Low temperature dry distillation coke oven hot-water circulation utilizing system

A technology of hot water circulation and coke oven, which is applied in coke oven heating, coke oven, petroleum industry, etc., can solve the problems of high pressure, large investment, high operating cost, etc., and achieves favorable storage and discharge, safe and reliable operation, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

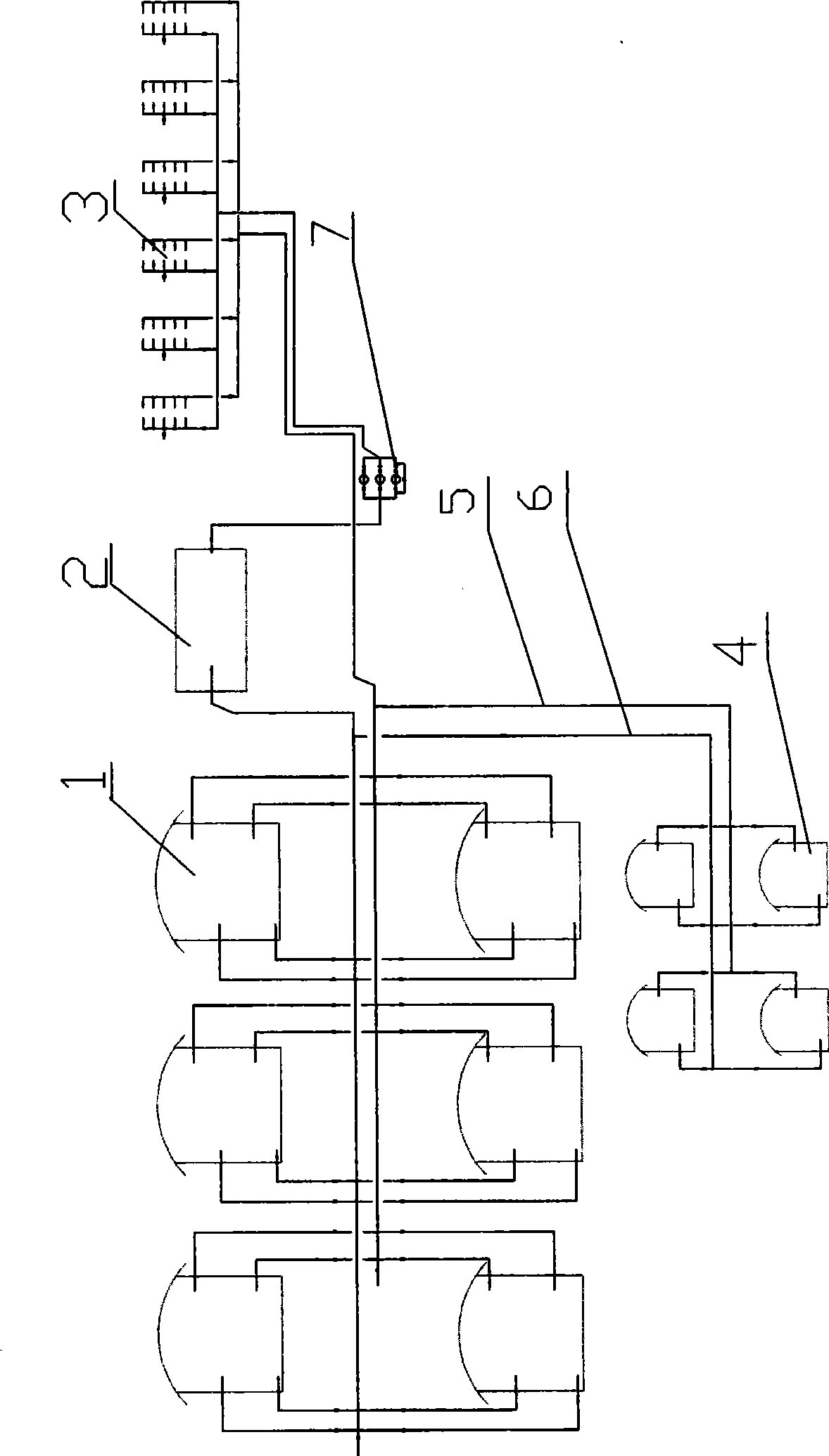

[0013] As shown in the accompanying drawings, the present invention mainly arranges a cooling jacket 3 with a sandwich structure under the coke oven, and the cavity in the middle of the cooling jacket 3 communicates with the coke oven and the coke guide port. The water outlet of the cooling jacket 3 is connected with the water delivery pipe 5, and the other end of the water delivery pipe 5 is connected with the heating pipeline of the dehydration tank 4 and the tar tank 1 again. The return pipe 6 from the dehydration tank 4 and the tar tank 1 is connected to the circulating water tank 2, and the output pipe of the circulating water tank 2 is communicated with the water inlet of the cooling jacket 3 through a circulating water pump 7 to form a closed loop system.

[0014] In actual operation, the circulating water pump 7 sends the water in the circulating water tank 2 to the cooling jacket 3, and the high-temperature semi-coke falling from the coke oven will exchange heat with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com