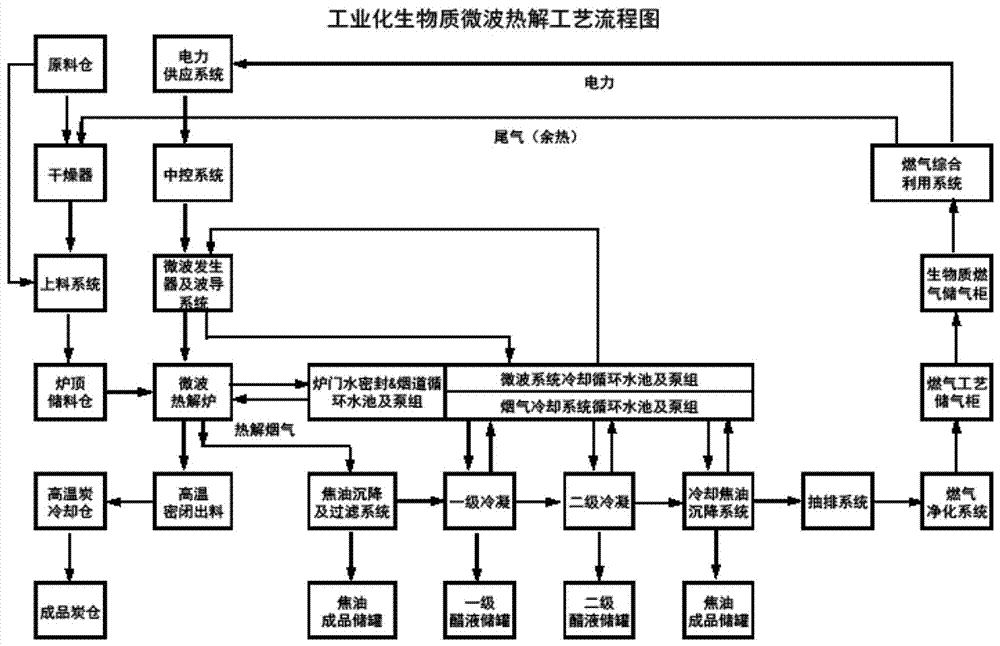

Production process and technology for high-power microwave pyrolysis of biomass

A production process and biomass technology, applied in the direction of biofuel, tar processing, petroleum industry, etc., can solve problems such as metal salts or metal oxide residues, pollution, etc., to improve utilization efficiency and reliable production process and technology, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Put 3000kg of wood chips or wood blocks with a particle size of 10-200mm and a moisture content of 5% into the microwave pyrolysis furnace cavity. After closing the furnace door, start the exhaust system to keep the pressure of the pyrolysis furnace cavity at -350Pa. The total power of 240KW starts to feed microwave energy continuously for 5 minutes until the total power of microwave reaches 400KW;

[0022] (2) Keep the total power of the microwave at 400KW, and continue to feed microwave energy for 30 minutes. After the average temperature of the pyrolysis furnace chamber rises to 120°C, the pressure and temperature of the pyrolysis furnace chamber begin to increase, and the smoke in the microwave pyrolysis chamber The output of carbon monoxide, carbon dioxide and alkane gas is not detected in the gas exhaust pipe, control and adjust the exhaust system, keep the pressure of the pyrolysis furnace chamber at -500Pa, and remove the water vapor in the pyrolysis furnace ...

Embodiment 2

[0033] (1) Put 3150kg of bamboo or bamboo pieces with a particle size of 100-200mm and a moisture content of 12.86% into the microwave pyrolysis furnace cavity. After closing the furnace door, start the exhaust system to keep the pressure of the pyrolysis furnace cavity at -350Pa. The total power of 240KW starts to feed microwave energy continuously for 3 minutes until the total power of microwave reaches 400KW;

[0034] (2) Keep the total power of the microwave at 400KW, and continue to feed microwave energy for 30 minutes. After the average temperature of the pyrolysis furnace chamber rises to 120°C, the pressure and temperature of the pyrolysis furnace chamber begin to increase, and the smoke in the microwave pyrolysis chamber The output of carbon monoxide, carbon dioxide and alkane gas is not detected in the gas exhaust pipe, control and adjust the exhaust system, keep the pressure of the pyrolysis furnace chamber at -500Pa, and remove the water vapor in the pyrolysis furna...

Embodiment 3

[0045] (1) Put 2000kg of bagasse with a particle size of 1-30mm and a water content of 48% into the microwave pyrolysis furnace cavity. After closing the furnace door, start the exhaust system to keep the pressure of the pyrolysis furnace cavity at -350Pa, and use a total microwave power of 240KW Start feeding microwave energy continuously for 1 minute until the total microwave power reaches 400KW;

[0046] (2) Keep the total power of the microwave at 400KW, and continue to feed microwave energy for 30 minutes. After the average temperature of the pyrolysis furnace chamber rises to 120°C, the pressure and temperature of the pyrolysis furnace chamber begin to increase, and the smoke in the microwave pyrolysis chamber The output of carbon monoxide, carbon dioxide and alkane gas is not detected in the gas exhaust pipe, control and adjust the exhaust system, keep the pressure of the pyrolysis furnace chamber at -500Pa, and remove the water vapor in the pyrolysis furnace chamber;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com