Device and method for lignite and biomass microwave co-pyrolysis reaction

A biomass and co-pyrolysis technology, applied in the energy field, can solve the problems of insufficient combined utilization of lignite and biomass, and achieve the effects of easy large-scale production and application, convenient operation, and increased residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

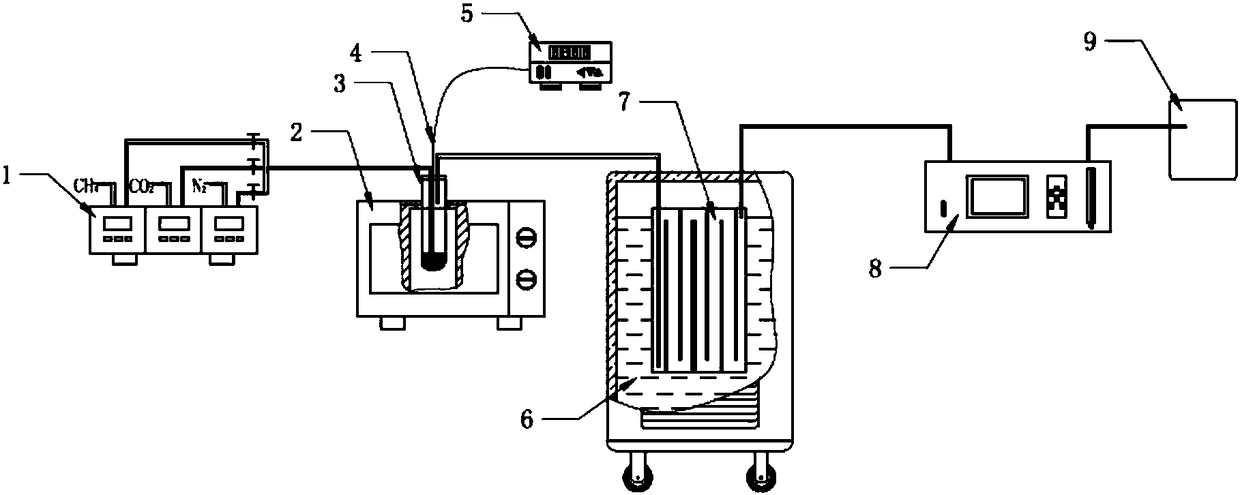

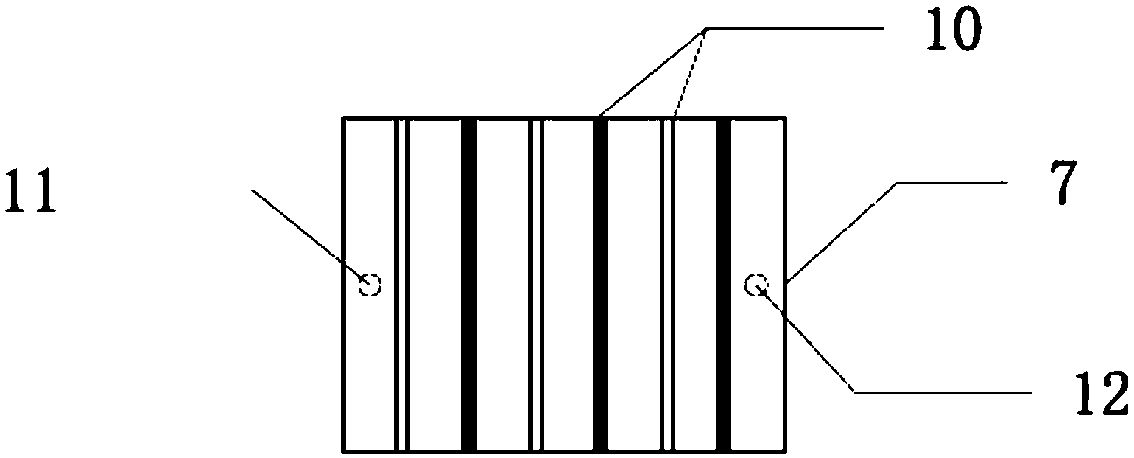

Method used

Image

Examples

Embodiment 1

[0044] After air-dried coal samples and corncobs were pulverized into <0.15mm powders, 10 g of the total mixed sample with a mass ratio of lignite to corncobs of 7:3 was prepared and transported to the quartz reactor, using microwaves as the heat source , under the microwave power of 700W, heating for 25min, the co-pyrolysis semi-coke product remains at the bottom of the quartz reactor, the oil-gas mixture is condensed by a circulating cooling device, and the pyrolysis tar and pyrolysis gas are separated, wherein the pyrolysis gas continues to Real-time analysis by online gas analyzer.

Embodiment 2

[0046] After air-dried coal samples and corncobs were pulverized to <0.15mm powders, 10 g of the total mixed sample with a mass ratio of lignite to corncobs of 8:2 was prepared and transported to a quartz reactor, using microwaves as a heat source. The microwave power is 460W, heating for 25min, the co-pyrolysis semi-coke product stays at the bottom of the quartz reactor, the oil-gas mixture is condensed by the circulating cooling device, and the pyrolysis tar and pyrolysis gas are separated, and the pyrolysis gas continues to pass through the online gas analyzer Perform real-time analysis.

Embodiment 3

[0048] After air-dried coal samples and corncobs were pulverized to <0.15mm powders, 10 g of the total mixed sample with a mass ratio of lignite to corncobs of 8:2 was prepared and transported to a quartz reactor, using microwaves as a heat source. The microwave power is 700W, heating for 15min, the co-pyrolysis semi-coke product stays at the bottom of the quartz reactor, the oil-gas mixture is condensed by the circulating cooling device, and the pyrolysis tar and pyrolysis gas are separated, and the pyrolysis gas continues to pass through the online gas analyzer Perform real-time analysis.

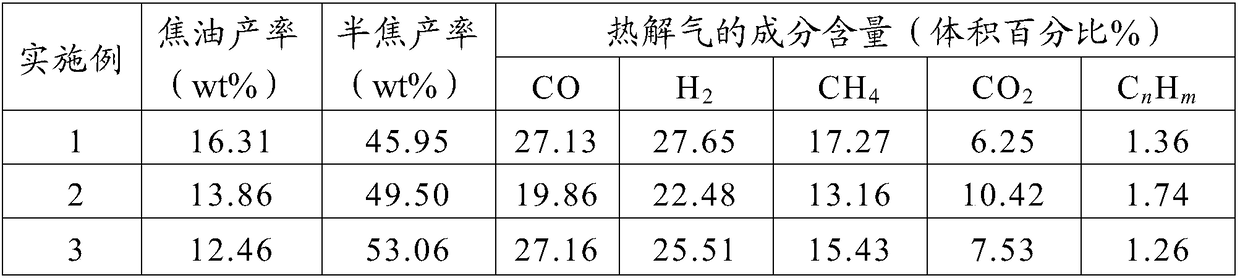

[0049] The result after embodiment 1, embodiment 2, embodiment 3 co-pyrolysis reaction is as shown in table 1:

[0050] Table 1

[0051]

[0052] It can be seen from Table 1 that the yield of tar products from microwave co-pyrolysis of lignite and corncobs is 10-20%, the yield of semi-coke products is about 50%, and the CO and H in the pyrolysis gas 2 and CH 4 The sum of the average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com