Patents

Literature

68results about How to "Good data repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

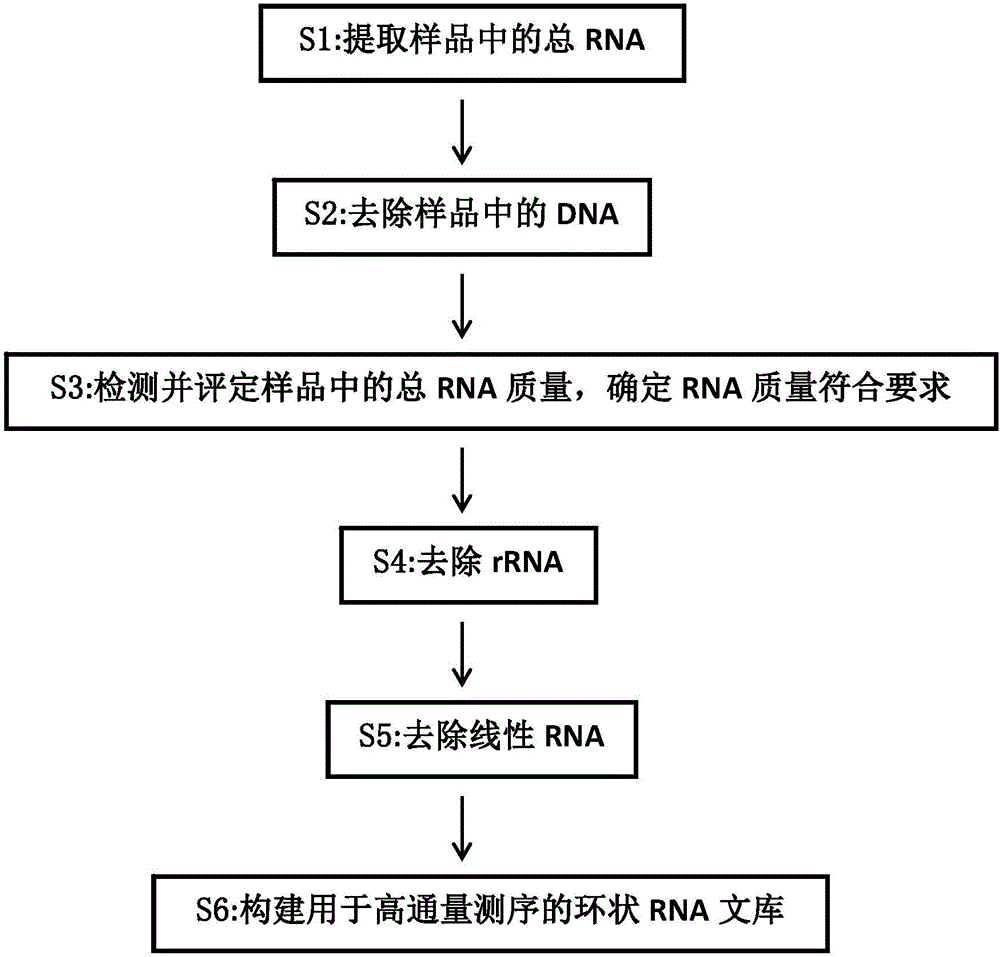

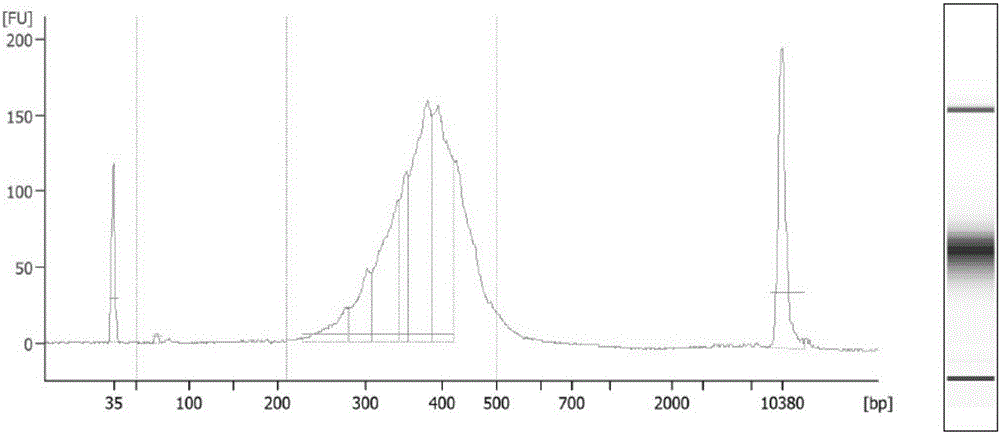

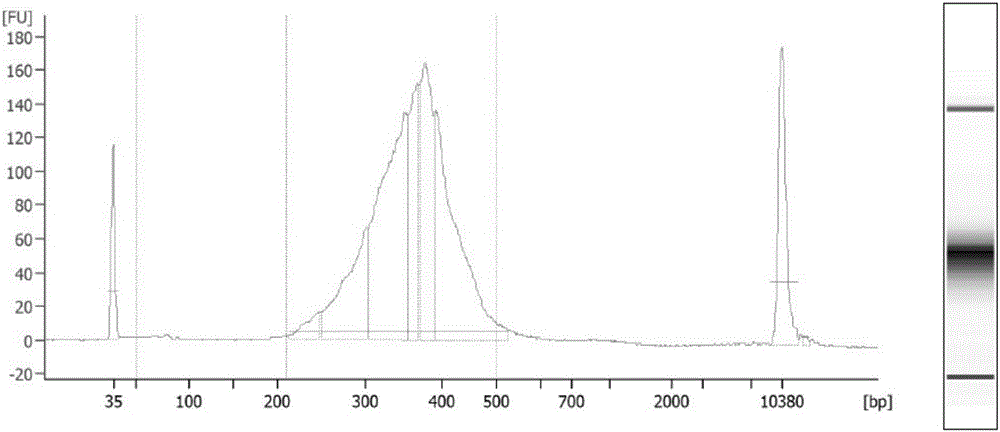

Establishing method of circular RNA high-throughput sequencing library and kit thereof

ActiveCN106801050AImprove detection efficiencyGood data repeatabilityMicrobiological testing/measurementLibrary creationTotal rnaRepeatability

The invention discloses an establishing method of a circular RNA high-throughput sequencing library and a kit thereof. The establishing method sequentially comprises the following steps: (S1) extracting total RNA from a sample; (S2) removing DNA in the sample; (S3) detecting and evaluating the quality of the total RNA in the sample, and determining that the RNA quality meets a requirement; (S4) removing