Fine coal gasification method with fly ash compulsory recycling system

A fly ash and pulverized coal technology, which is applied in the field of pulverized coal gasification with fly ash forced reinjection system, can solve the problems of low conversion rate of pulverized coal and uneconomical operation of gasifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

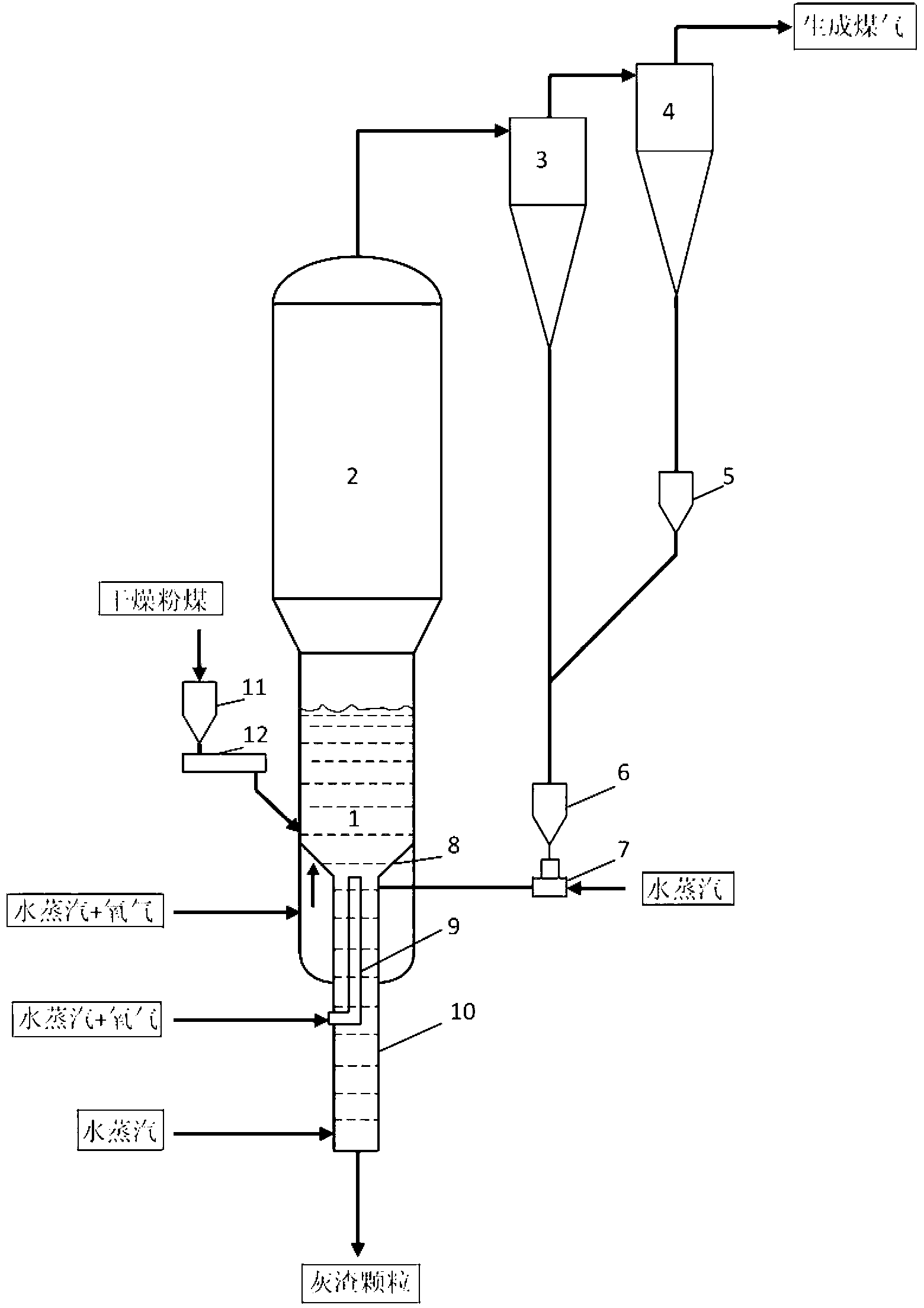

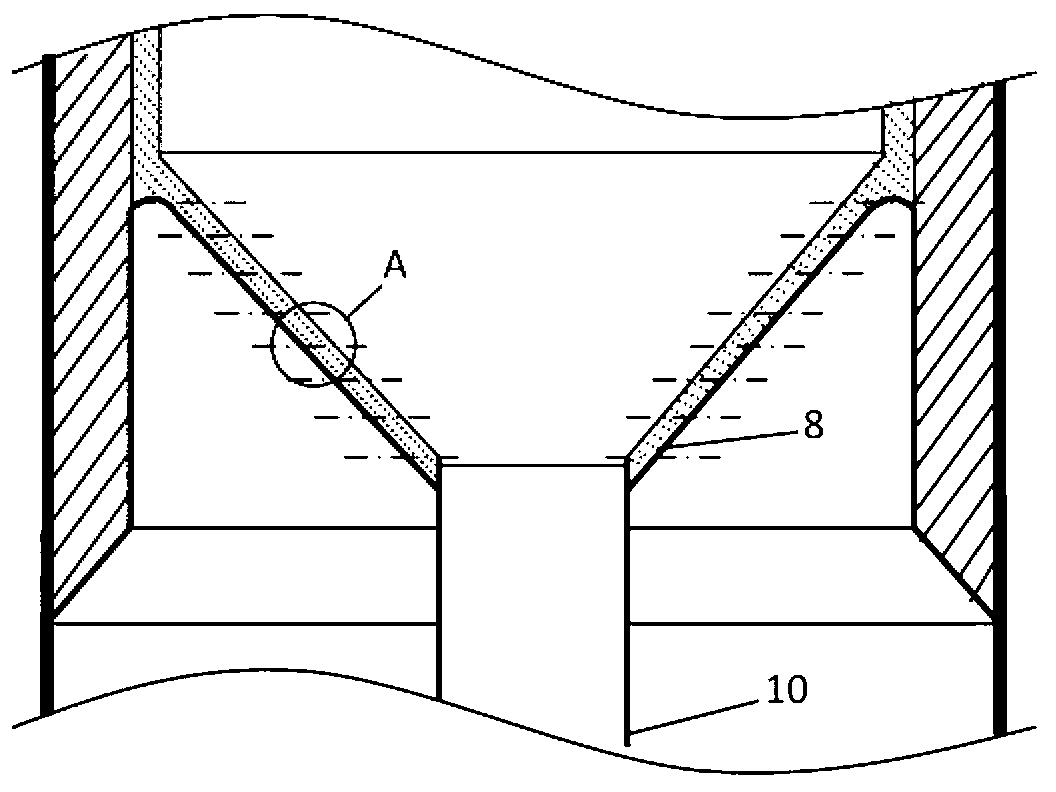

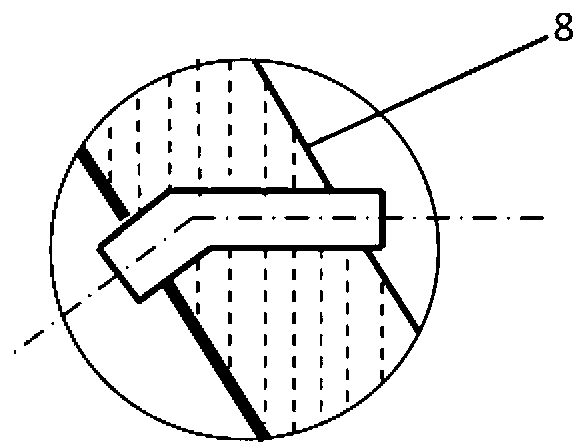

[0028] A pulverized coal gasification method with a fly ash forced reinjection system, characterized in that: the gas generated by the pulverized coal gasification reaction entrains fly ash particles, and the gas entrained with fly ash particles passes through a cyclone separator to separate the gas from the fly ash particles, The separated fly ash particles enter under the gas distribution plate 8 in the gasification furnace for recombustion and gasification reaction.

[0029] A pulverized coal gasification method with a fly ash forced reinjection system specifically includes the following steps:

[0030] a. Put the pulverized coal into the coal hopper 11, and the pulverized coal enters the dense phase section 1 of the gasifier through the quantitative screw 12;

[0031] b. The central jet tube 9 below the gas distribution plate 8 injects the first gasification agent, and the first gasification agent blows pulverized coal into the fluidized material in the dense phase section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com