Gas-solid reaction kinetic parameter analyzer

A kinetic parameter, gas-solid reaction technology, applied in the field of chemical analysis and testing, can solve the problems of difficult reaction kinetic parameters, dispersion of experimental data, not a differential reactor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

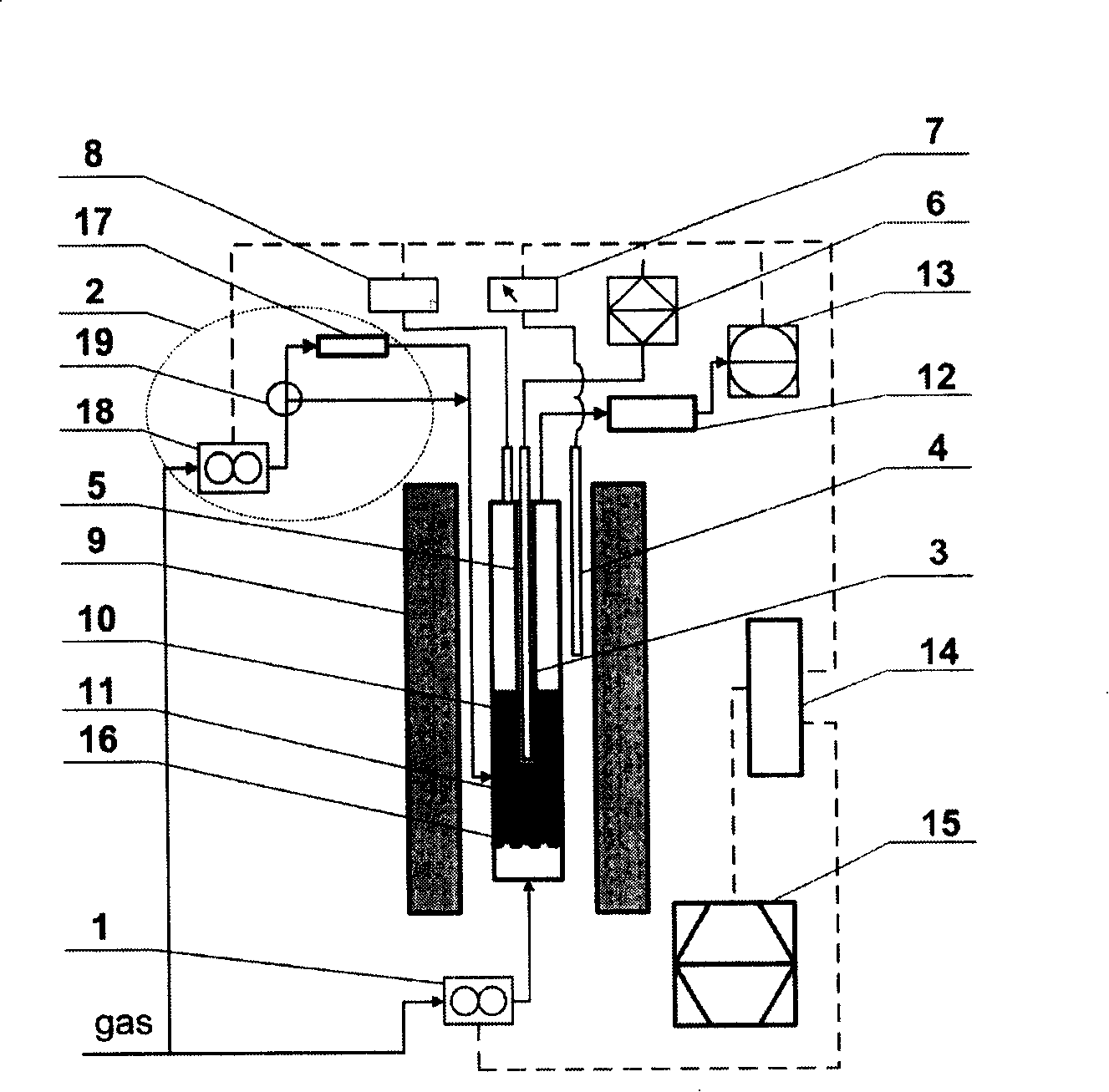

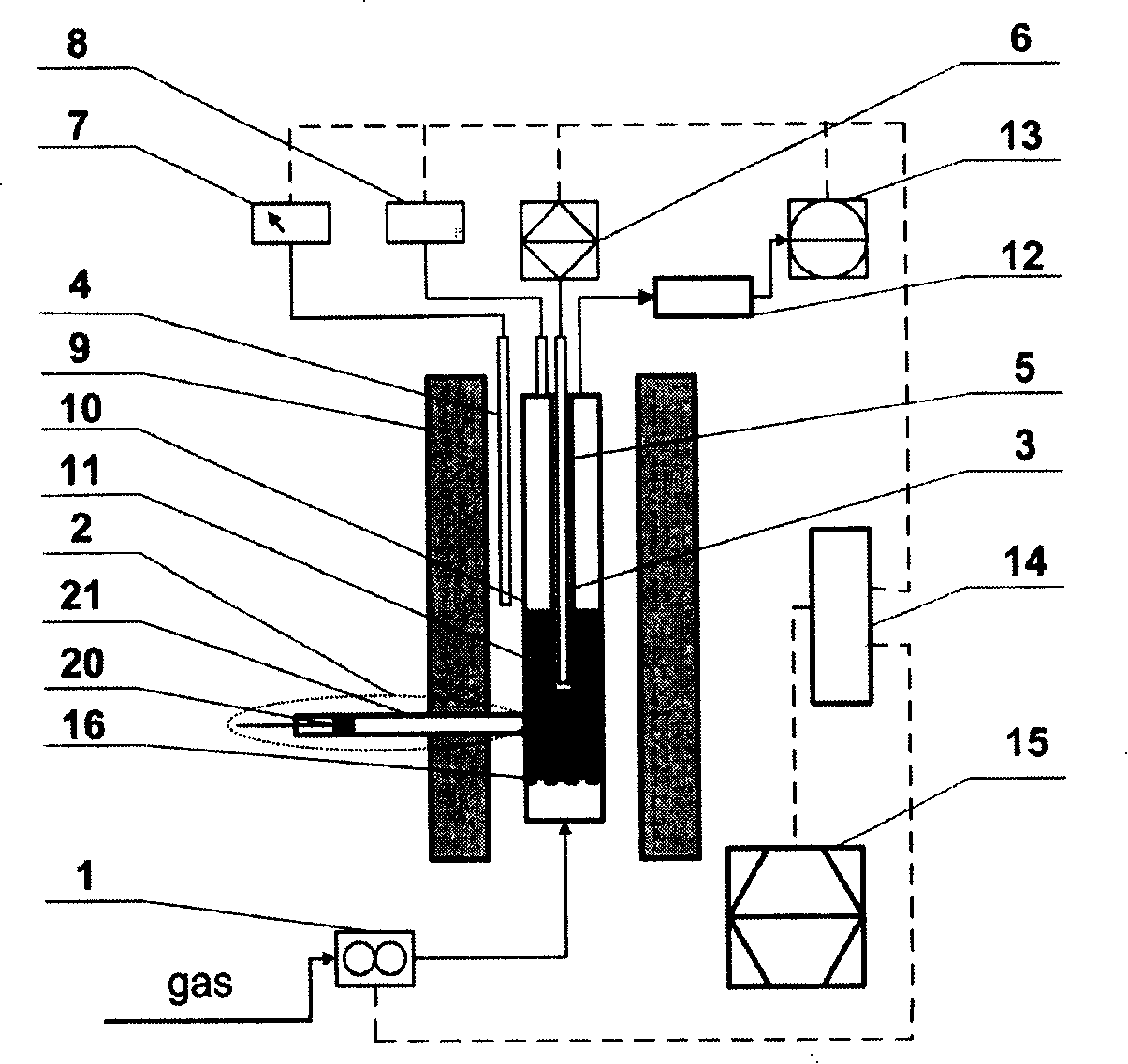

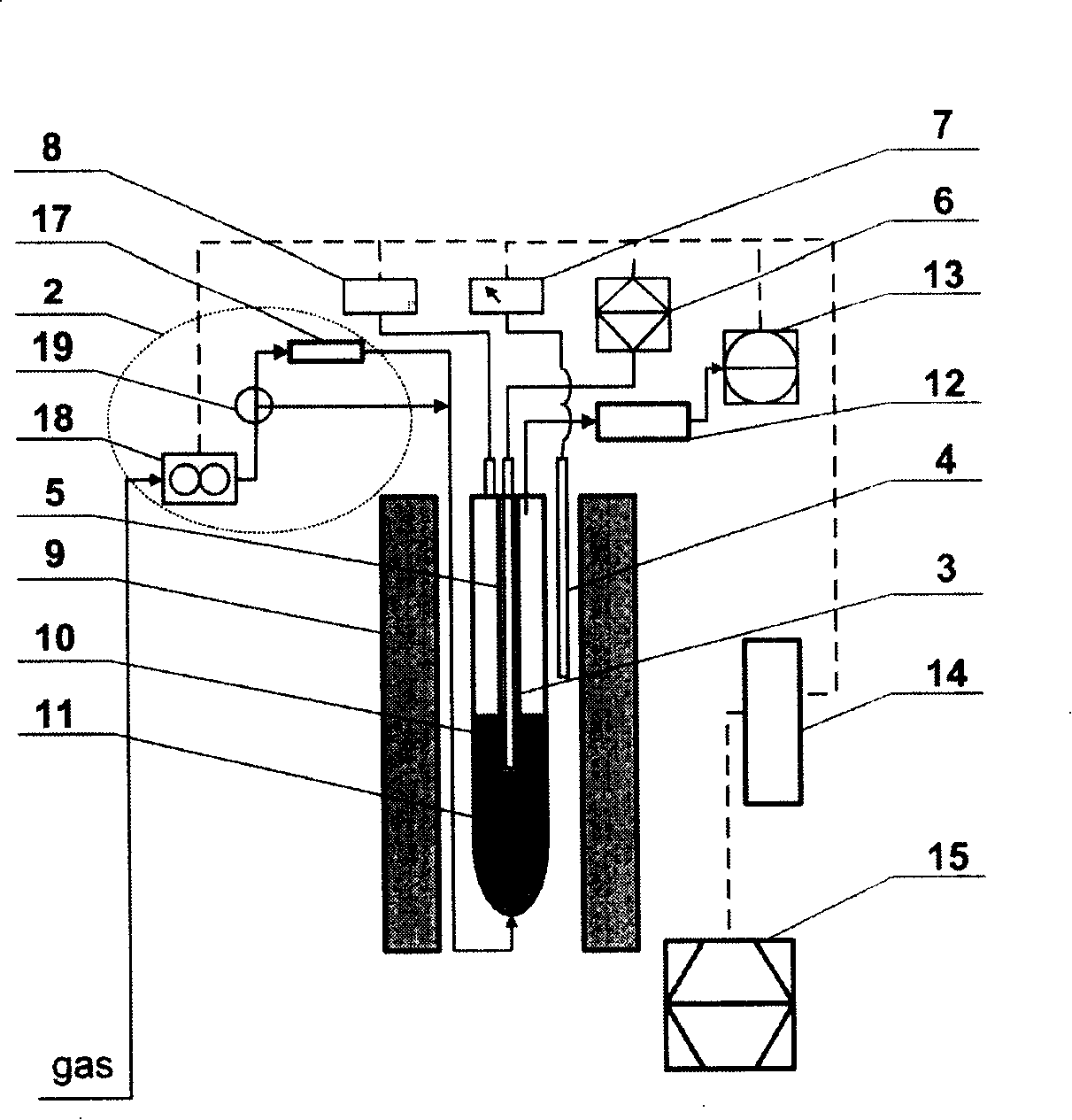

[0032] attached figure 2 Schematic diagram of the structure of a reaction kinetic parameter measurement device for implementing the present invention, which uses a micro fluidized bed as a reactor and the supply of solid reactants is realized by mechanical transportation. It is characterized in that the solid reactant supplier 2 is actually composed of a piston sleeve 21 with a piston 20 and a corresponding mechanical linkage device, and the piston sleeve 21 directly passes through the material supply pipe on the side wall of the reactor 10. In the solid bed material 11 of the reactor 10.

[0033] in the attached figure 2 In the measuring device shown, a weighed trace amount of solid reactant is put into the piston sleeve 21 and is located on the right side of the piston 20 with connecting rod close to the reactor 10 . At this time, as long as the switch of the solid reactant supplier 2 is turned on, the piston 20 with the connecting rod will quickly move to the right and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sectional area | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com