Low-cost solar energy tracking and condensing power generation method

A technology of solar tracking and solar energy, applied in the field of solar utilization, can solve the problems of high cost, high cost, and high cost, and achieve the effects of strong cycle power, reduced structural cost, and low wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

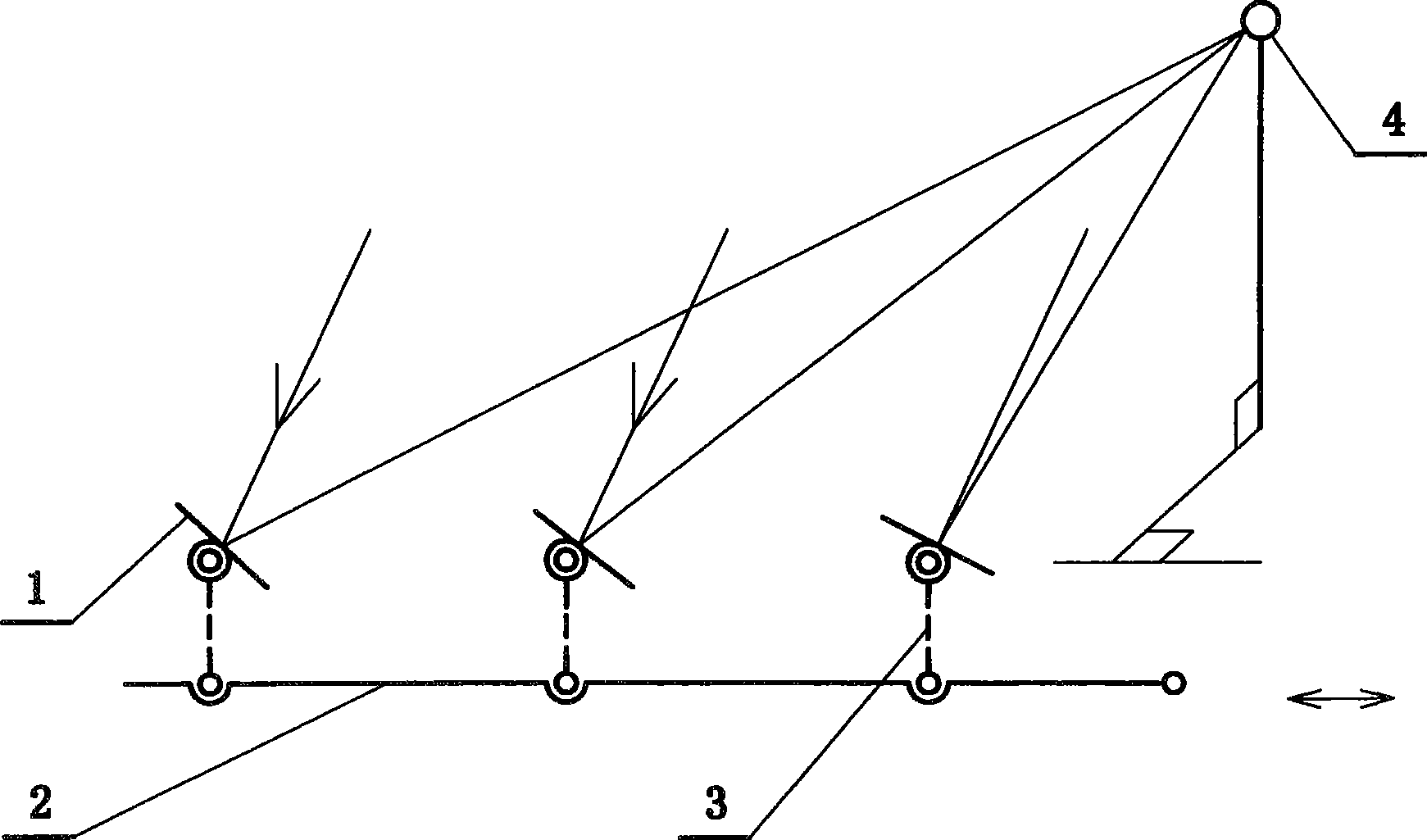

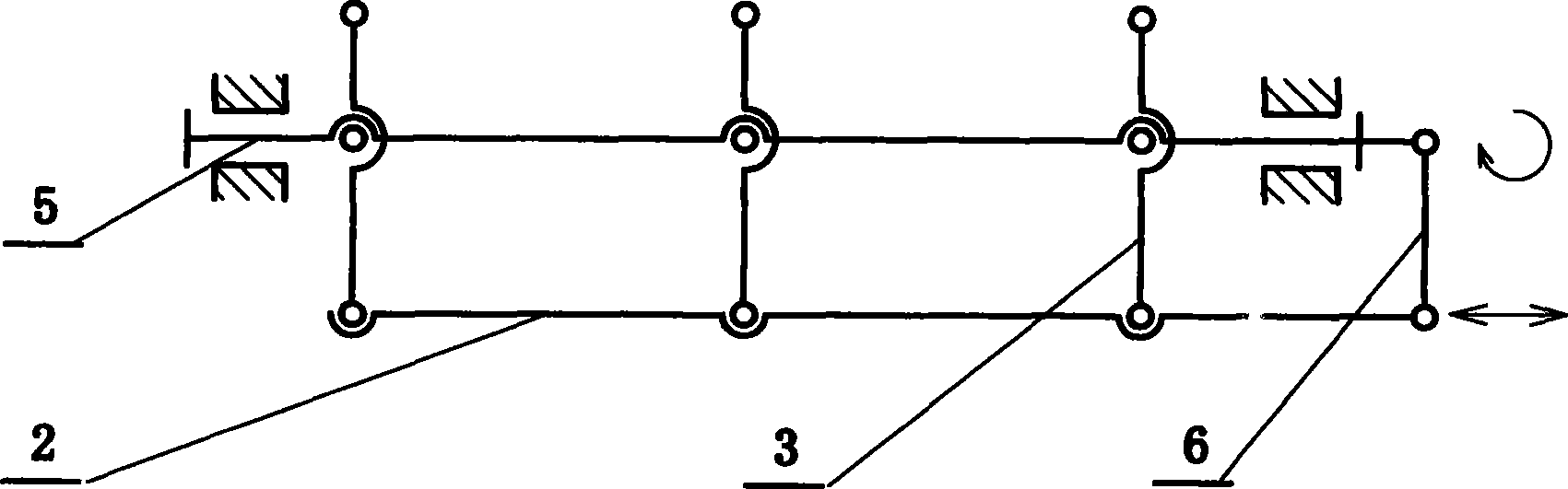

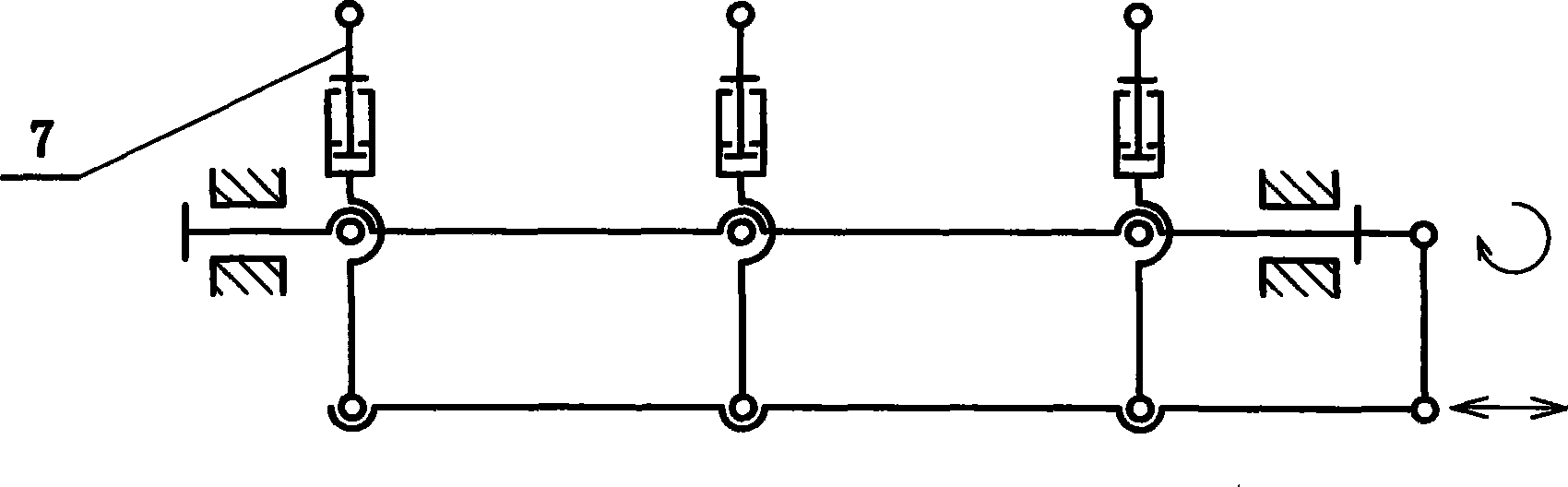

[0065] Embodiment 1: In order to realize low-cost solar reflectors tracking and concentrating, adopt as attached figure 1 In the connecting rod linkage mode shown, in order to realize reflection and light concentrating, each reflector 1 is installed at an appropriate installation angle, and under the action of the movement of the connecting rod 2, the parallel rocker 3 parallel to each other realizes synchronous deflection. The deflection of the sun's rays makes the reflected light change synchronously and focus on the receiver 4, forming a parallel link tracking and concentrating system. Generally, the two-dimensional deflection of the entire array is controlled by connecting rods in