Method and device for recovering precious metals from precious metal electronic scraps

一种电子废料、贵金属的技术,应用在塑料回收、机械材料回收、回收利用技术等方向,能够解决不利贵金属分离、成分复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

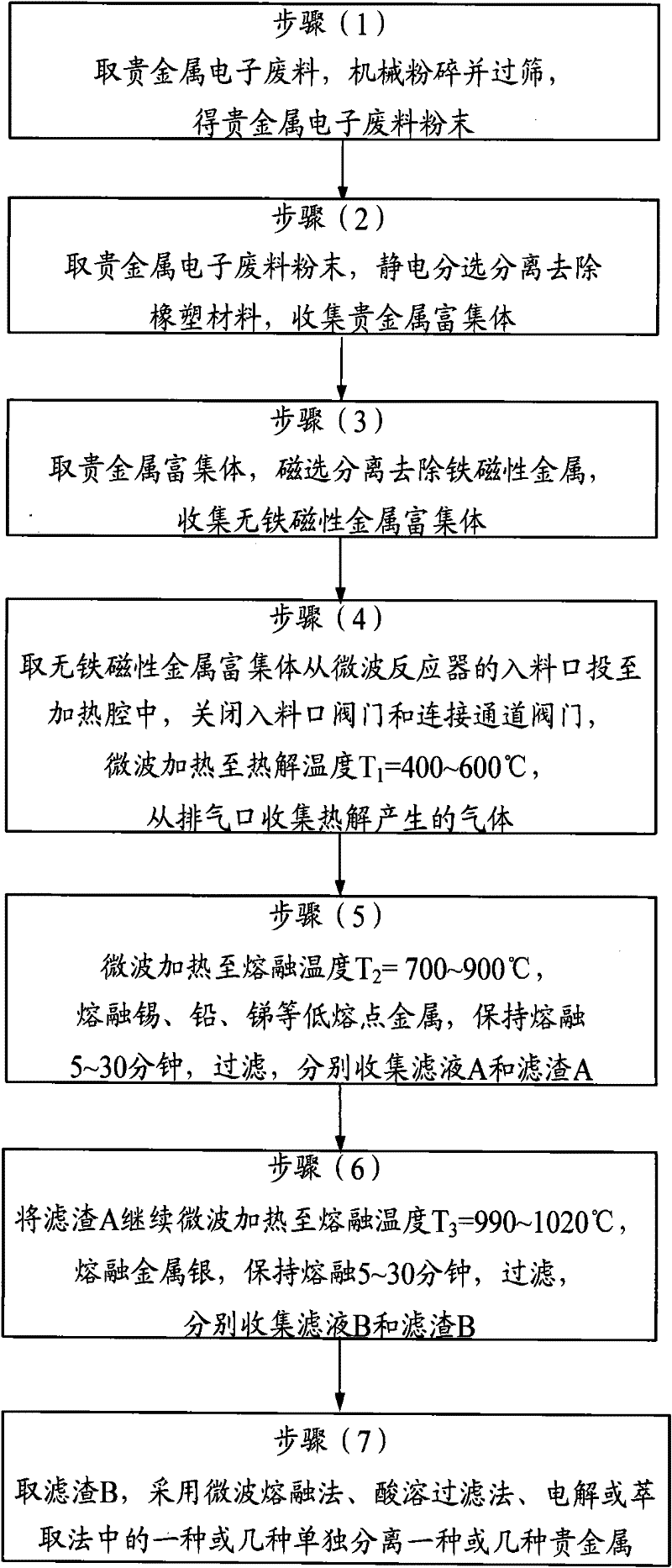

[0065] Embodiment one (the process flow diagram A of the present embodiment is as figure 2 shown)

[0066] Raw materials: waste computer boards (1 ton)

[0067] plastic

iron

lead

silver

gold

content / kg)

272

130

41

29

20

18

10

9

0.45

0.05

0.02

Melting point / ℃

500

1083

/

327

231.9

1455

630.5

960

1063

1772

1552

[0068] process:

[0069] step 1)

[0070] After the discarded circuit boards are manually disassembled, harmful electrical components such as batteries, transformers, etc. Go to the secondary crusher to crush the material to less than 5mm.

[0071] step (2)

[0072] The above materials were put into electrostatic separation equipment for electrostatic separation, and 280 kg of metal-enriched bodies and 720 kg of pl...