rRNA; (S5) removing linear RNA; (S6) constructing the circular RNA library for high-throughput sequencing. The establishing method of the circular RNA high-throughput sequencing library, provided by the invention, is high in efficiency, stable, low in residual ratio of the rRNA, high in circular RNA detection efficiency, good in data reproducibility, and high in sequencing result verifying success rate, and is especially applicable to an FFPE tissue and other samples with poor RNA quality.

Owner:GUANGZHOU FOREVERGEN BIOTECH CO LTD +1

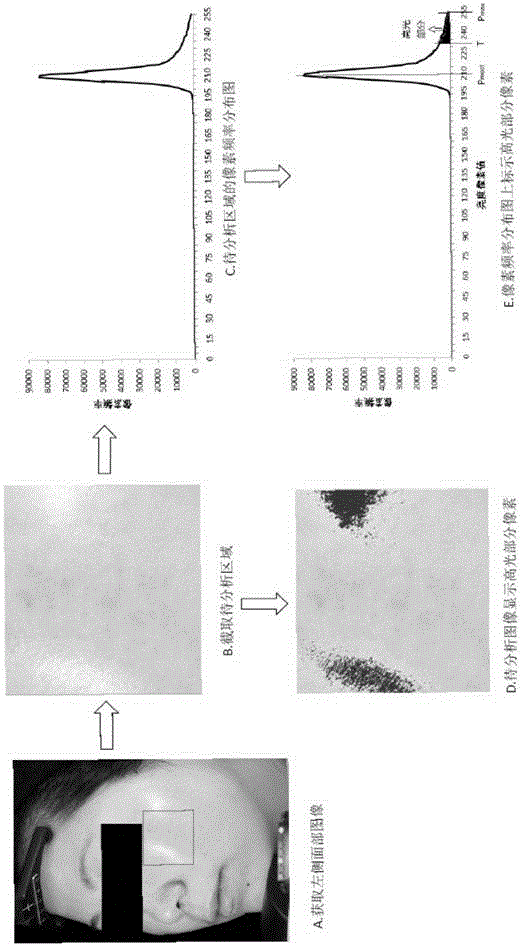

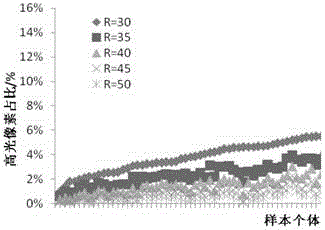

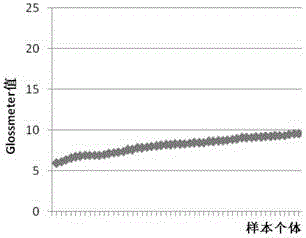

Image analysis method and apparatus for skin lustrousness

ActiveCN105427306AIncreased accuracy and sensitivityGood data repeatability and stabilityImage enhancementImage analysisImage analysisLight source

