Device and method for preparing high-calorific value combustible gas through biomass gasification and melting

A gasification melting, high calorific value technology, applied in the production of combustible gas, climate sustainability, granular/powder fuel gasification, etc. investment and other issues, to achieve the effect of improving energy utilization efficiency, improving energy utilization rate, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

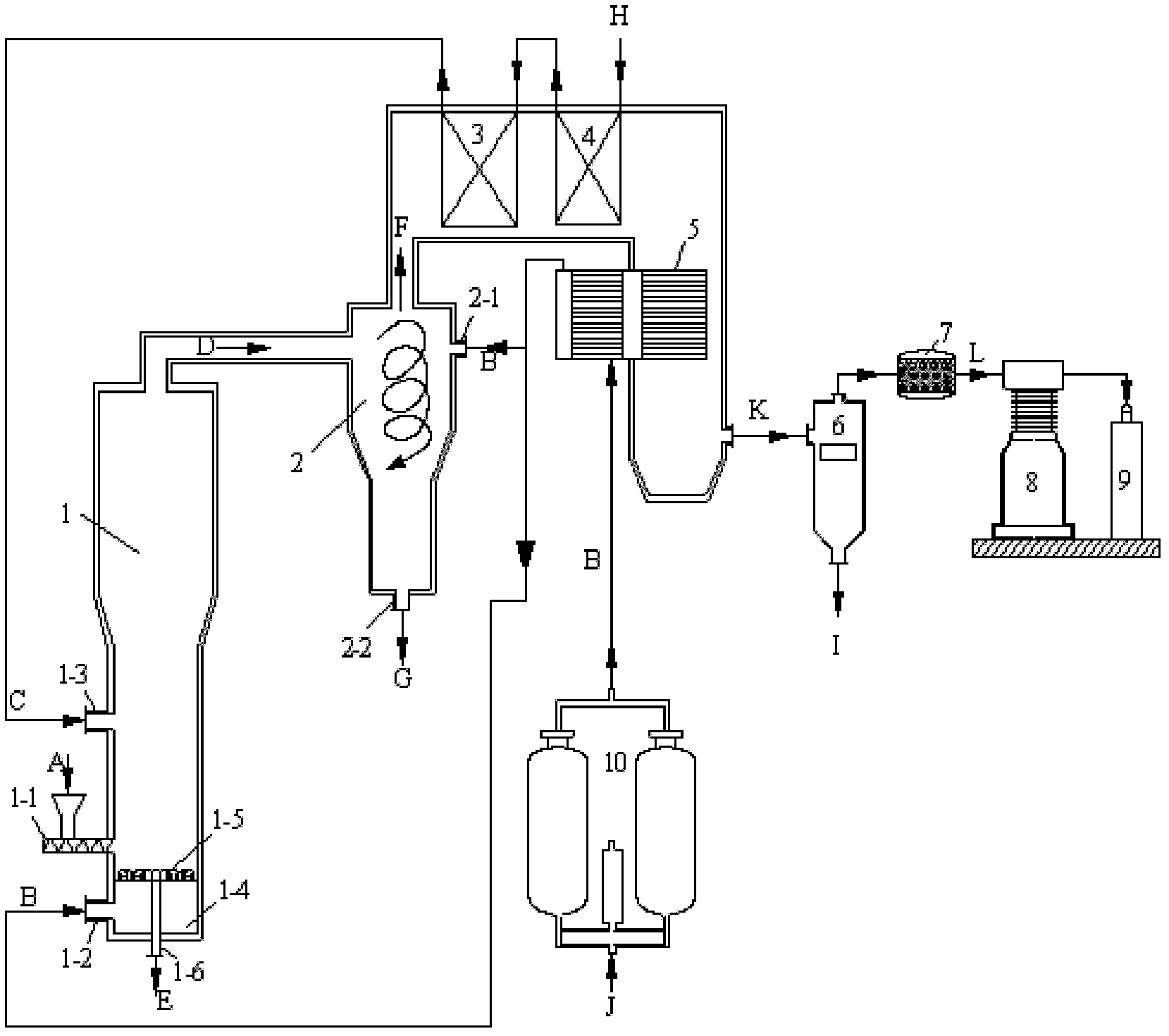

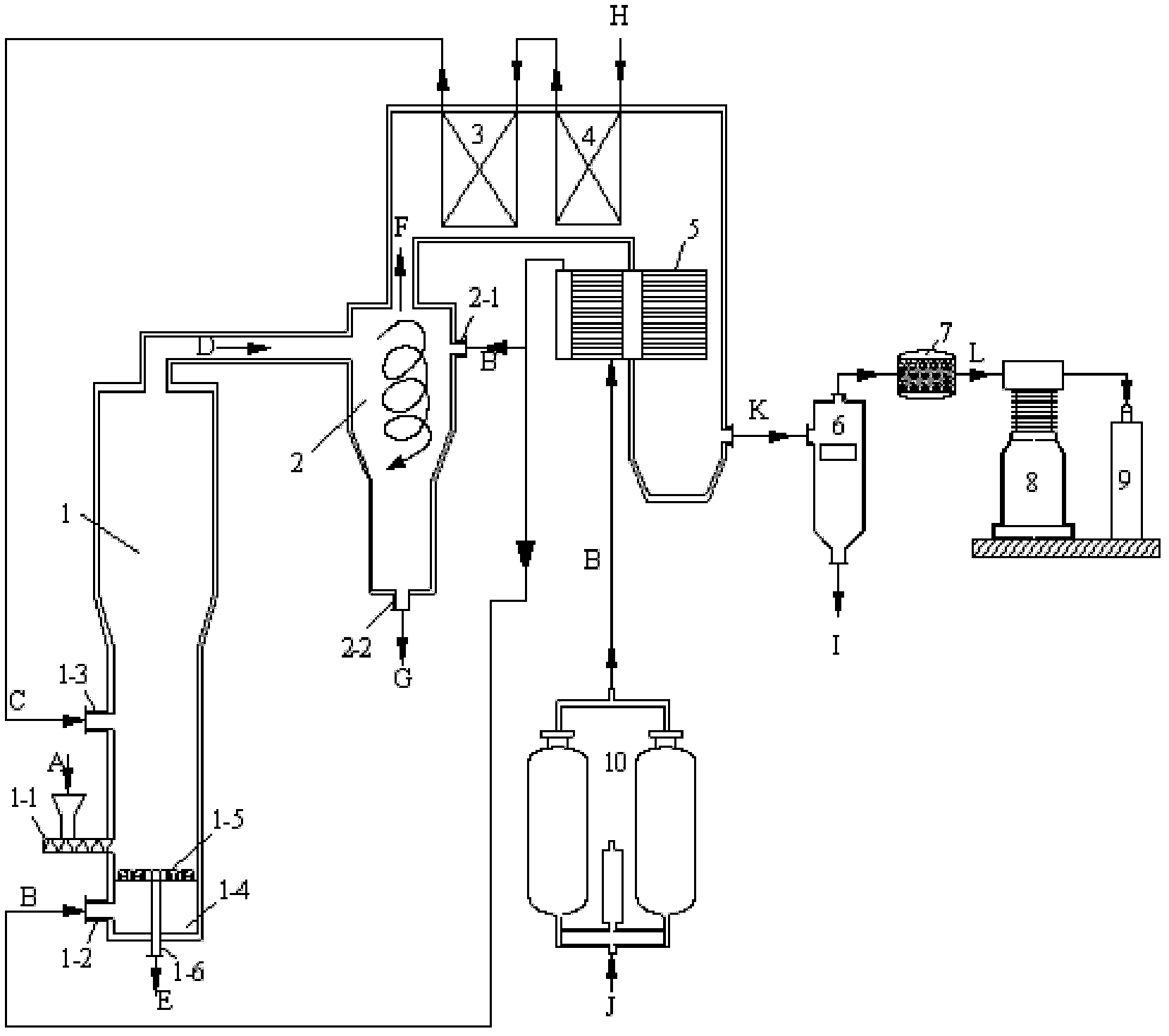

[0030] Embodiment: The device of the present invention is mainly composed of a fluidized bed gasification reactor 1, a cyclone melting furnace 2, a superheater 3, an economizer 4, a heat pipe heat exchanger 5, a bag filter 6, a desulfurization tower 7, a compression device 8, The air storage tank 9 and the air separation unit 10 are composed.

[0031] The fluidized bed gasification reactor 1 is composed of a gasification reaction zone and an air chamber 1-4 at the bottom, and an air distribution plate 1-5 is arranged between the air chamber 1-4 and the gasification reaction zone. The side wall and bottom of the air chamber 1-4 are respectively provided with an air inlet 1-2 and a slag discharge port 1-6; the side wall of the gasification reaction zone of the fluidized bed gasification reactor 1 is provided with Steam inlet 1-3 and feeder 1-1; the upper part of the gasification reaction zone of the fluidized bed gasification reactor 1 is connected with the inlet of the cyclone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com