60kg microwave coking trial furnace and coking method

A test furnace and microwave technology, which is used in coke ovens, coke oven heating, special forms of dry distillation, etc., can solve the problems of easy damage to electric heating tubes, reduce heating efficiency, and prolong heating time, saving coking time and heating. High efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

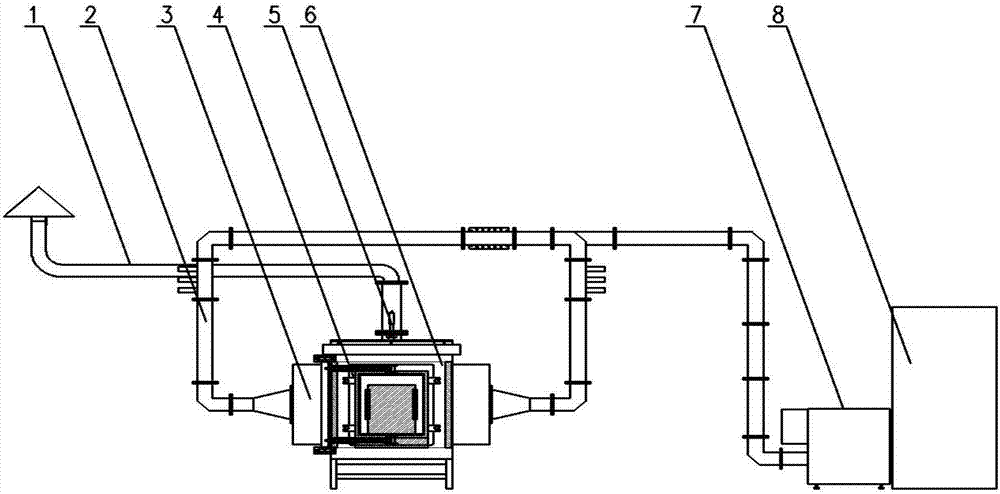

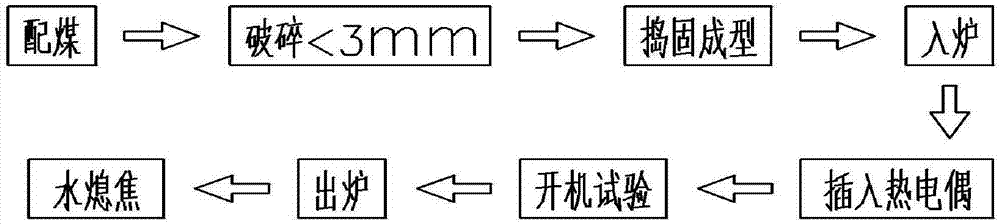

[0046] Such as figure 2 Shown, a kind of microwave coking test method, it comprises the following steps:

[0047] Step 1. Weigh 60 kg of coking coal particles, place them in a briquette mold, and press them into briquettes;

[0048] Step 2. Put the coal cake and the coal cake mold together into the microwave test furnace. After adjusting the position, take out the coal cake mold, and insert the infrared contact sensor from the top of the cavity plate of the microwave test furnace into the furnace chamber of the microwave test furnace , adjust the distance between the infrared contact sensor and the coal cake to be 3cm;

[0049] Step 3, closing the furnace doors on both sides of the microwave energy action cavity 4;

[0050] Step 4,

[0051] ① Check whether the microwave test furnace is well grounded and whether the circuit is well connected;

[0052] ②Start the power supply of the microwave energy generator 7 on the power control cabinet 8, and observe whether the door sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com