Cold storage system using water distribution modules

A technology of water distribution system and water module, which is applied in the field of air-conditioning cold storage, can solve the problems of large deformation, uneven temperature, and easy breakage of the phase change cold storage spherical shell, and achieve convenient and full contact, full contact, and convenient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

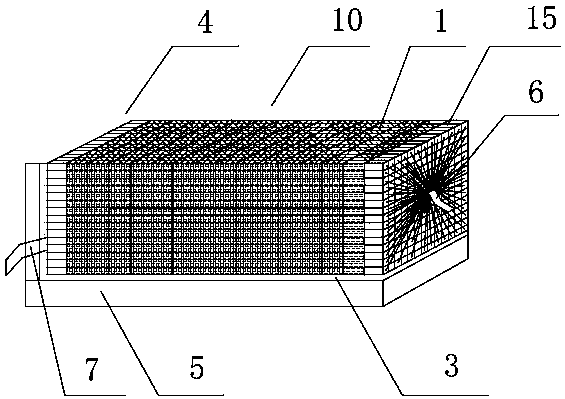

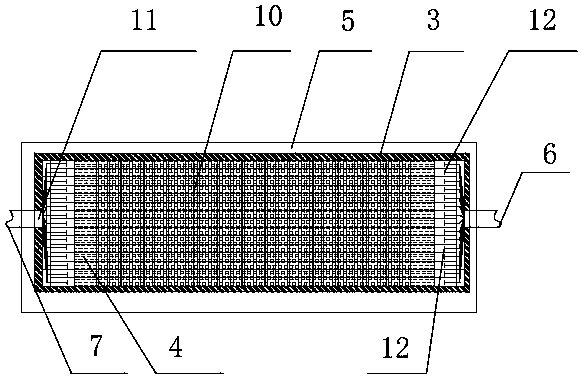

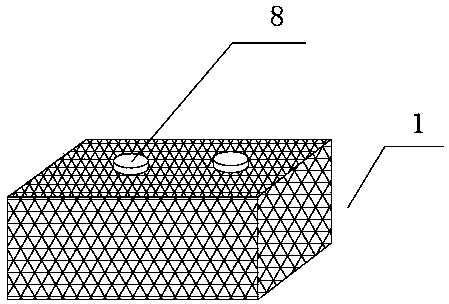

[0028] Embodiment 1, refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 :

[0029] A cold storage system using a water distribution module, including a cold storage body 10, the cold storage body 10 includes 3-200 square cold storage modules 1 neatly and closely arranged, the six sides of the cold storage module are all porous structures and at least one side is a detachable structure There are 20-200 phase change cold storage balls 2 in the square cold storage module 1, and the cold storage body 10 is covered with a waterproof membrane 3, and the waterproof membrane 3 is provided with a heat preservation board 5, and the two ends of the cold storage body 10 are covered with waterproof membranes. The water distribution system 4 is also provided on the inner side of the water distribution system. The water distribution system includes water distribution pipes and several water distribution modules 15; the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com