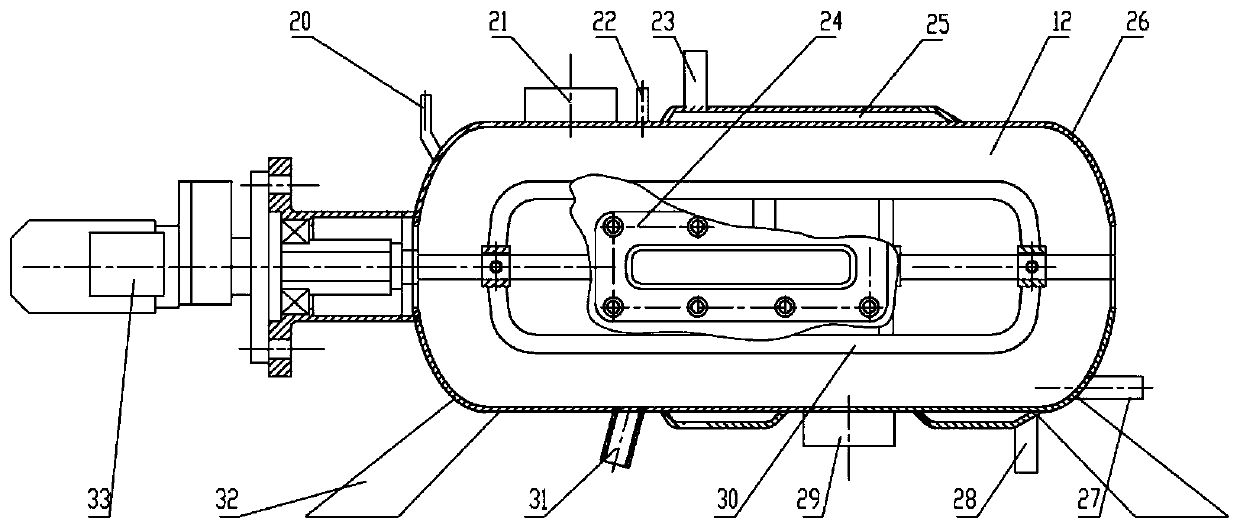

[0052] Such as figure 1 , figure 2 Shown, the present invention a kind of agricultural waste dry method anaerobic fermentation automatic control device (automatic agricultural waste dry method anaerobic fermentation device), it comprises a fermentation tank 12; Fermentation tank 12 tank bodies are made of stainless steel, horizontal type It is in the shape of a "capsule" with both ends closed; the fermenter 12 is arranged on the support 32 of the fermentation device, and the tank body is provided with a mirror window 24; the top of the tank body is provided with a feed port 21 (the feed port is provided with a seal The screw cap of ring), acid-base inlet 22; Tank body bottom is provided with discharge port 29 (discharge port 29 is connected with vacuum pump all the way, and another road is connected with solid-liquid separator 17, return pump 19 inlets successively, and return pump 19 The outlet is connected to the feed port 21), pH probe interface 31; the fermentation tank ...

Embodiment 2

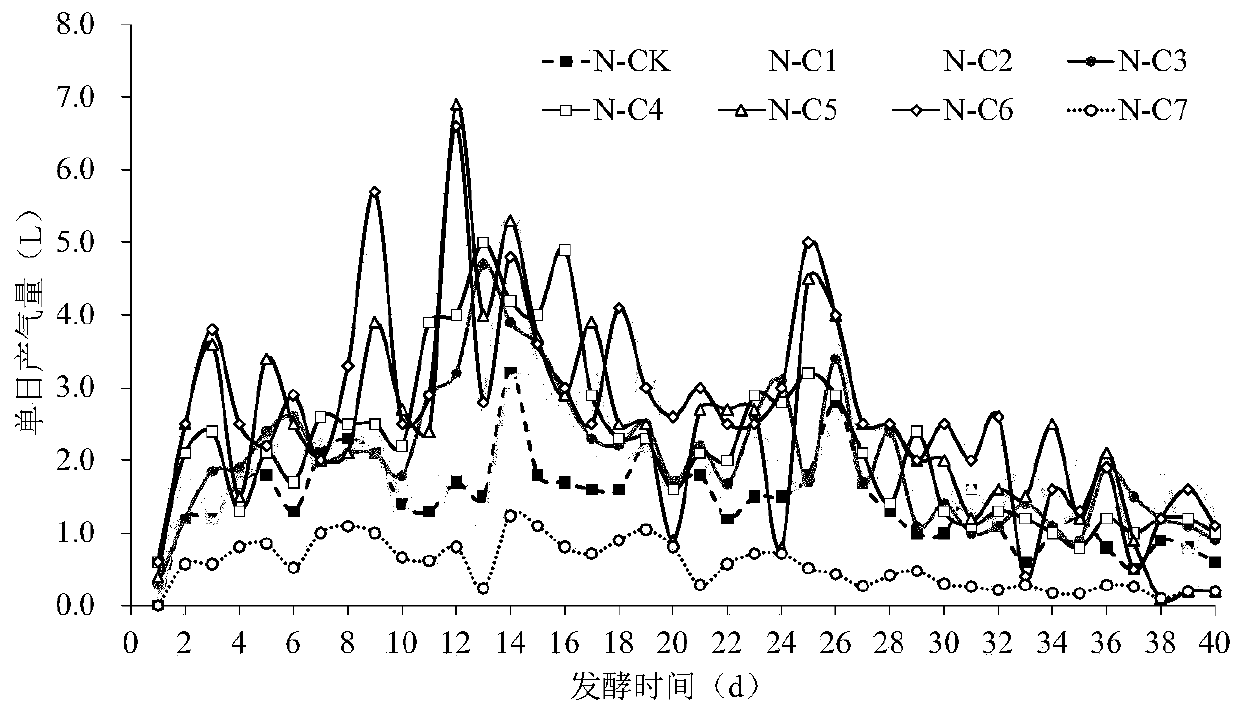

[0069] Example 2 Different N source addition amount treatment group

[0070] In this group of experiments, rice straw was used as the main reaction raw material, and by using different N source additions, the self-controlled dry anaerobic fermentation of agricultural waste was carried out by using the automatic control device and the automatic control operation method of the dry anaerobic fermentation of agricultural waste described in Example 1. Run the test to investigate the effect of different N source additions (that is, different C / N) on the gas production potential of straw.

[0071] 1. Experimental design and condition control

[0072] In areas where rice production is the main area, the main fermentation material is rice straw (rice straw). Considering that fresh pig manure is rich in organic and inorganic N and other nutrients such as S and P suitable for microbial activities, and has different types Anaerobic microorganisms are suitable as N source additives. In t...

Embodiment 3

[0090] Embodiment 3 different inoculum amount treatment groups

[0091] In this group of experiments, rice straw was used as the main reaction raw material, and by adding different proportions of exogenous inoculum, the dry anaerobic fermentation of agricultural waste was carried out by using the automatic control device and automatic control operation method for dry anaerobic fermentation of agricultural waste described in Example 1. The self-controlled operation test was conducted to investigate the effects of different inoculum on the gas production potential and fermentation efficiency (gas production efficiency) of straw.

[0092] 1. Experimental design and condition control

[0093] In the operation of anaerobic fermentation biogas production projects, it is often necessary to add a certain amount of inoculum rich in different types of anaerobic microorganisms at the feed end through measures such as biogas slurry reflux to improve gas production efficiency and increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com