Column type water cap

A technology of water cap and column type, which is applied in the field of water cap of sewage treatment equipment, can solve the problems of narrow use range, poor water quality circulation, non-detachable, etc., and achieve improved operation efficiency, uniform water distribution effect, and convenient repeated use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

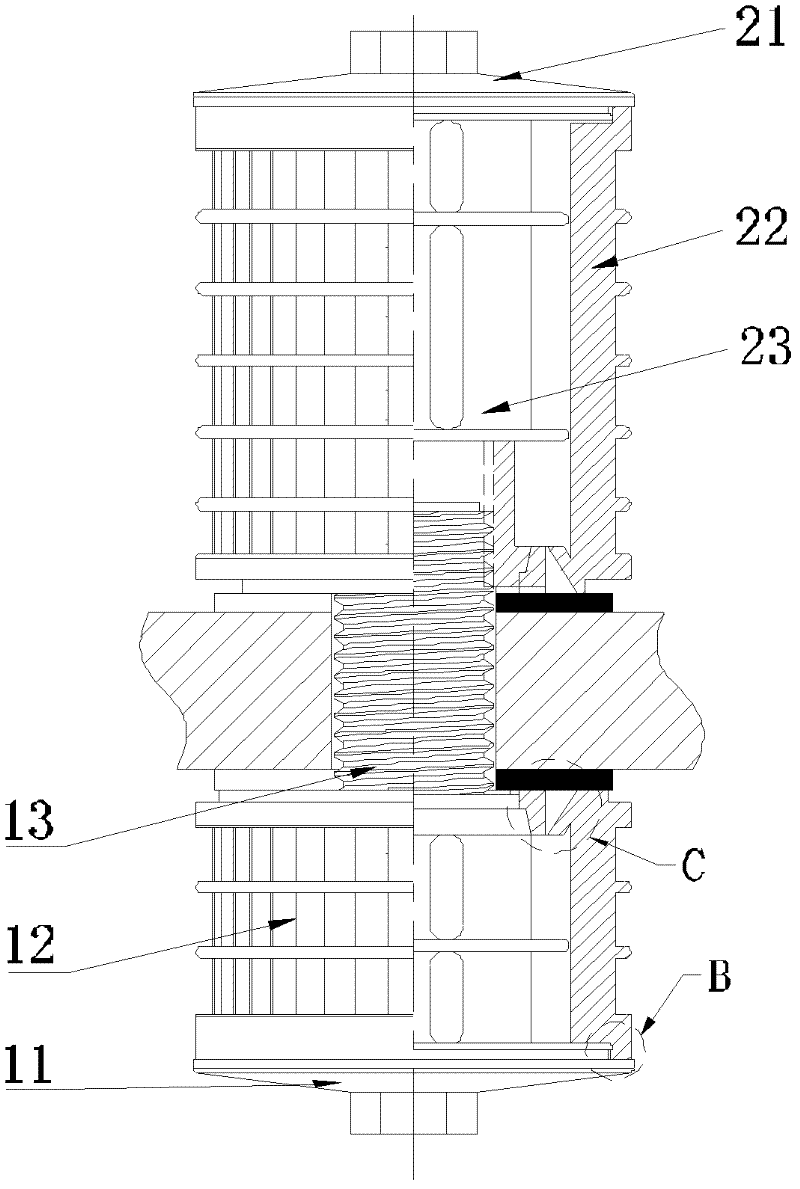

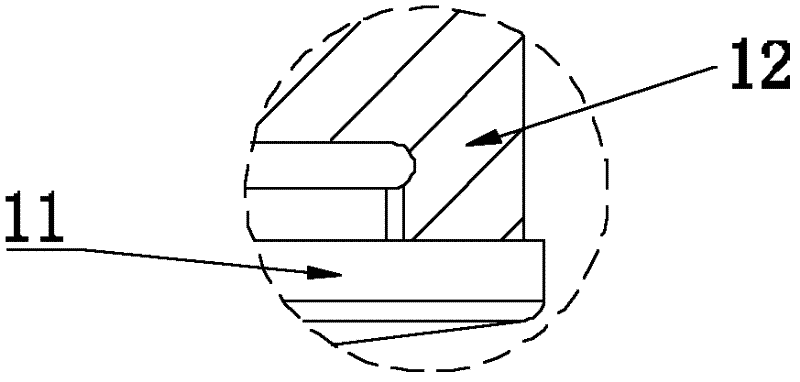

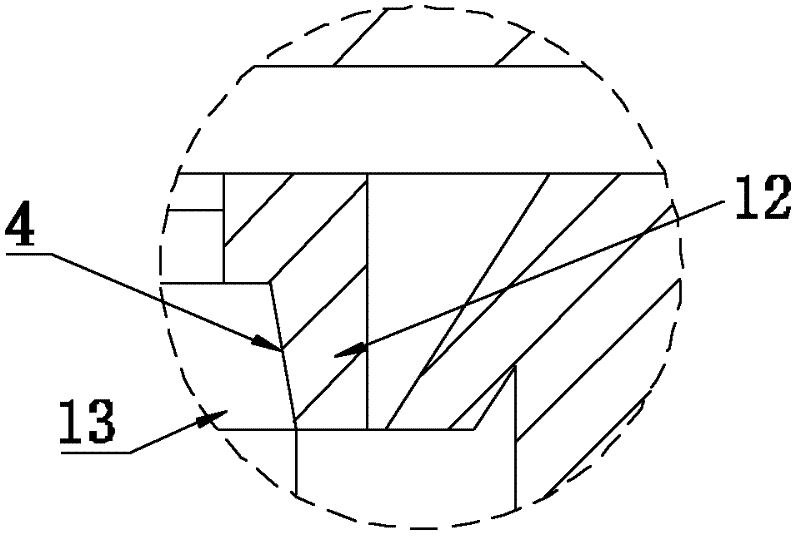

[0033] Such as figure 1 Shown is a specific embodiment of the present invention, which is a nested combination installation of two sets of water caps made of PVDF fluorine material that can be installed independently. One group includes a cap 11, a cap body 12 and a screw rod 13. The cap body 12 is a cylindrical overall structure with a ring-shaped protrusion on its outer surface. In order to enhance the overall design, vertical gaps are evenly distributed on the outer surface and a ring shape is evenly distributed on the bottom surface. Gap, the spacing of the annular gap is 0.25mm, and the vertical gap on the outer side of the cap body communicates with each other, the top of the screw rod 13 is fixedly connected with the cap 11, the upper part of the cap body 12 and the cap 11 are assembled and connected by snap buttons, the screw The bottom of 13 passes through the bottom of the cap body 12, and has at least a conical joint surface 4 with the bottom of the cap.

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com