High-selectivity catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and preparation method thereof

A high-selectivity, catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems that precious metals cannot meet industrial production, achieve broad industrial application prospects, shorten pyrolysis process, avoid Paradoxical effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

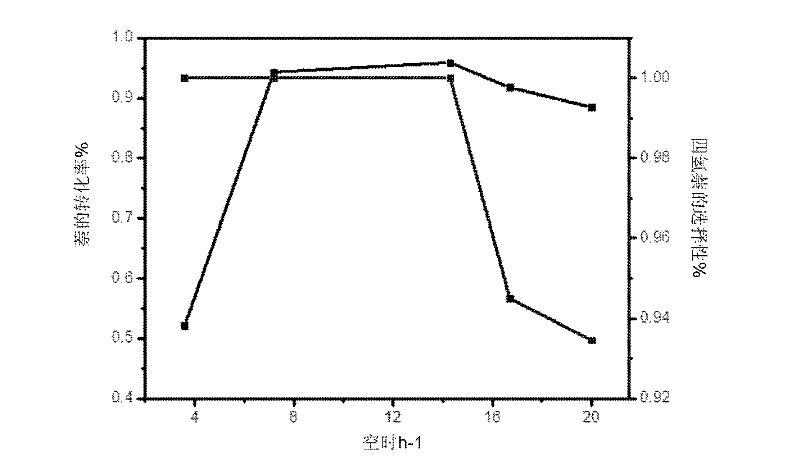

[0020] The preparation of embodiment 1 activated carbon supported molybdenum carbide catalytic material

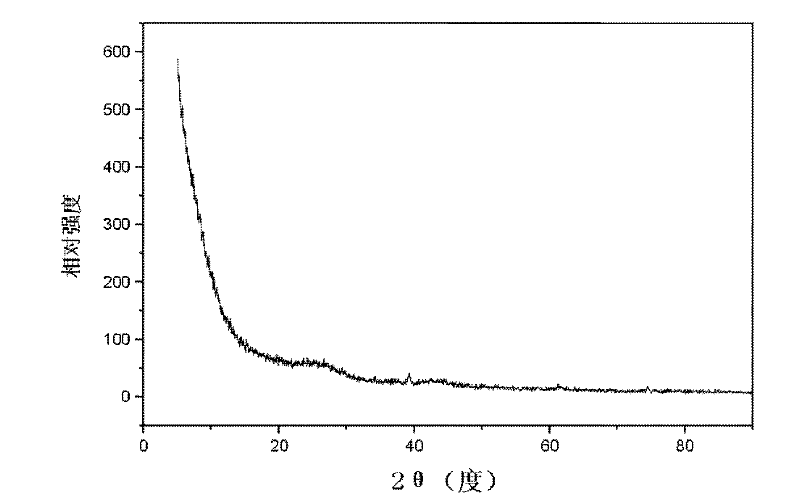

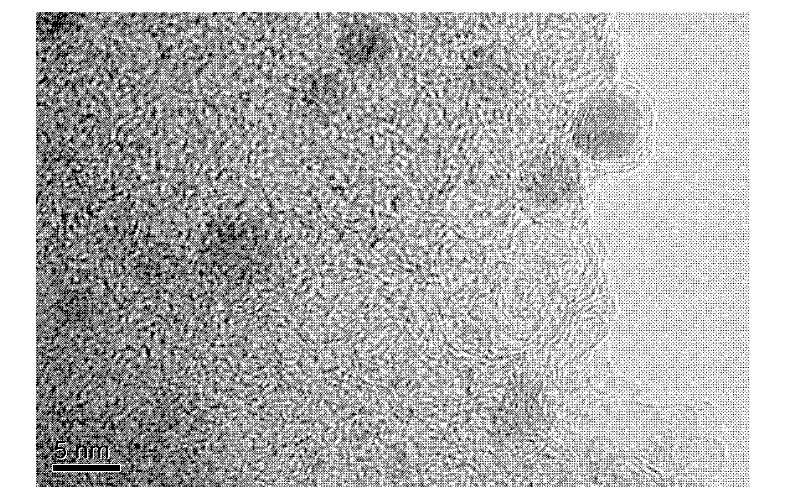

[0021] A certain amount of molybdenum-hexamethylenetetramine complex was added into 1 milliliter of ammonia water with a concentration of 15%. After fully dissolving, 0.1 g of activated carbon was weighed and added to the solution, and the solvent was naturally evaporated at room temperature. °C for 3 hours to obtain the precursor of molybdenum carbide. Molybdenum carbide precursors with different molybdenum loadings can be prepared by changing the amount of molybdenum-hexamethylenetetramine complex added. Place the precursor in a microwave reactor, blow it with argon for 2 hours, turn on the microwave at 800W and heat it for 30min under an argon atmosphere. After the sample is cooled, it is identified as Mo by X-ray powder diffraction. 2 c.

Embodiment 2

[0022] The preparation of the molybdenum carbide catalytic material of embodiment 2SBA-15 loading nickel modification

[0023] A certain amount of molybdenum-hexamethylenetetramine complex is added to 1 ml of 15% ammonia water, and 1 ml of 15% ammonia water is added. After fully dissolving, add 0.1 g of activated carbon into the solution, evaporate the solvent naturally at room temperature, and dry in a vacuum oven at 80°C for 3 hours to obtain a nickel-modified molybdenum carbide precursor. Nickel-modified molybdenum carbide precursors with different loadings of molybdenum and nickel can be prepared by changing the addition amount of molybdenum-hexamethylenetetramine complex and nickel nitrate hexahydrate. Since the molybdenum carbide precursor modified by SBA-15 loaded with nickel does not absorb microwaves and cannot heat itself under the action of microwaves, 0.05g of zirconia is mixed with the precursor and placed in a microwave reactor (zirconia is used to absorb microwa...

Embodiment 3 2

[0024] The preparation of the molybdenum carbide catalytic material of embodiment 3 silica loaded cobalt modification

[0025] A certain amount of molybdenum-hexamethylenetetramine complex is added to 1 ml of 15% ammonia water, and 1 ml of 15% ammonia water is added. After being fully dissolved, 0.1 g of silicon dioxide was weighed and added to the solution, the solvent was naturally evaporated at room temperature, and dried in a vacuum oven at 80°C for 3 hours to obtain a cobalt-modified molybdenum carbide precursor. Cobalt-modified molybdenum carbide precursors with different loadings of molybdenum and cobalt can be prepared by changing the addition amount of molybdenum-hexamethylenetetramine complex and cobalt chloride hexahydrate. Since the silica-supported cobalt-modified molybdenum carbide precursor does not absorb microwaves and cannot heat itself under the action of microwaves, 0.05g of zirconia is mixed with the precursor and placed in a microwave reactor (zirconia is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com