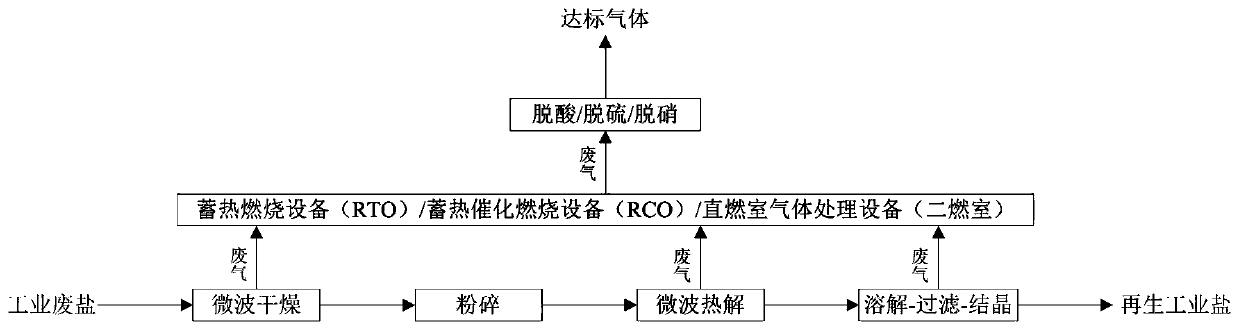

Treatment process of industrial waste salt

A technology for treating process and industrial waste salt, applied in solid waste removal, chemical instruments and methods, transportation and packaging, etc., can solve the problem of low treatment efficiency, achieve high treatment efficiency, good prospects for industrialization promotion, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The industrial waste sodium chloride (hereinafter referred to as raw material) provided by the pesticide factory has a yellowish-brown color and a particle size of 2mm. The main components include: about 70wt% sodium chloride, and the rest are pesticide residue organic matter, inorganic matter and water.

[0048] Put 1000g of raw material into a microwave oven to dry, set the microwave power to 1500W, heat the raw material to 120°C, keep it for 10 minutes, turn off the microwave power supply, and take out the raw material when the temperature of the raw material drops to room temperature, and the raw material turns grayish yellow. At this time, the weight of the raw material is 925g, weight loss of 7.5wt% through drying raw material.

[0049] The dried raw material is crushed to less than 0.1 mm, and then added to a microwave oven for cracking. Set the power of the microwave power supply to 1500W, heat to 480°C, and keep it warm for 30 minutes. During the pyrolysis proc...

Embodiment 2

[0052] The industrial waste sodium chloride (hereinafter referred to as raw material) that pharmaceutical factory provides, color is yellow, and particle size is 1.5mm, main component comprises: sodium chloride about 85wt%, all the other are residual organic matter, inorganic matter and water.

[0053] Put 1000g of raw material into a microwave oven to dry, set the microwave power to 1500W, heat the raw material to 160°C, keep it for 20 minutes, turn off the microwave power supply, and take out the raw material when the temperature of the raw material drops to room temperature, and the raw material turns grayish yellow. At this time, the weight of the raw material is 862g, a weight loss of 13.8wt% after drying the raw material.

[0054] The dried raw material is crushed to less than 0.1 mm, and then added to a microwave oven for cracking. Set the power of the microwave power supply to 1500W, heat to 450°C, and keep it warm for 20 minutes. During the pyrolysis process, the raw ...

Embodiment 3

[0057] Industrial waste sodium chloride (hereinafter referred to as raw material) provided by a pesticide factory has a brownish yellow color and a particle size of 0.5mm. The main components include: about 85wt% sodium chloride, and the rest are residual organic matter, inorganic matter, water and other impurities .

[0058] Put 1000g of raw material into a microwave oven to dry, set the microwave power to 1500W, heat the raw material to 200°C, keep it for 10 minutes, turn off the microwave power supply, and take out the raw material when the temperature of the raw material drops to room temperature, and the raw material turns light yellow. At this time, the weight of the raw material is 816g, weight loss of 18.4wt% through drying raw material.

[0059] The dried raw material is crushed to less than 0.1 mm, and then added to a microwave oven for cracking. Set the power of the microwave power supply to 1500W, heat to 470°C, and keep it warm for 30 minutes. During the pyrolysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com