Method for directionally producing biomass charcoal, biomass oil and biomass gas through microwave catalytic pyrolysis of biomass

A technology of biomass charcoal and microwave catalysis, which is applied to the preparation of biofuels and liquid hydrocarbon mixtures, and the treatment of hydrocarbon oils. The effect of moderate solution temperature and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific steps of the method for directional production of biomass charcoal, biomass oil and biomass gas by utilizing microwave catalytic pyrolysis of biomass are as follows:

[0033] Step 1, first remove impurities, crush and dry the biomass of Eupatorium adenophorum to obtain biomass particles with a particle size of 3-10mm, add the catalyst according to the mass ratio of biomass to anhydrous sodium carbonate catalyst of 10:0.5 and Mix evenly, then heat to 500°C at a heating rate of 30°C / min and perform pyrolysis in a microwave reactor for 30 minutes to obtain gas products and solid products;

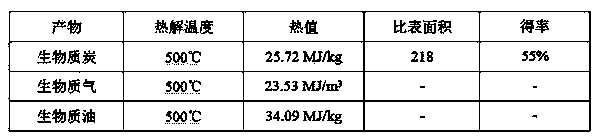

[0034]Step 2. Quickly condense the gas product obtained in step 1 at -5°C, and the condensable part is directly condensed into liquid high-quality biomass oil, and the non-condensable gas is a high calorific value gas fuel, and the gas and liquid products are detected Analysis, detection result is as shown in table 1;

[0035] Step 3, take out the solid product obtained in...

Embodiment 2

[0040] The specific steps of the method for directional production of biomass charcoal, biomass oil and biomass gas by utilizing microwave catalytic pyrolysis of biomass are as follows:

[0041] Step 1, first remove impurities, crush and dry the biomass of Eupatorium adenophorum to obtain biomass particles with a particle size of 3 to 10 mm, add the catalyst according to the mass ratio of biomass to anhydrous potassium carbonate catalyst of 10:1 and Mix evenly, then heat to 600°C at a heating rate of 40°C / min, and perform pyrolysis in a microwave reactor for 60 minutes to obtain gas products and solid products;

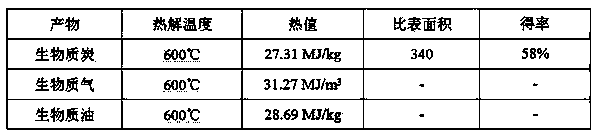

[0042] Step 2. Quickly condense the gas product obtained in step 1 at 8°C, and the condensable part is directly condensed into a liquid-phase high-quality biomass oil, and the non-condensable gas is a high calorific value gas fuel, and the gas and liquid products are detected and analyzed , the test results are shown in Table 2;

[0043] Step 3. Cool the solid produc...

Embodiment 3

[0048] The specific steps of the method for directional production of biomass charcoal, biomass oil and biomass gas by utilizing microwave catalytic pyrolysis of biomass are as follows:

[0049] Step 1. First remove impurities, crush and dry the biomass of Eupatorium adenophorum to obtain biomass particles with a particle size of 3-10 mm. Add the catalyst according to the mass ratio of biomass to alumina catalyst of 10:2 and mix evenly , and then heated to 700°C at a heating rate of 50°C / min to perform pyrolysis in a microwave reactor for 40min to obtain gas products and solid products;

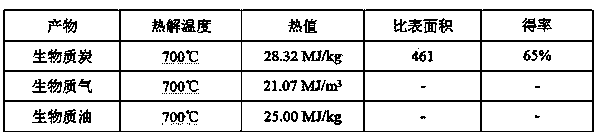

[0050] Step 2. Quickly condense the gaseous product obtained in step 1 at 10°C, and the condensable part is directly condensed into a liquid-phase high-quality biomass oil, and the non-condensable gas is a high-calorific value gas fuel, and the gas and liquid products are detected and analyzed , the test results are shown in Table 3;

[0051] Step 3. Cool the solid product obtained in step 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com