Catalyst for waste plastic microwave pyrolysis and preparation method thereof

A technology for cracking catalysts and waste plastics, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of liquid hydrocarbon mixtures. Clear, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Catalyst preparation:

[0041] (1) Mix 50.0 g of 10-mesh activated carbon with 49.9 g of 10-mesh γ-Al 2 o 3 Add it into the mixer, and keep stirring for 1 h to obtain material 1;

[0042] (2) 0.1 g of potassium acetate is dissolved in 10 g of water to obtain solution 1;

[0043] (3) During the stirring process, spray the solution 1 obtained in step (2) onto the material 1 obtained in step (1) to obtain material 2;

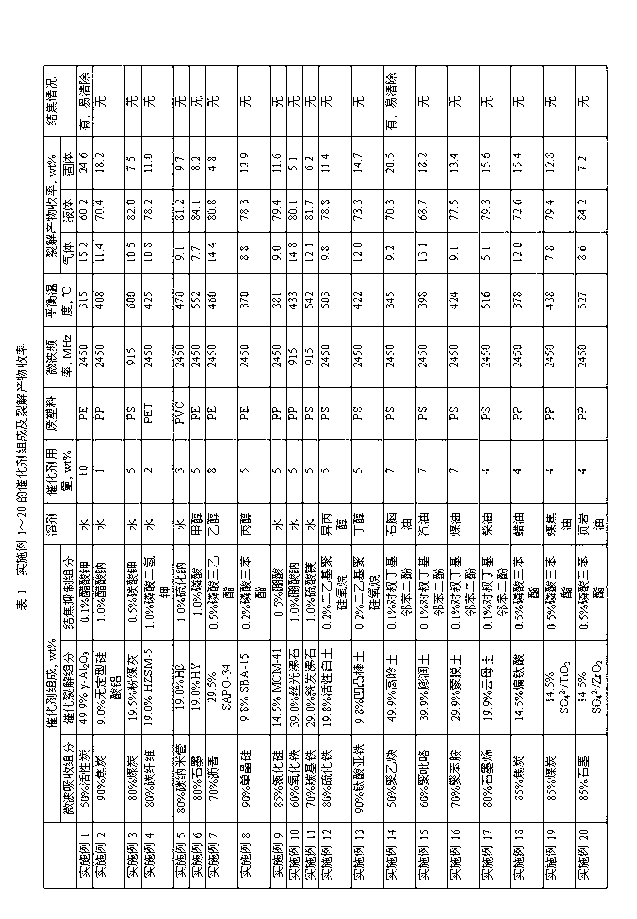

[0044] (4) Material 2 was vacuum-dried at 100 °C for 2 h, and the microwave cracking catalyst was obtained after removing water. The composition of the catalyst is shown in Table 1.

[0045] Microwave cracking reaction:

[0046] Weigh 10.0 g of the catalyst of this embodiment and 100 g of waste polyethylene (PE), mix them uniformly and carry out microwave cracking reaction, the frequency of microwave is 2450 MHz, the equilibrium temperature that can be reached in the reaction process is 315 ° C, the microwave cracking product The yield and cokin...

Embodiment 2

[0048] Catalyst preparation:

[0049] (1) Add 90.0 g of 800-mesh coke and 9.0 g of 800-mesh amorphous aluminum silicate into the mixer, and keep stirring for 1 h to obtain material 1;

[0050] (2) 1.0 g of sodium acetate is dissolved in 10 g of water to obtain solution 1;

[0051] (3) During the stirring process, spray the solution 1 obtained in step (2) onto the material 1 obtained in step (1) to obtain material 2;

[0052] (4) Material 2 was vacuum-dried at 100 °C for 2 h, and the microwave cracking catalyst was obtained after removing water. The composition of the catalyst is shown in Table 1.

[0053] Microwave cracking reaction:

[0054] Weigh 1.0 g of the catalyst of this embodiment and 100 g of waste polypropylene (PP), mix them evenly, and carry out microwave cracking reaction. The frequency of microwave is 2450 MHz, and the equilibrium temperature that can be achieved in the reaction process is 408 ° C. The microwave cracking product The yield and coking si...

Embodiment 3

[0056] Catalyst preparation:

[0057] (1) Add 80.0 g of 500-mesh coal and 19.5 g of 500-mesh fly ash into the mixer, and keep stirring for 1 hour to obtain material 1;

[0058] (2) 0.5 g of potassium carbonate is dissolved in 10 g of water to obtain solution 1;

[0059] (3) During the stirring process, spray the solution 1 obtained in step (2) onto the material 1 obtained in step (1) to obtain material 2;

[0060] (4) Material 2 was vacuum-dried at 100 °C for 2 h, and the microwave cracking catalyst was obtained after removing water. The composition of the catalyst is shown in Table 1.

[0061] Microwave cracking reaction:

[0062] Weigh 5.0 g of the catalyst of this embodiment and 100 g of waste polystyrene (PS), mix them uniformly, and carry out microwave cracking reaction. The frequency of microwave is 915 MHz, and the equilibrium temperature that can be achieved in the reaction process is 600 ° C. The microwave cracking product The yield and coking situation are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com