Method and apparatus for particle recycling in multiphase chemical reactors

a chemical reactor and multi-phase technology, applied in the details of gasification processes, combustible gas production, fuel gas production, etc., can solve the problems of inability to reach dipleg, rapid and easy eroded, and insufficient, so as to reduce the quantity of ash, simplify the gasification system, and reduce the effect of capital investmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

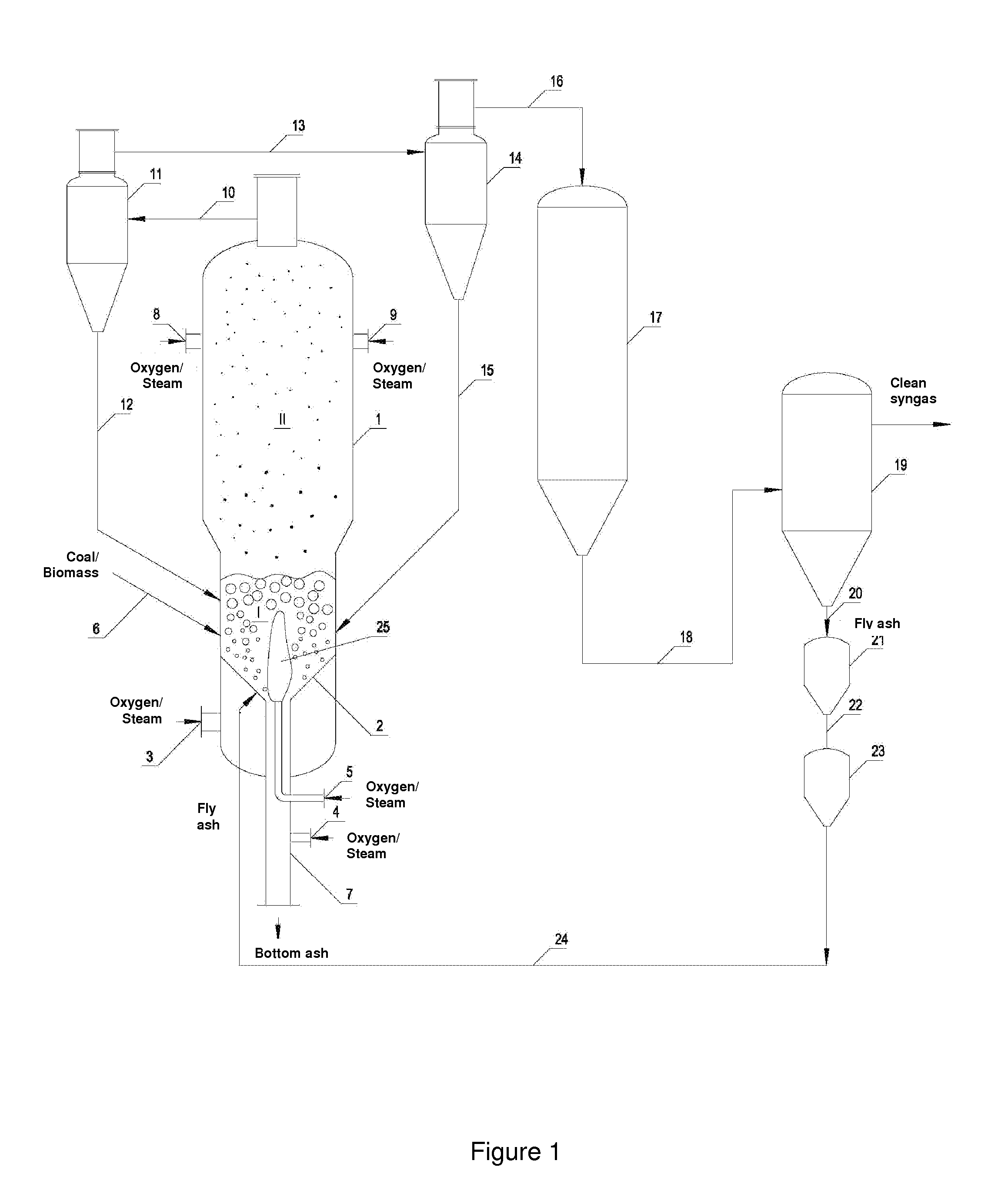

[0043]A pneumatic gas conveying system was used to delivery the fine fly ash, collected from a baghouse with or without an operational second-stage cyclone, into a high temperature (higher than the hemisphere temperature, or T3, for the fly ash) zone, which is also O2-rich (>10%), of the gasifier.