the vertical and horizontal directions. figure 1 Only one row of mirrors is shown in the figure, and when arranged in multiple rows, it becomes a mirror concentrating array. When the parallel linkage mechanism of each row is horizontal, the longitudinal deflection of the mirror is realized by the...

Embodiment 2

[0075]Embodiment 2: as attached Figure 13 The shown simple power heat pipe circulation system is filled with a part of the working medium (which can be water or other suitable solutions), and vacuumizes to remove the air seal so that the working medium can evaporate at a lower temperature. When the heater 22 is heated When the working medium starts to evaporate and expand to generate pressure, the check valve 21 is reversely closed, and the working medium starts to flow to the condenser 24, and after passing through the condenser, it is condensed into a liquid state and enters the return pipe 25. When the working medium in the heater evaporates, its internal The pressure gradually drops, and finally the pressure of the gas working medium before and after the condenser is close to the same, and the whole circuit becomes a connector, and the liquid working medium in the return pipe pushes the check valve to lead forward and enter the heater to start a new cycle. The graphics of...

Embodiment 3

[0086] Embodiment 3: as attached Figure 18 As shown, a thermodynamic booster power heat pipe cycle power generation system can be considered as a cycle system in which a thermodynamic booster system is used to replace the feed water pump on the basis of an ordinary thermal power generation system. The working process of the thermodynamic booster is:

[0087] a. Hydration. When the thermal booster 41 needs to replenish water, open the steam vent valve 43 of the condensed water tank 44 and close other valves, and the low-pressure liquid working medium from the condensed water tank 44 enters the booster 41 through the check valve 42 due to the principle of the connector.

[0088] b. Boost. After the booster replenishment is completed, the steam vent valve 43 is closed, and the steam extraction valve 46 is opened. Close the steam extraction valve 46 during the time, open the steam vent valve 37 with the evaporator 39 to continue heating and boosting.

[0089] c. Water supply. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com