Device and method for preparing biological oil, activated carbon and combustible gas by use of biomass poly-generation

A poly-generation, biomass technology, applied in the preparation of biofuels, liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of increasing heating and cooling energy consumption, reducing the quality of bio-oil, increasing processing costs, etc. , the effect of increasing production and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

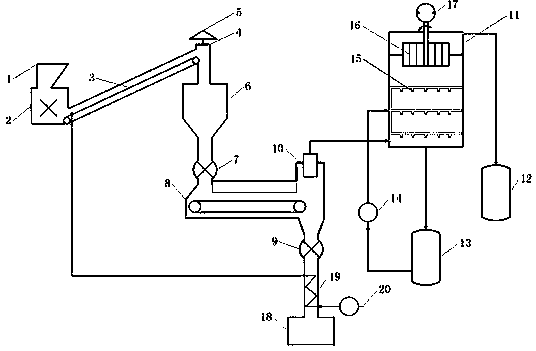

[0033] Below in conjunction with accompanying drawing and embodiment mode, the patent of the present invention is described in further detail:

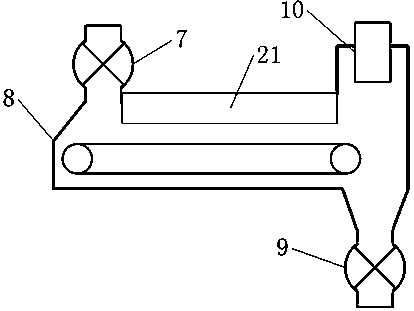

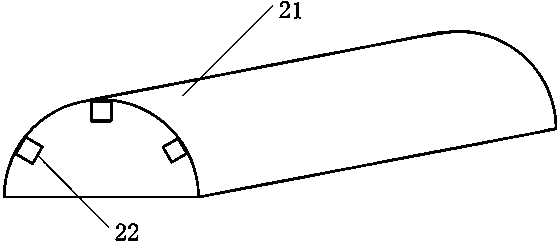

[0034] see figure 1 - Figure 4c , the device and method for preparing bio-oil, activated carbon and combustible gas by biomass polygeneration of the present invention, the biomass pretreatment device is integrated with the oil, charcoal, and gas polygeneration device; the device includes a raw material cutting device 2, a material Conveyor belt 3, filter screen 4, rain cover 5, silo 6, horizontal grate furnace microwave pyrolysis device 8, first rotary sealing device 7, second rotary sealing device 9, porous metal filter device 10, Condensing device 11, gas storage bottle 12, oil storage tank 13, activated carbon storage tank 18, gas-solid heat exchanger 19.

[0035]The upper part of the raw material cutting device 2 is provided with a material inlet 1, and the bottom is equipped with a material conveyor belt 3, which is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com