Efficient anti-pollution cation (anion) ion exchanger

A technology of ion exchangers and exchangers, applied in the field of ion exchangers, can solve problems such as no good limit function of branch pipes, easy damage of water distribution pipes and branch pipes, no good disassembly and assembly operations, etc., to achieve convenient management and avoid branch pipes Rotation, good operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

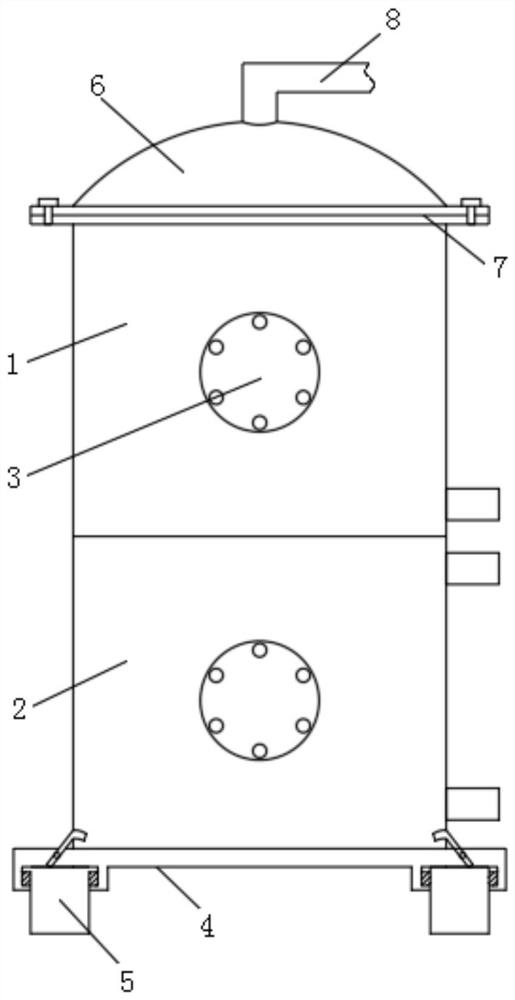

[0030] Embodiment 1: including the first exchanger 1 and the second exchanger 2, the first exchanger 1 is located at the upper end of the second exchanger 2, and the front ends of the first exchanger 1 and the second exchanger 2 are provided with through-hole covers Plate 3, the upper end surface of the first exchanger 1 is provided with a top cover 6, and the inner upper end of the first exchanger 1 is provided with a water distribution mechanism;