Owner:SHANGHAI JAHWA UNITED

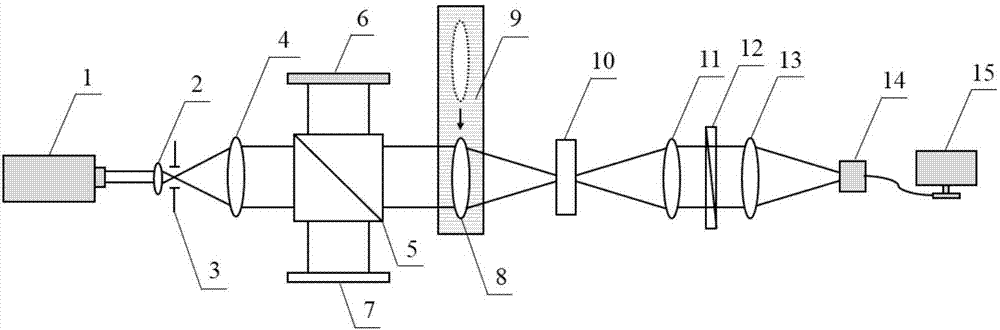

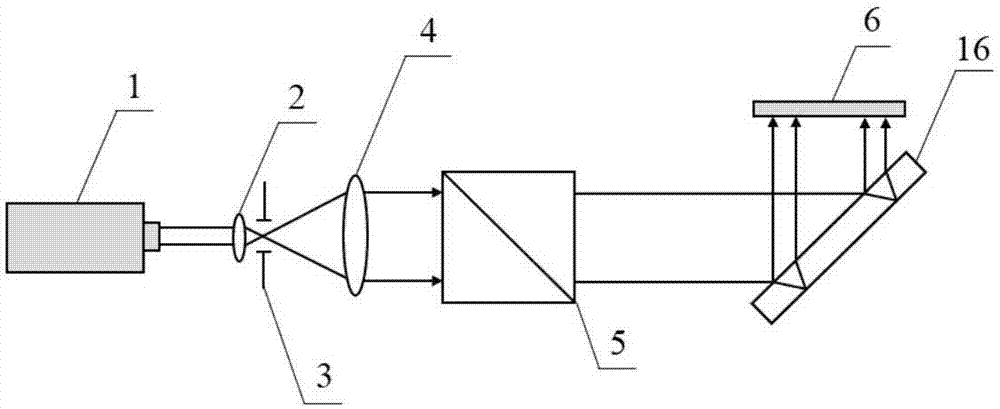

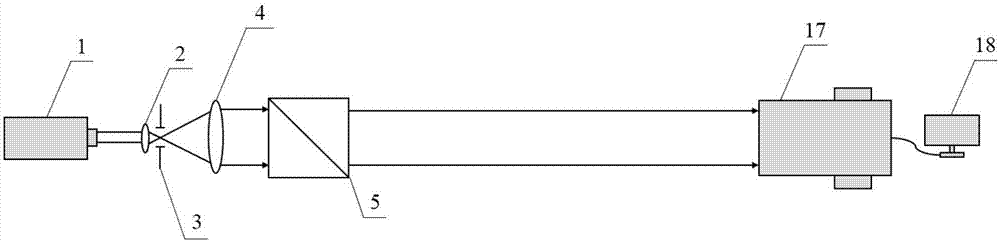