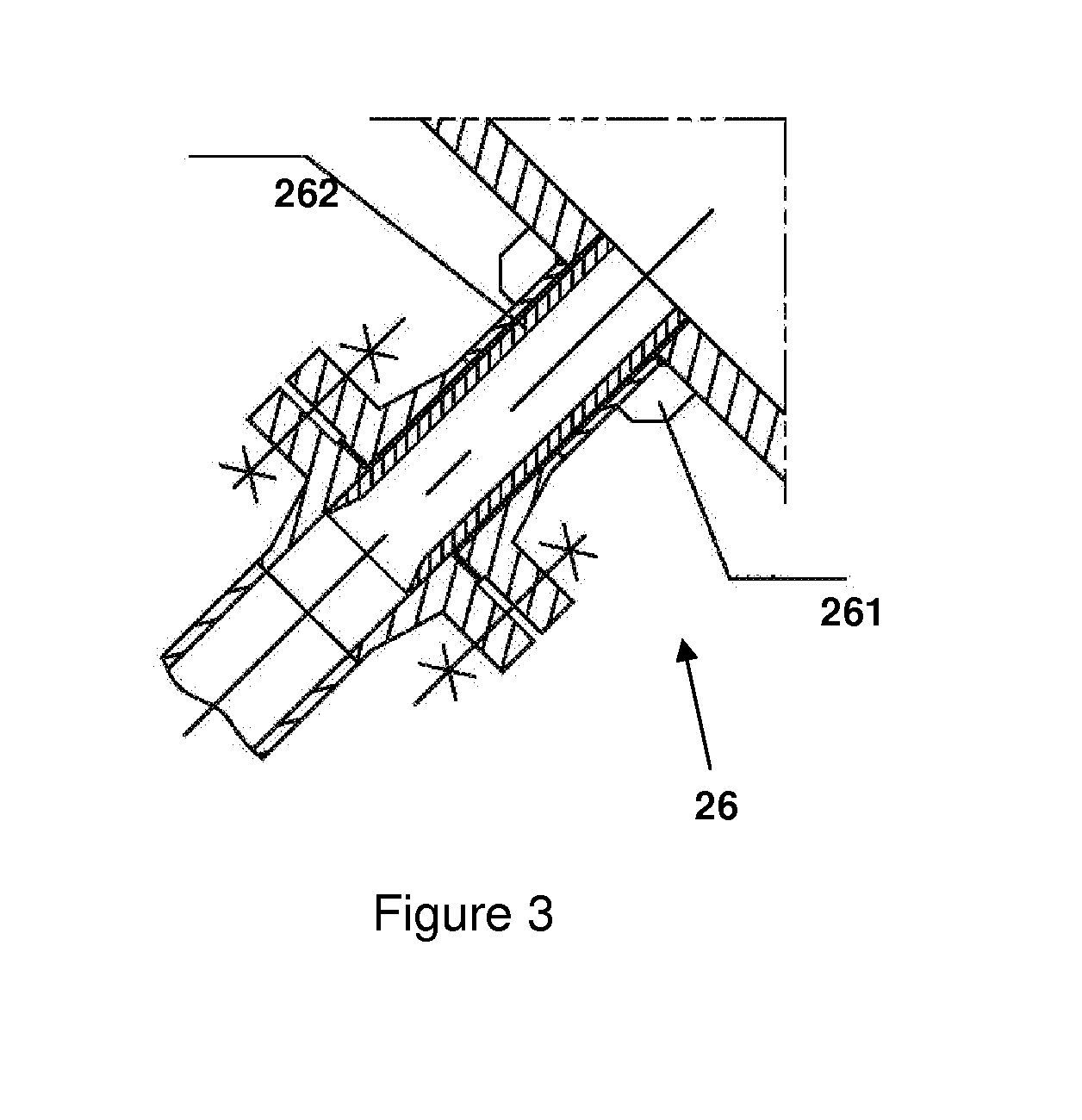

[0044]Pneumatic Convey System Design A fully automatic programmable logic control (PLC) system was used, and interlock protections were designed. The connection to gasifier was through a D80 pipe installed with an angle of approximately 45° to the vertical center pipe (5) and enters through the distribution plate or grid board.

[0045]Control experiments were performed wherein the fly ash was not returned to the high-temperature zone. Specifically, a coal gasification system, as described in FIG. 1, was operated for 48 hours, wherein the fly ash were not returned to the gasifier.

[0046]The system was then operated for 72 hours, wherein the fly ash was returned to the high-temperature region vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening temperature | aaaaa | aaaaa |

| softening temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com