Industrial waste salt slag innocent treatment method

A technology for harmless treatment and industrial waste salt, which is applied in the fields of harmless treatment of industrial waste salt residue, harmless disposal of industrial waste salt residue and resource utilization, which can solve the problem of occupying large land, secondary environmental hazards and high cost. and other issues to achieve the effect of promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

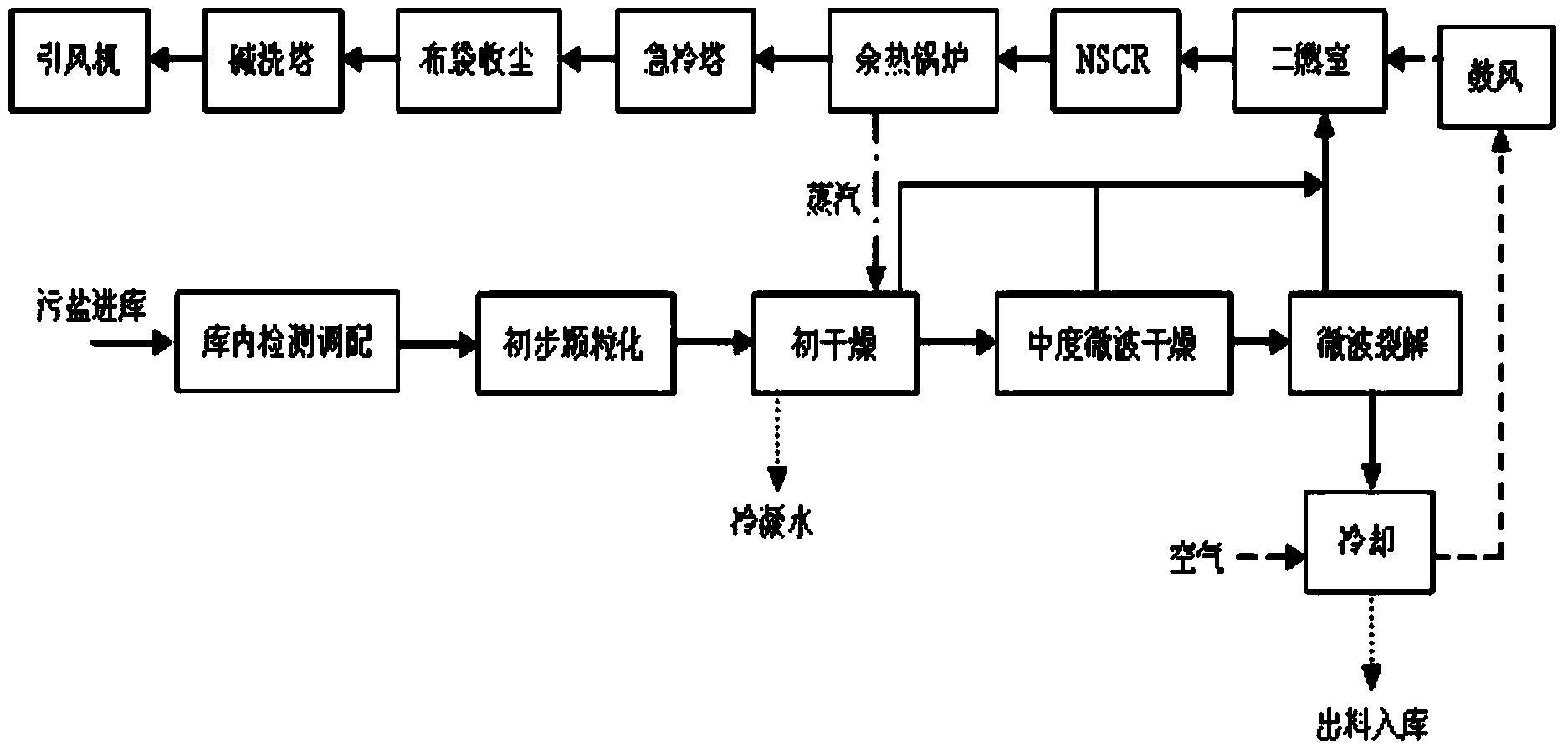

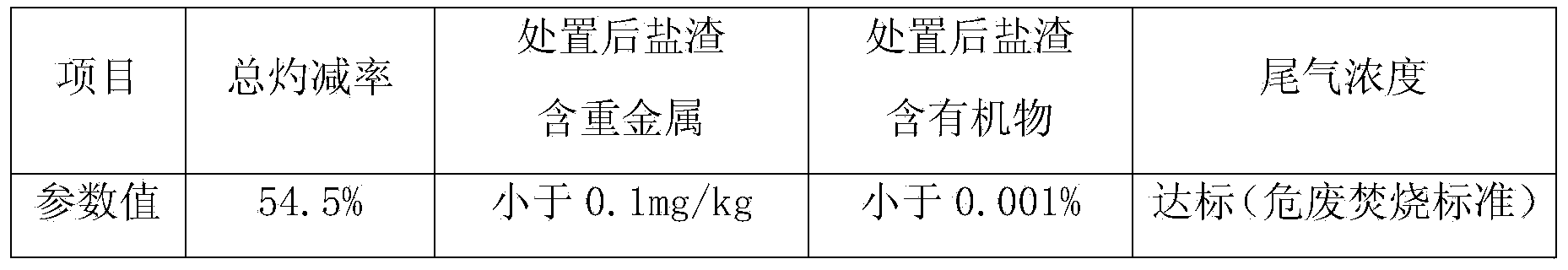

[0054] Embodiment: First, make a judgment on the source of the waste salt slag (the place of origin is firstly classified), and carry out batch detection in the warehouse, and mix the ingredients according to the source and category, and strive to mix the materials evenly. First, coarse granulation, then initial drying to remove most of the free water, and then moderate microwave drying under reduced pressure (vacuum), trying to remove crystal water and gasify part of the organic matter, after moderate microwave drying, then anaerobic Microwave cracking unit, control the temperature at 450-500 degrees, and crack for more than 100 minutes in a nitrogen-filled environment. Organic matter is cracked into small molecules and then gasified, organic salts are decomposed and gasified, and ammonium salts are decomposed. The waste salt after cracking is completely recovered. It is harmless and stored in the warehouse after air cooling. After passing the test, it is sold for reuse. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com