PX oxidizing reactor for producing terephthalic acid

An oxidation reactor, terephthalic acid technology, applied in chemical instruments and methods, chemical methods for reacting liquids and gaseous media, organic chemistry, etc., can solve the high cost of agitators and compressors, PX and HAC consumption It can meet the requirements of uniform suspension of solids, avoid the deposition of crystals, and ensure safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

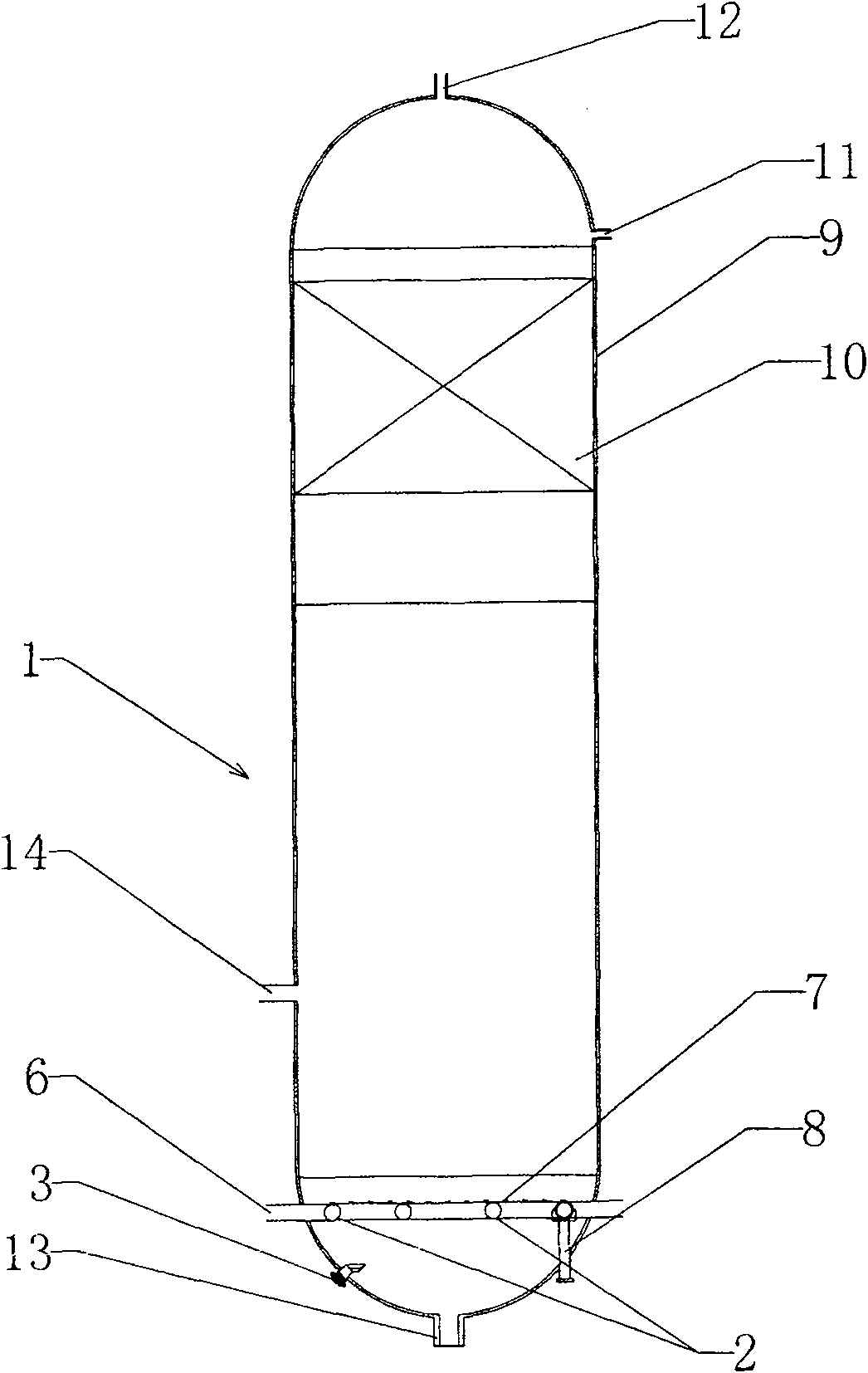

[0014] see Figure 1-2 , the PX oxidation reactor for producing terephthalic acid according to the present invention includes a reactor shell 1, and the bottom of the reactor shell 1 is provided with a distributed air intake device and a swirl air intake device.

[0015] The reactor shell 1 can generally be in the shape of a tank, and its height-to-diameter ratio is preferably 2.8-5. The superficial gas velocity of this height-to-diameter ratio is between the high-temperature and low-temperature reactors, which avoids large height-to-diameter ratios. The phenomenon of uneven distribution in the low-temperature reactor is superior to the high-temperature reactor in terms of low power consumption.

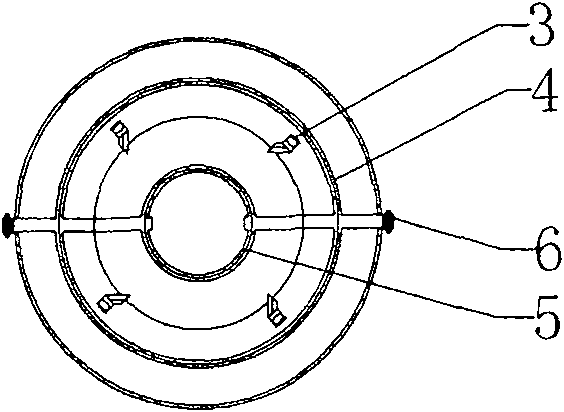

[0016] The distributed air intake device may include several air distribution pipes 2, the air distribution pipes 2 are in the shape of a ring, the center of which is on the vertical center line of the housing, and several ventilation holes 7 are provided on the pipe body, which Whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com