Methods and apparatus for liquefaction of organic solids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

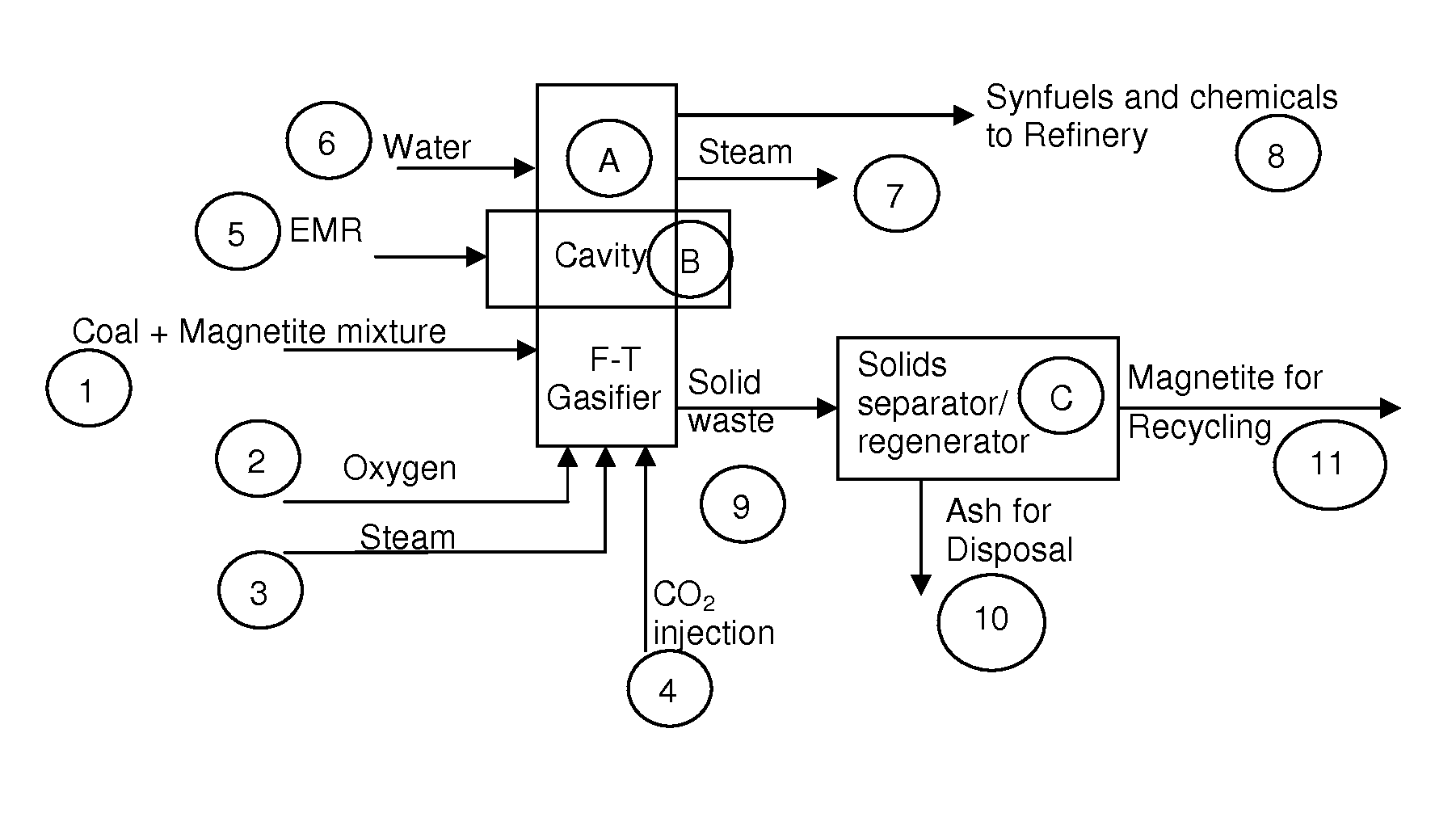

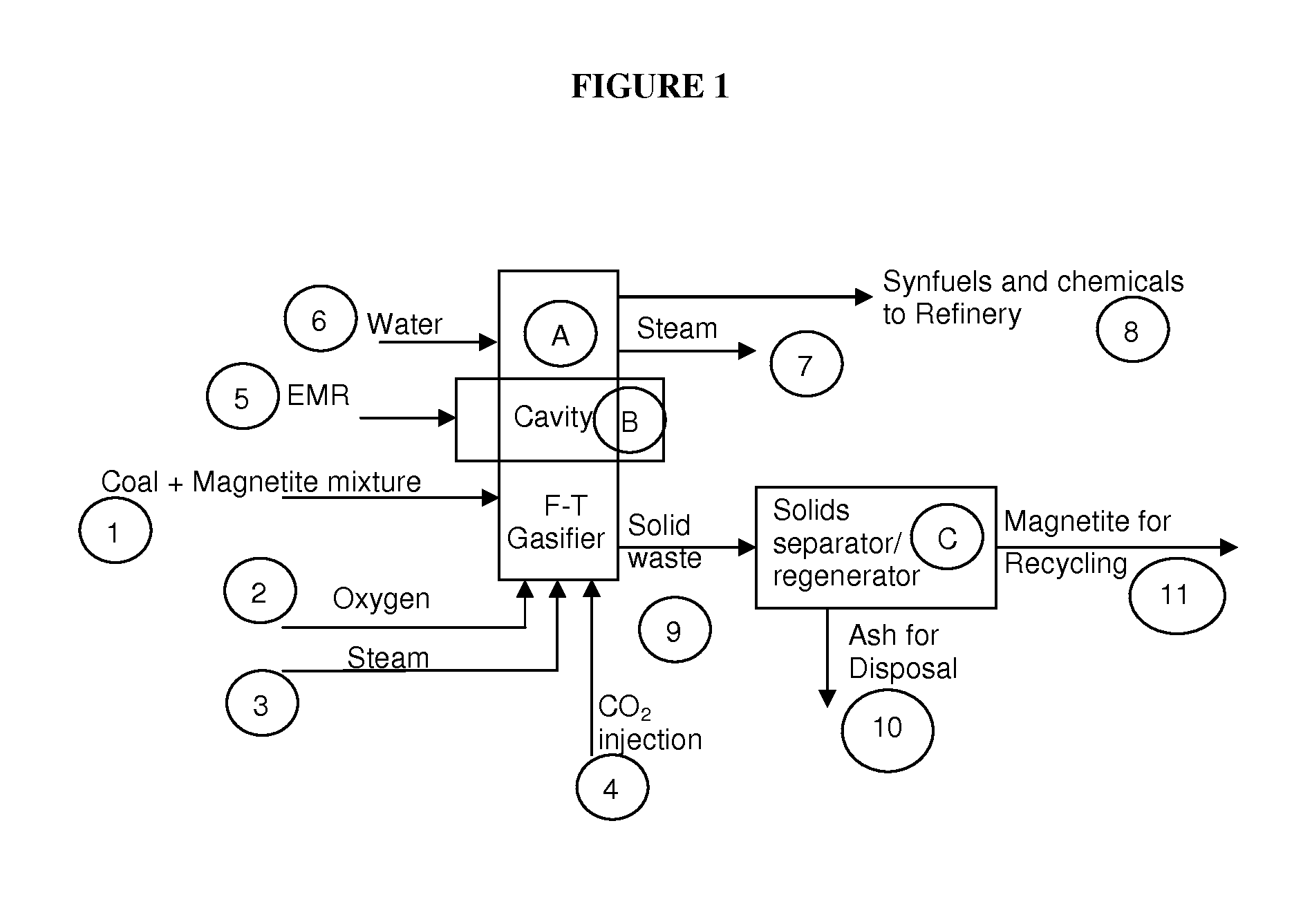

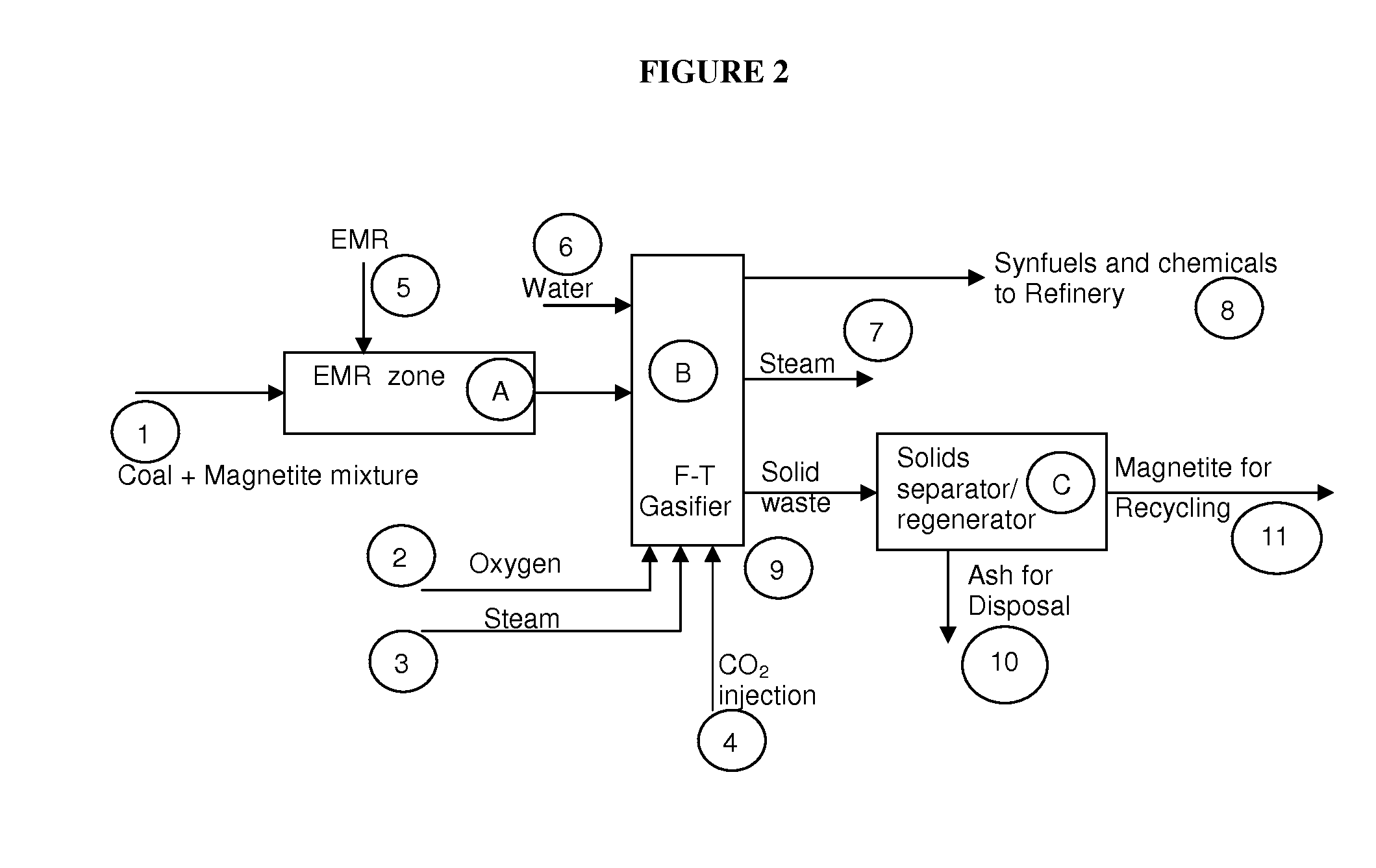

[0025]The present inventor has discovered an efficient single step process which incorporates electromagnetic radiation (EMR) energy for converting solid organic minerals, such as coal and biomass, into liquid or gas products. The single step EMR process offers a cleaner, more attractive and cost effective approach to producing synthetic fuels. The processes described herein are also referred to as “F-T Gasification Processes.”

[0026]Thus, in one aspect, the present invention relates to an improved process for the conversion of organic matter, such as coal, biomass, or other organic solids to liquid or gas products. Coal liquefaction has its roots in Germany in the early 1900s. U.S. Pat. No. 1,746,464, issued to Franz Fischer and Hans Tropsch in 1930, describes a process for converting carbon monoxide and hydrogen to hydrocarbons in the presence of a catalyst. This process subsequently became known as the F-T Process. According to the '464 patent, temperature plays a decisive role in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com