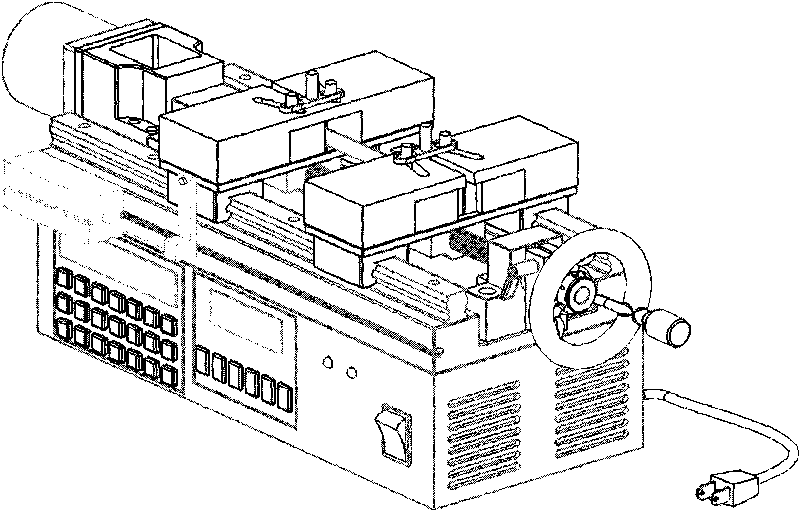

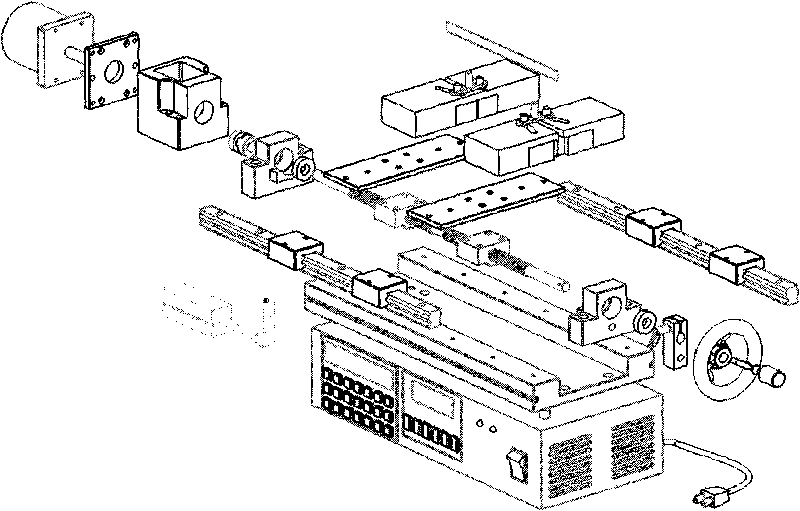

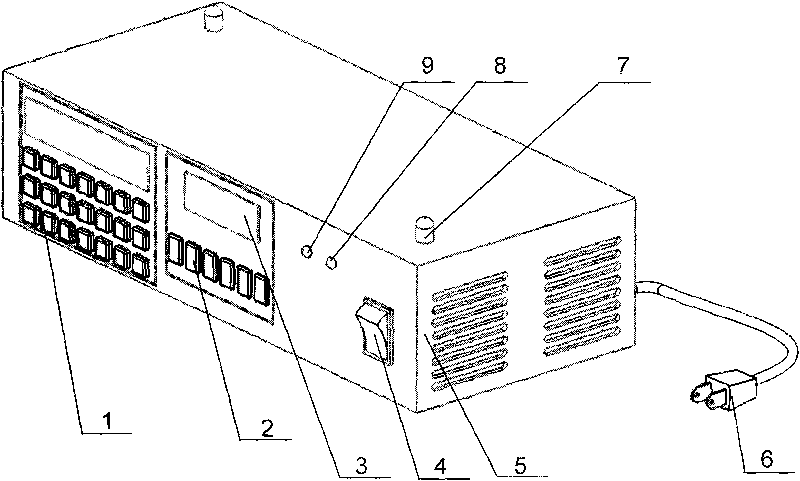

