Method for preparing calcium carbide and synthesis gas through thermal oxidation reaction and calcium carbide reactor

A reactor and synthesis gas technology, which is applied in the direction of granular/powder fuel gasification, carbide, calcium carbide, etc., can solve the problems of low CO content in by-products, increase operating costs, increase process steps, etc., and achieve by-products The effect of large gas volume, small investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

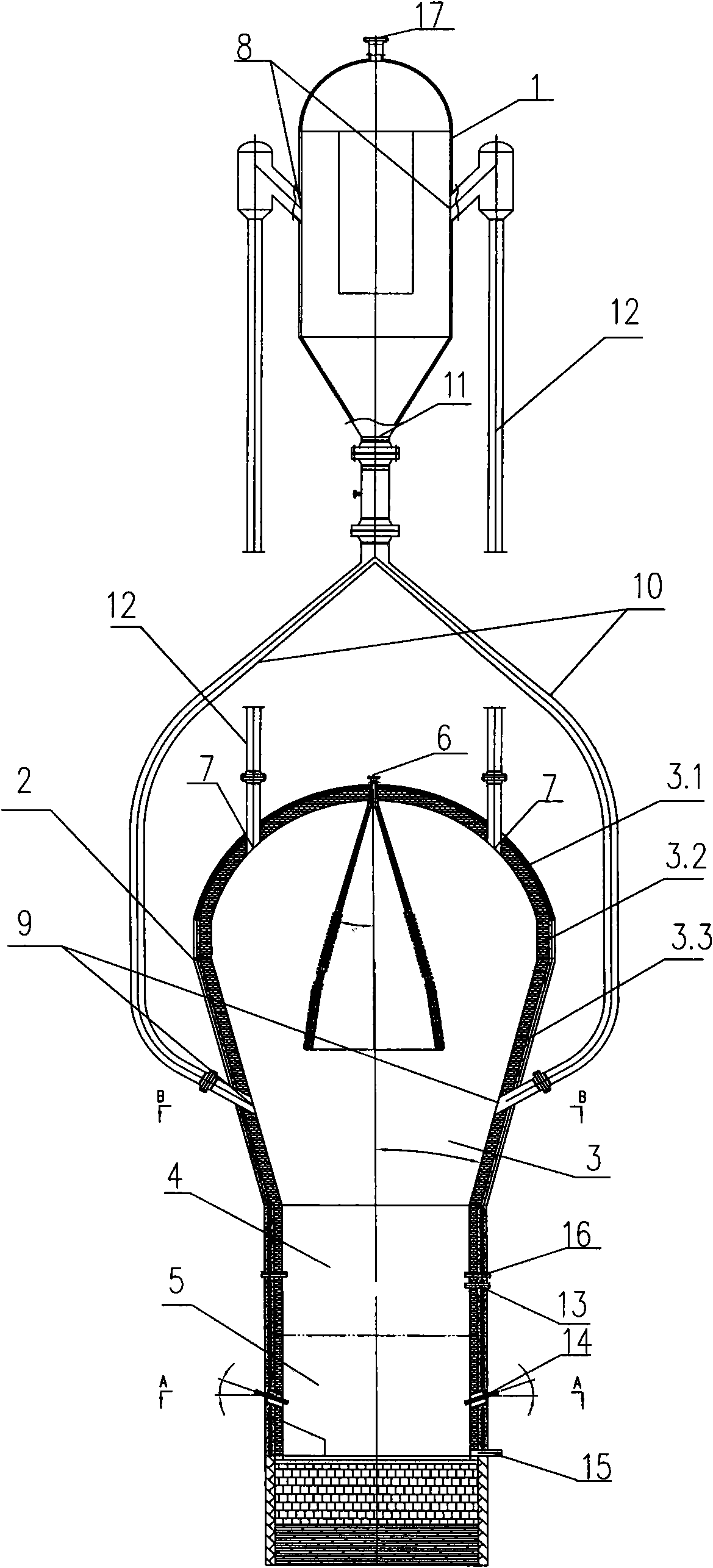

[0040] The weight ratio of raw materials: pulverized coal: calcium carbonate is 2.2:1, and the particle size is 0.15mm.