Embodiment 2

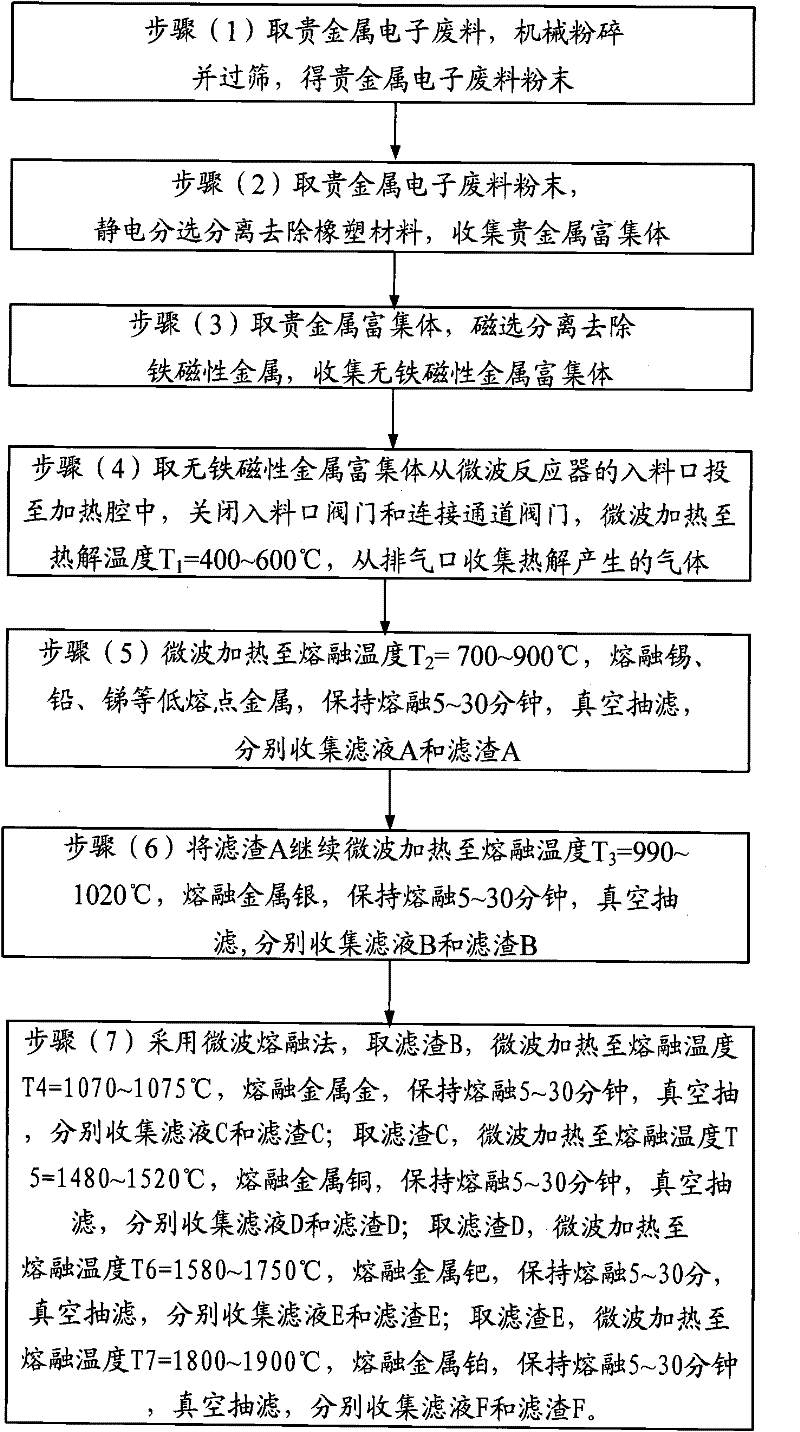

[0087] Embodiment two (the process flow diagram B of this embodiment is as image 3 shown)

[0088] Raw material components and steps (1)~(6) are the same as embodiment one, difference is that the pyrolysis temperature T of this embodiment two 1 =600°C, melting temperature T 2 =900°C, melting temperature T 3 =1020°C, the vacuum pressure during all the vacuum filtration processes is 0.5 atmospheres, and the melting time is 10 minutes.

[0089] Step (7): using acid-soluble filtration method and electrolysis, extraction and other methods

[0090] Inject sulfuric acid (10%) into the feed port to submerge the filter residue, dissolve metal copper and its oxides, chlorides, etc. in the acid solution and filter through a filter screen. After 30 minutes, close the vacuum pump and the discharge port valve, open the lower pipeline valve, vacuum filter, and the base metal salt solution automatically flows into the vacuum chamber. Open the outlet valve and take out the base metal sal...