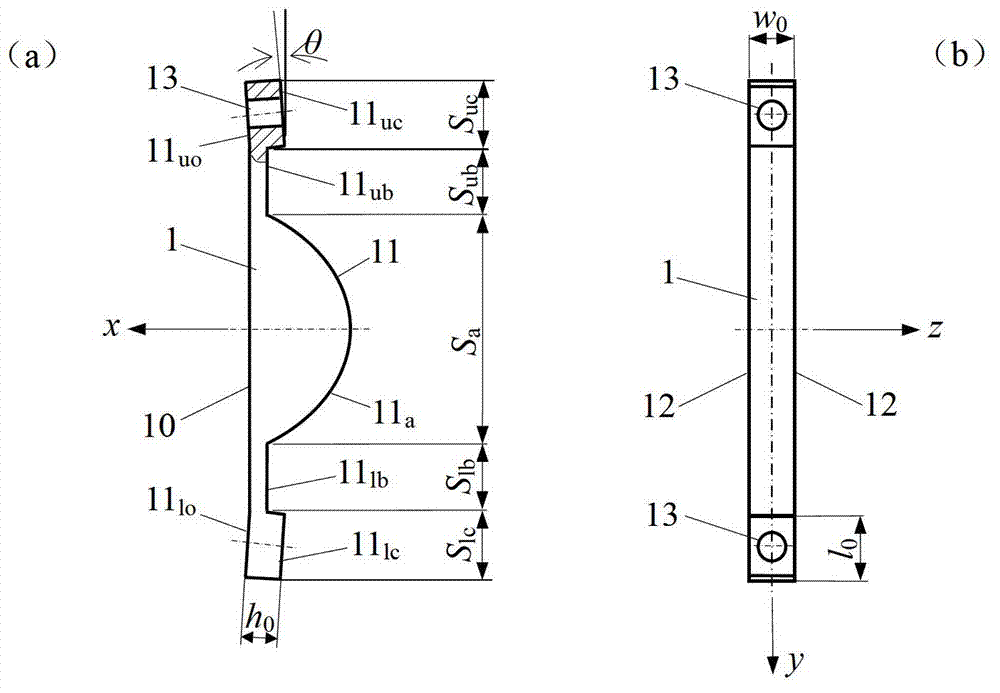

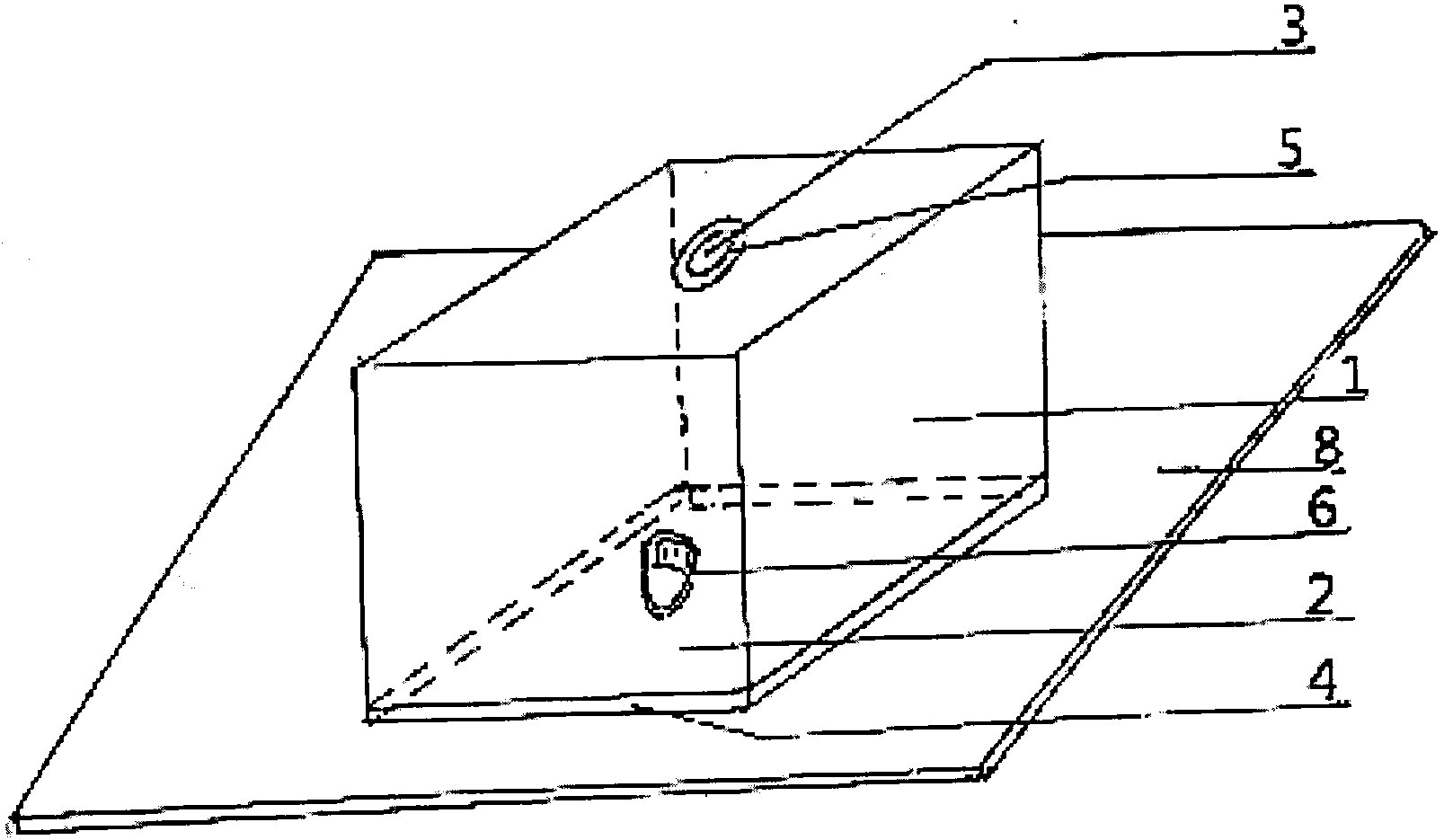

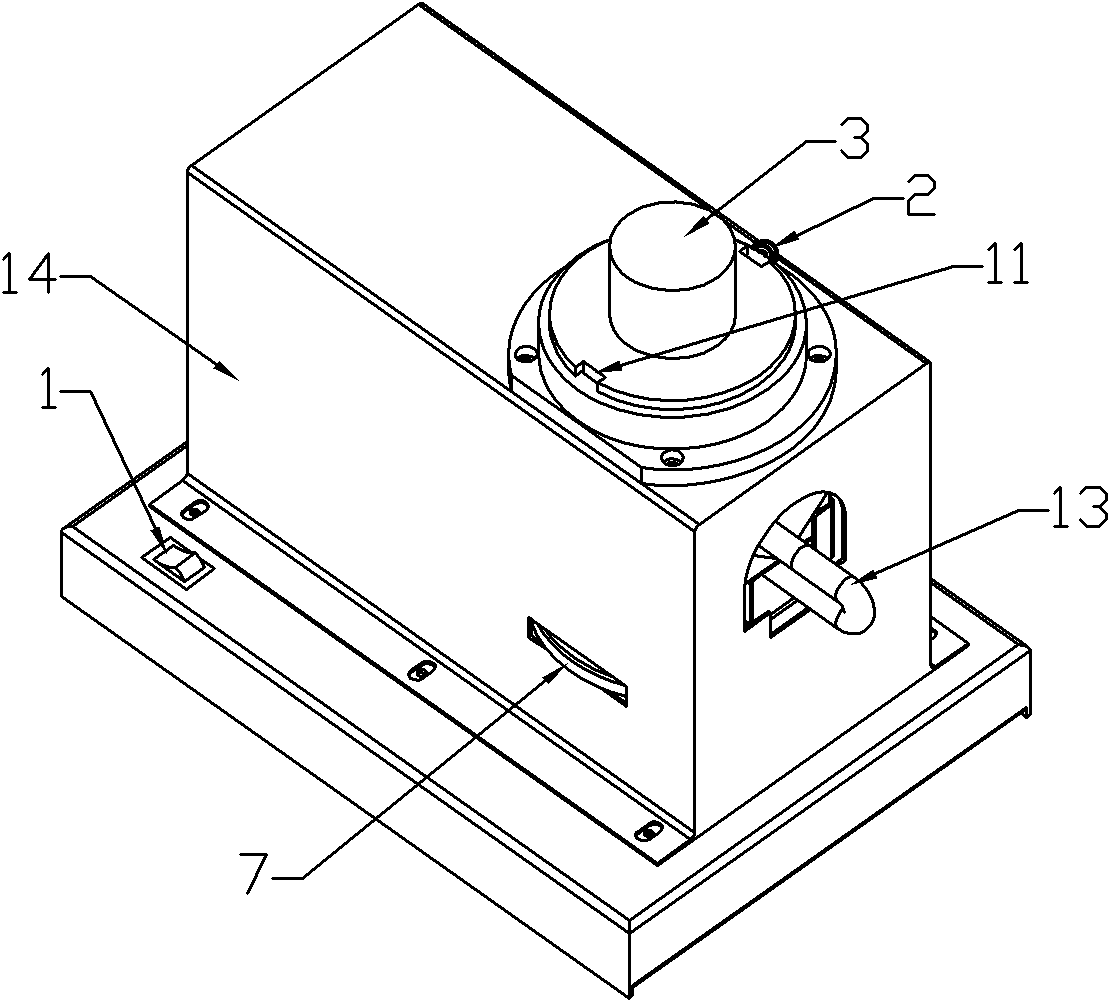

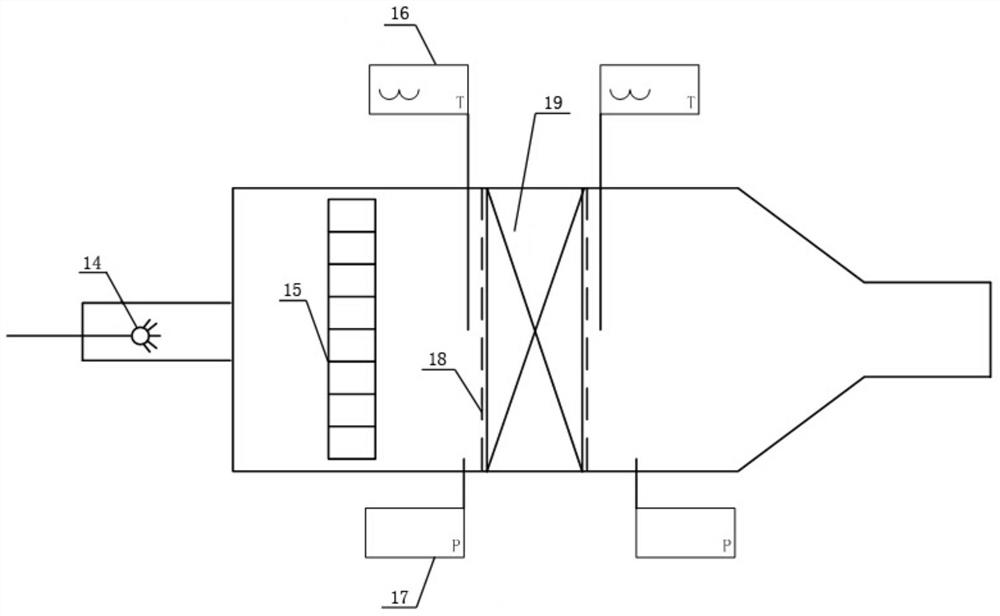

Device and method for measurement of light passing surface normal of electro-optic crystal and optical axis of electro-optic crystal

