Micro-electrolysis catalysis strengthening hydrolytic acidification reactor

A technology of hydrolytic acidification and hydrolytic acidification zone, which is applied in the field of hydrolytic acidification and multi-metal catalyzed micro-electrolysis reactors, which can solve the problems of increased possibility of chain scission of macromolecular substances, low biodegradability of industrial wastewater, and limited treatment effect. Achieve the effect of improving water distribution effect, cheap cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

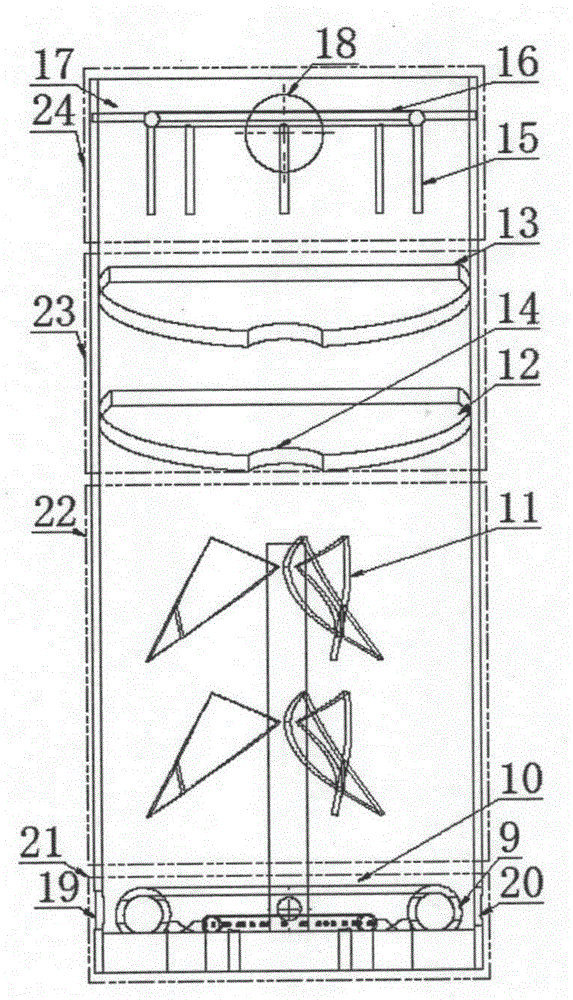

[0032] Such as figure 1 As shown, it is a schematic structural diagram of a micro-electrolytic catalytic enhanced hydrolytic acidification reactor. The micro-electrolytic catalytic enhanced hydrolytic acidification reactor includes a water and gas distribution area 21, a hydrolytic acidification area 22, and a two-phase separation area arranged in sequence from bottom to top. Zone 23 and Catalytic Enhanced Micro-electrolysis Zone 24.

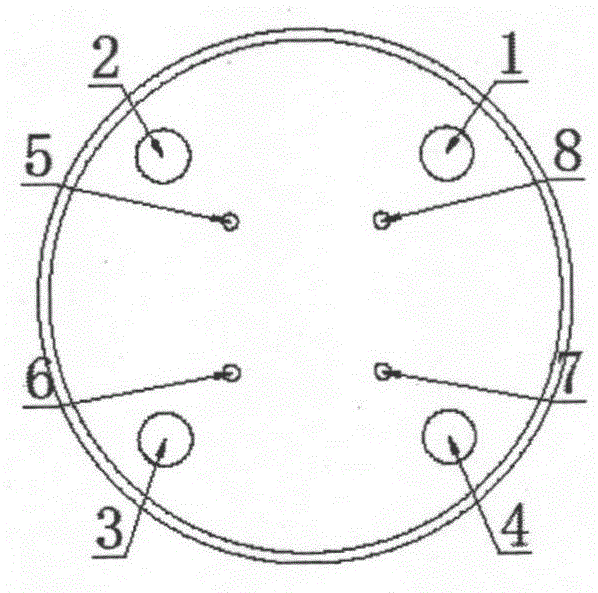

[0033] The water and air distribution area 21 includes a base plate and a lower column, the lower end of the lower column is connected to the base plate, the base plate is provided with water inlet holes and air intake holes, and the upper side of the base plate is provided with a porous cloth. Water dispenser 9 and porous air distributor 10, porous water distributor 9 and porous air distributor 10 are respectively connected to the water inlet hole and air inlet hole, the center of the bottom plate is provided with a rotator, and the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com