Method and device for pyrolysising bio-matter using microwave

A biomass and microwave technology, applied in the direction of combustion methods, lighting and heating equipment, combustion types, etc., can solve problems such as difficult fineness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

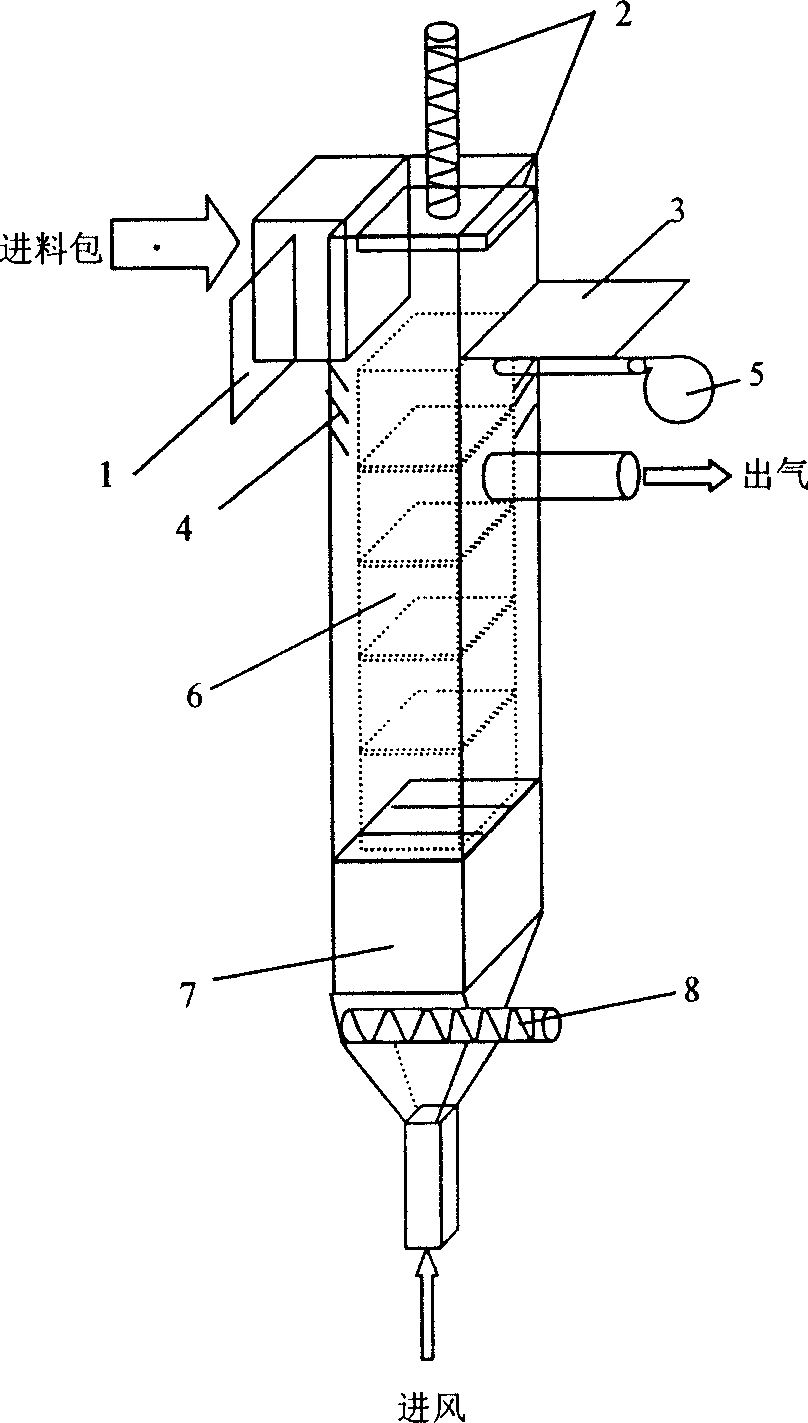

[0014] Example: The microwave pyrolysis biomass device taking the vertical kiln layout as an example is shown in the attached figure, and its main components include 1. Cut-off door A; 2. Screw pressing device; 3. Cut-off door B; 4. Spring leaf ;5, air leakage induced draft fan; 6, microwave pyrolysis chamber; 7, charcoal combustion chamber; 8, ash auger.

[0015] The working process of the device is as follows: when feeding, the cut-off door B3 is closed, the cut-off door A1 is opened, and the bundle of biomass or material bag is placed under the screw pressing device 2. At this time, the cut-off door A1 is closed, the cut-off door B3 is opened, and the bundle of biomass is placed under the screw pressing device 2. Or the material bag moves down under the promotion of gravity and the screw pressing device 2, and when it moves down and crosses the position of the cut-off door B3, the screw press device 2 resets, the cut-off door B3 is closed, and then repeats the above feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com