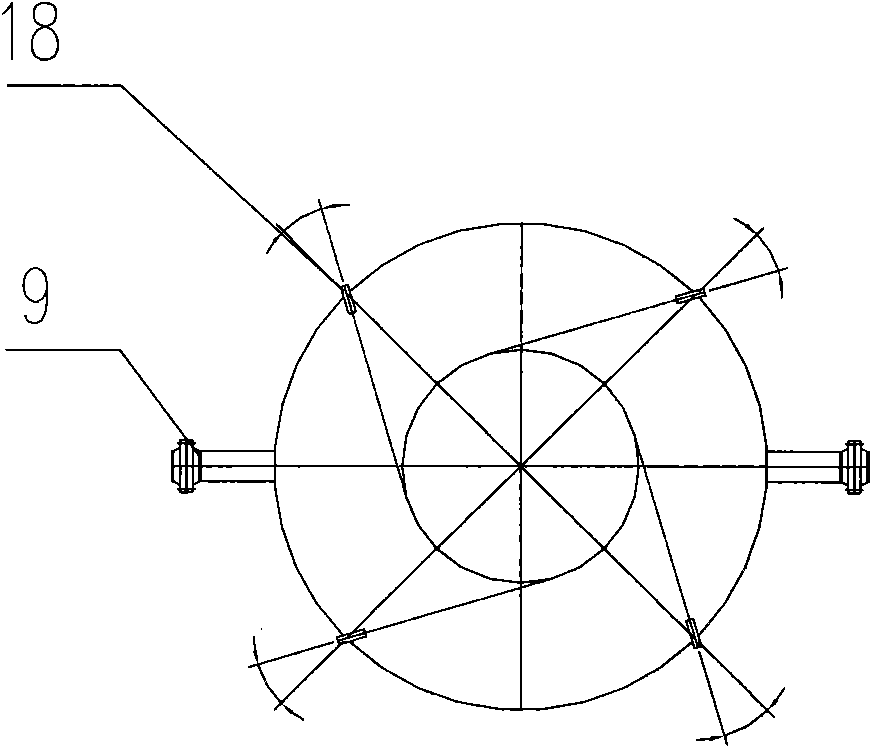

[0041] One third of the weight of the above-mentioned raw materials is put into the closed reaction furnace 2 from the first feeding port 6 through the screw pressurized feeder, and the remaining two thirds are fed by the pressurized feeder from the second feeding port 18. Put into closed reaction furnace 2 (the carrier gas temperature of this part of the material is 200 ° C, which is the part of the chilled CO gas separated by the gas-solid separator), and the control feeding speed is 7m / s and the pressure is 2.0MPa, Calcium carbonate is decomposed into calcium oxide and CO at high temperature (above 600°C) in preheating chamber 3 2 At the same time, part of the pulverized coal also interacts with the CO in the preheating chamber 3 2 An endothermic reaction occurs to generate CO, and the remaining part of pulverized coal and calcium oxide are combined wit...

Embodiment 2

[0043] The weight ratio of raw materials: blue carbon: calcium oxide is 2.5:1, and the particle size is 0.25mm.

[0044] The above-mentioned raw materials are put into the closed reaction furnace 2 through the first feeding port 6 and the second feeding port 18 respectively through the screw press feeder, and half of the total weight of the raw materials is added from the first feeding port 6. , the rest is added from the second feed port 18, (the temperature of the carrier gas of this part of the material is 220 ° C), the control feeding speed is 10m / s, the pressure is 4.0MPa, part of the blue carbon and the CO in the preheating chamber 3 2 An endothermic reaction occurs to generate CO, and the remaining blue carbon and calcium oxide are combined with the high-temperature CO and CO from the gasification chamber 4 and the reaction chamber 5 in the preheating chamber. 2 After the contact heat exchange is carried out, they descend into the gasification chamber together; Every 1...

Embodiment 3

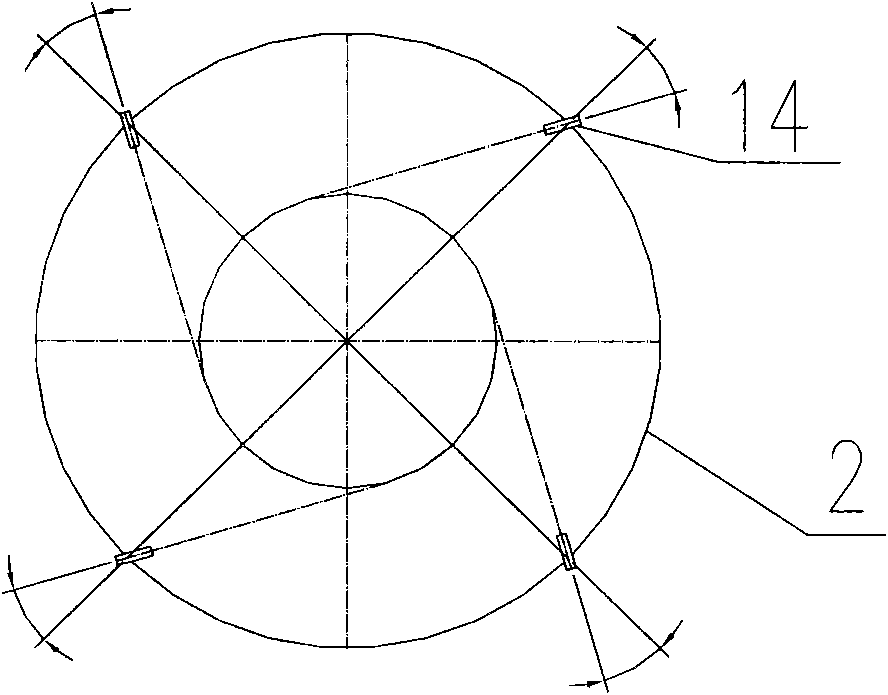

[0046] The weight ratio of raw materials: pulverized coal: calcium oxide is 3:1, and the particle size is not more than 0.45mm.

[0047] The above-mentioned raw materials are put into the closed reaction furnace 2 from the first feeding port 6 and the second feeding port 18 through the screw pressurized feeder, and a quarter of the total weight of the raw materials is added from the first feeding port 6, and the remaining Part of it is added from the second feed port 18 (the carrier gas temperature of this part of the material is 210 ° C), the feeding speed is controlled to be 10 m / s, the pressure is 1.5 MPa, and the weight of pure oxygen and pulverized coal injected into the oxygen burner The mixture with a ratio of 0.5:1 was injected at a speed of 250 m / s, and the rest were the same as those in Example 1. The purity of 0.348 tons of calcium carbide generated per 1 ton of raw coal is 56%, and the amount of synthesis gas is 1500 liters / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com