Embodiment 3

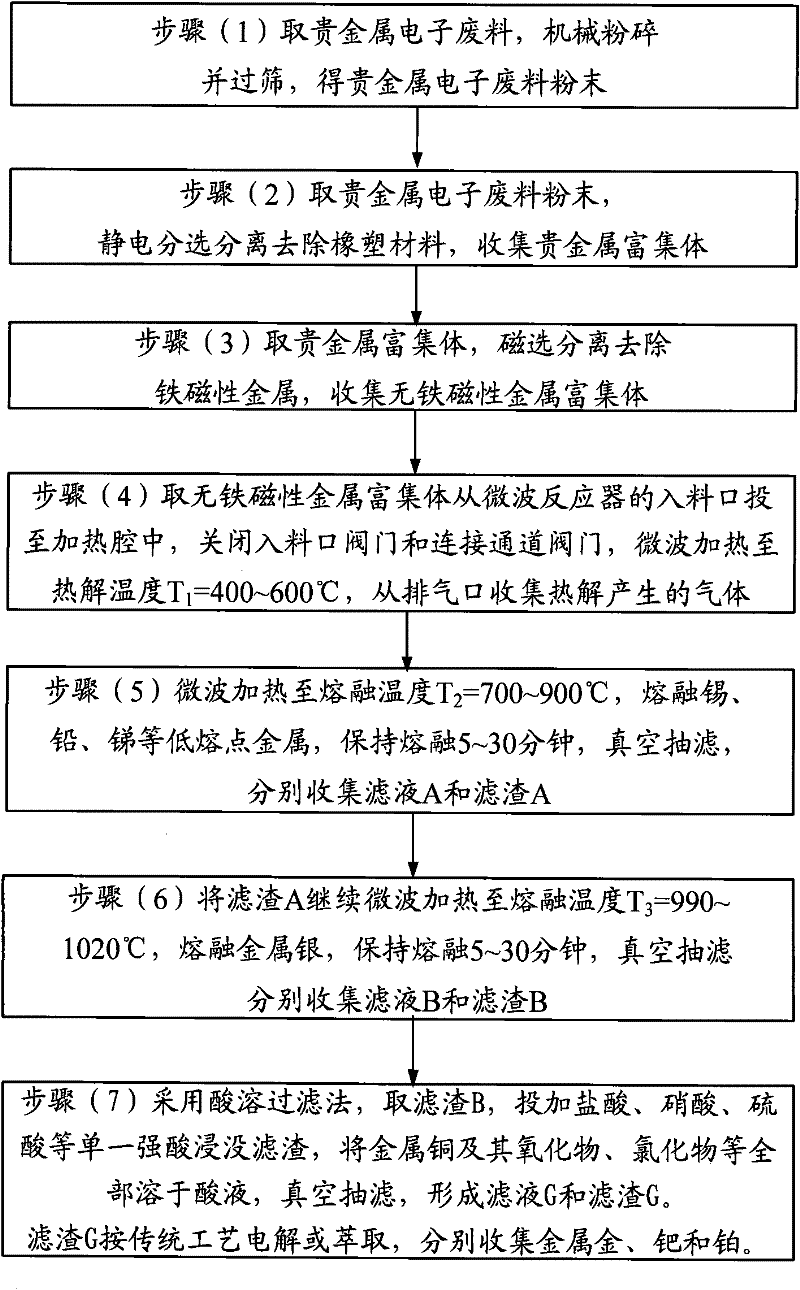

[0092] Embodiment three: (the process flow diagram C of the present embodiment is as Figure 4 shown)

[0093] Raw material components and steps (1)~(6) are the same as embodiment one, the difference is that the pyrolysis temperature T of this implementation three 1 =500°C, melting temperature T 2 =800°C, melting temperature T 3 =1000°C, the vacuum pressure in all vacuum filtration processes can be 0.2 to 0.5 atmospheres, and the melting time can be 5 to 30 minutes.

[0094] Step (7): using acid-soluble filtration method and microwave melting method

[0095] Sulfuric acid (10%) is injected into the material inlet to submerge the filter residue, and metal copper and its oxides, chlorides, etc. are all dissolved in the acid solution and filtered. After 30 minutes, close the vacuum pump and the discharge port valve, open the lower pipeline valve, vacuum filter, and the base metal salt solution automatically flows into the vacuum chamber. Open the outlet valve and take out th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com