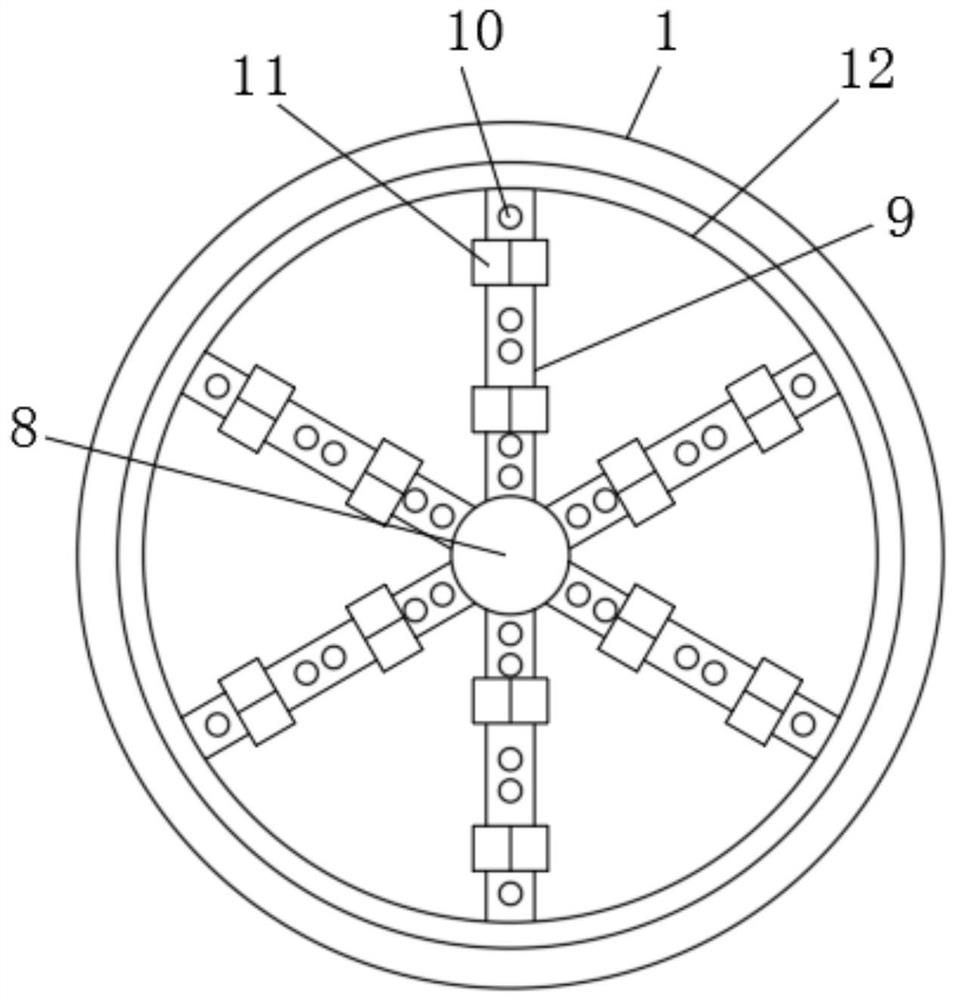

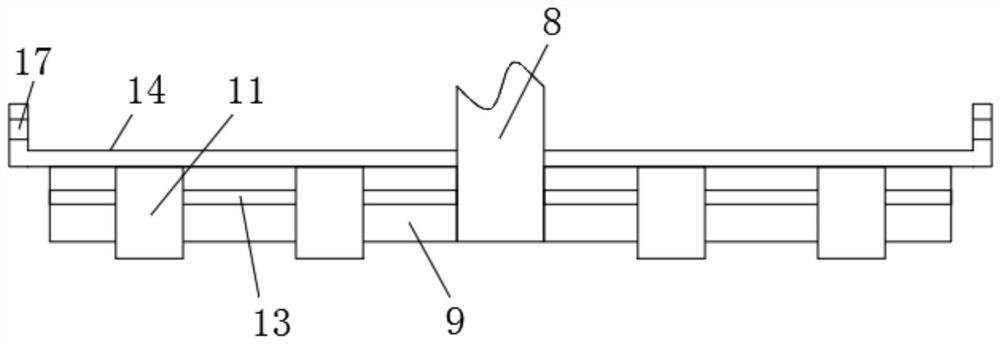

[0031] The water distribution mechanism includes a water distribution pipe 8, a fixed ring 12, a fixed rod 14, a branch pipe 9, a limit hoop 11, an elastic hinge 16 and a screw hole 17. The water distribution pipe 8 runs through the inside of the top cover 6 and extends to the first exchange Inside the device 1, there are several branch pipes 9, one end of several branch pipes 9 is connected to the water distribution pipe 8, the fixed rod 14 is fixedly connected between the fixed ring 12 and the water distribution pipe 8, and the l...

Embodiment 2

[0032] Embodiment 2: including the first exchanger 1 and the second exchanger 2, the first exchanger 1 is located at the upper end of the second exchanger 2, and the front ends of the first exchanger 1 and the second exchanger 2 are provided with through-hole covers Plate 3, the upper end surface of the first exchanger 1 is provided with a top cover 6;

[0033] A limiting mechanism is arranged between the branch pipe 9 and the limiting hoop 11. The limiting mechanism includes a limiting bar 13 and a limiting groove 15. The limiting groove 15 is set on the inner side of the limiting hoop 11, and the limiting bar 13 is fixedly connected. On both sides of the outer surface of the branch pipe 9 , the positions between the limiting strips 13 and the limiting grooves 15 correspond to each other.

Embodiment 3

[0034] Embodiment 3: including the first exchanger 1 and the second exchanger 2, the first exchanger 1 is located at the upper end of the second exchanger 2, and the front ends of the first exchanger 1 and the second exchanger 2 are provided with through-hole covers Plate 3, the upper end surface of the first exchanger 1 is provided with a top cover 6;

[0035] The lower end surface of the second exchanger 2 is provided with a base 4, and the corner positions of the lower end surface of the base 4 are all provided with supporting feet 5, and a connecting mechanism is provided between the base 4 and the second exchanger 2, and the connecting mechanism includes a buckle bar 18, Elastic hinge 2 19, spring 20 and slot, the slot is opened on the outer surface of the second exchanger 2 near the position of the leg 5, the buckle bar 18 is movably connected to the inside of the base 4 through the elastic hinge 2 19, and the spring 20 is sleeved on the The outside of the leg 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com