ActiveCN107505121AGood data repeatabilityRealize non-contact non-destructive testingGeometric properties/aberration measurementPhysicsOptical path

The present invention provides a device and method for measurement of a light passing surface normal of an electro-optic crystal and an optical axis of an electro-optic crystal. The main components of the device comprise: a linear polarized light laser, a first lens, a small aperture diaphragm, a second lens, a spectroscope, a plane mirror, a receiving screen, a third lens, a one-dimensional precision electric displacement stand, a fourth lens, a linear polaroid, a fifth lens, an image detector and a computer, and a photoelectric autocollimator and a sheet of parallel plate glass with 1'' of depth of parallelism are required for installation and regulation of a light path, etc. The device and method for measurement of the light passing surface normal of the electro-optic crystal and the optical axis of the electro-optic crystal realize non-contact nondestructive detection of the electro-optic crystal to be detected so as to overcome a series of problems that a crystal is easy to generate scratches, a measurement device is difficult to build and a conoscopic interference pattern is difficult to analyze in the current method. The third lens and the fourth lens change different F numbers to perform measurement of electro-optic crystals with different thicknesses. The data repeatability of measurement is good, and compared to the measurement data of a current X-ray crystal direction finder, the relative error is within 30''.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

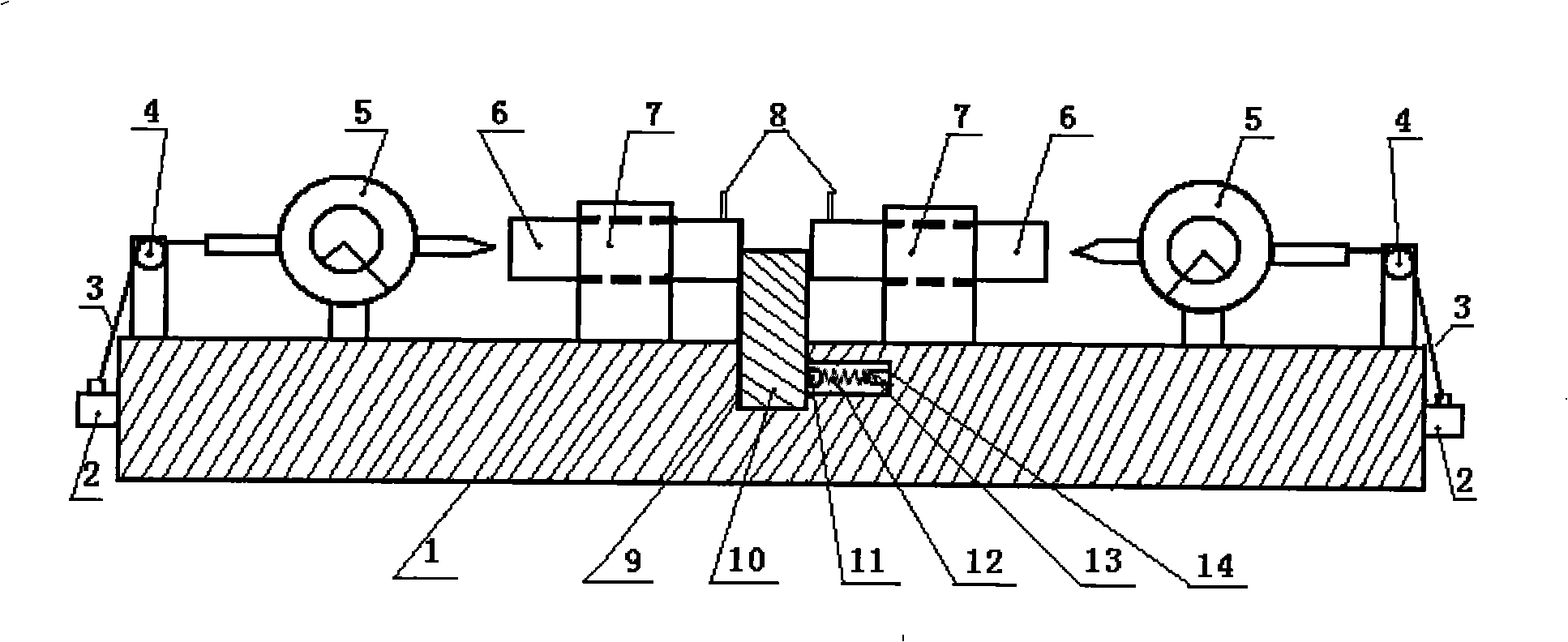

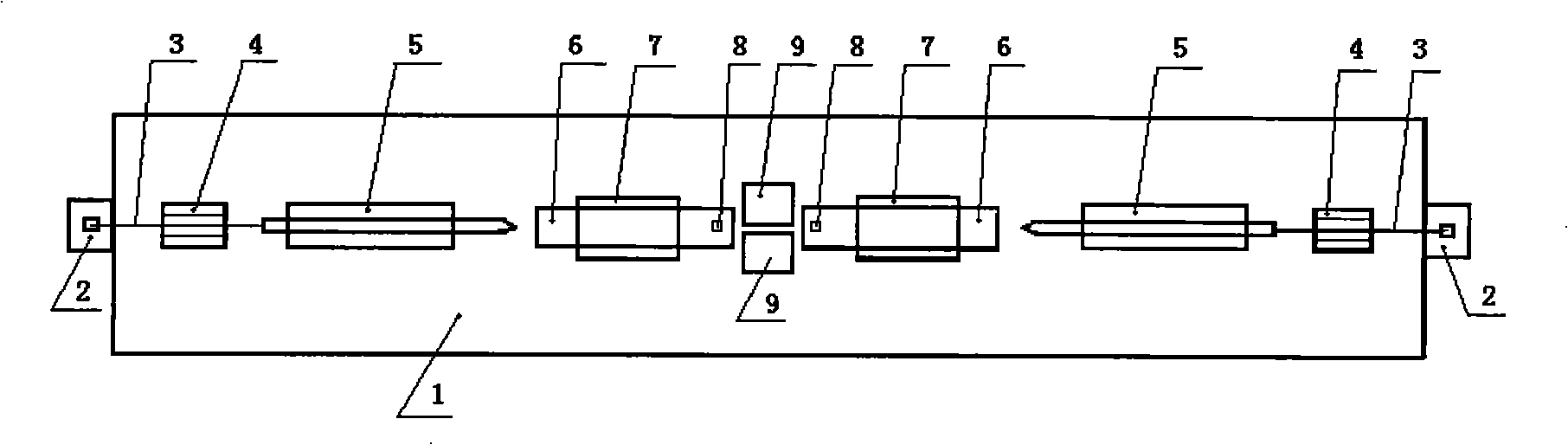

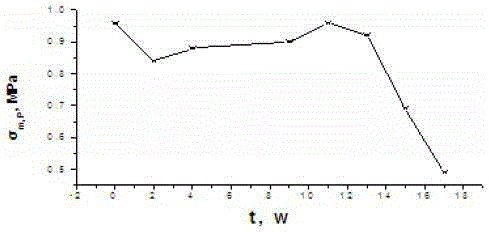

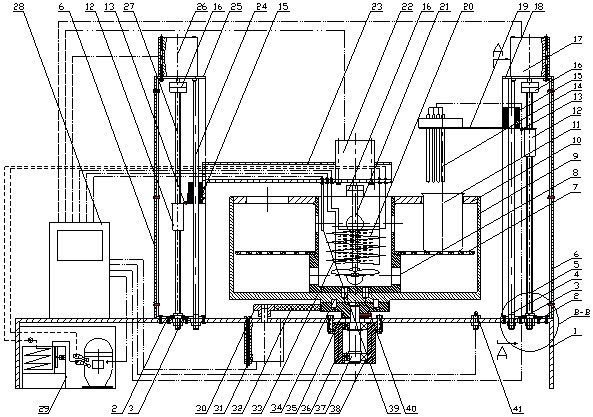

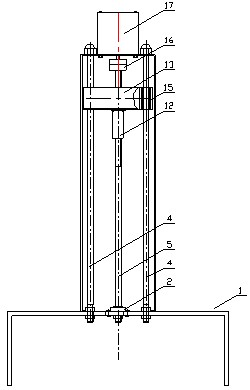

Left-right turning screw rod stretcher specially used in metallic plastic deformation and recrystallization test

InactiveCN101738353AEasy clampingCultivate PLC programming abilityFlow propertiesTesting metalsTurn angleBall screw

The invention provides a left-right turning screw rod stretcher specially used in a metallic plastic deformation and recrystallization test. The stretcher comprises an electric appliance control part, a screw rod transmission part, a mechanic transmission part and an aluminum sheet clamp part, wherein by the rotation of a left-right turning ball screw rod in the screw rod transmission part, a sample, of which both ends are tightly clamped, is outward stretched from the left and the right sides at the same time, and the stretching force is kept stable and uniform during stretching; the stretching size can be controlled to the micrometer level by the accurate step pitch turning angle of a stepper motor, so that the stretching in different deformation degrees can be realized according to the test requirements; and simultaneously, an assembled displacement ranging rod is connected with a working table of the clamp, so that the stretching distance can be quite accurately measured and displayed, the deflection generated when the sample is stretched can be accurately shown, and the success ratio of the test is improved.

Owner:DONGHUA UNIV

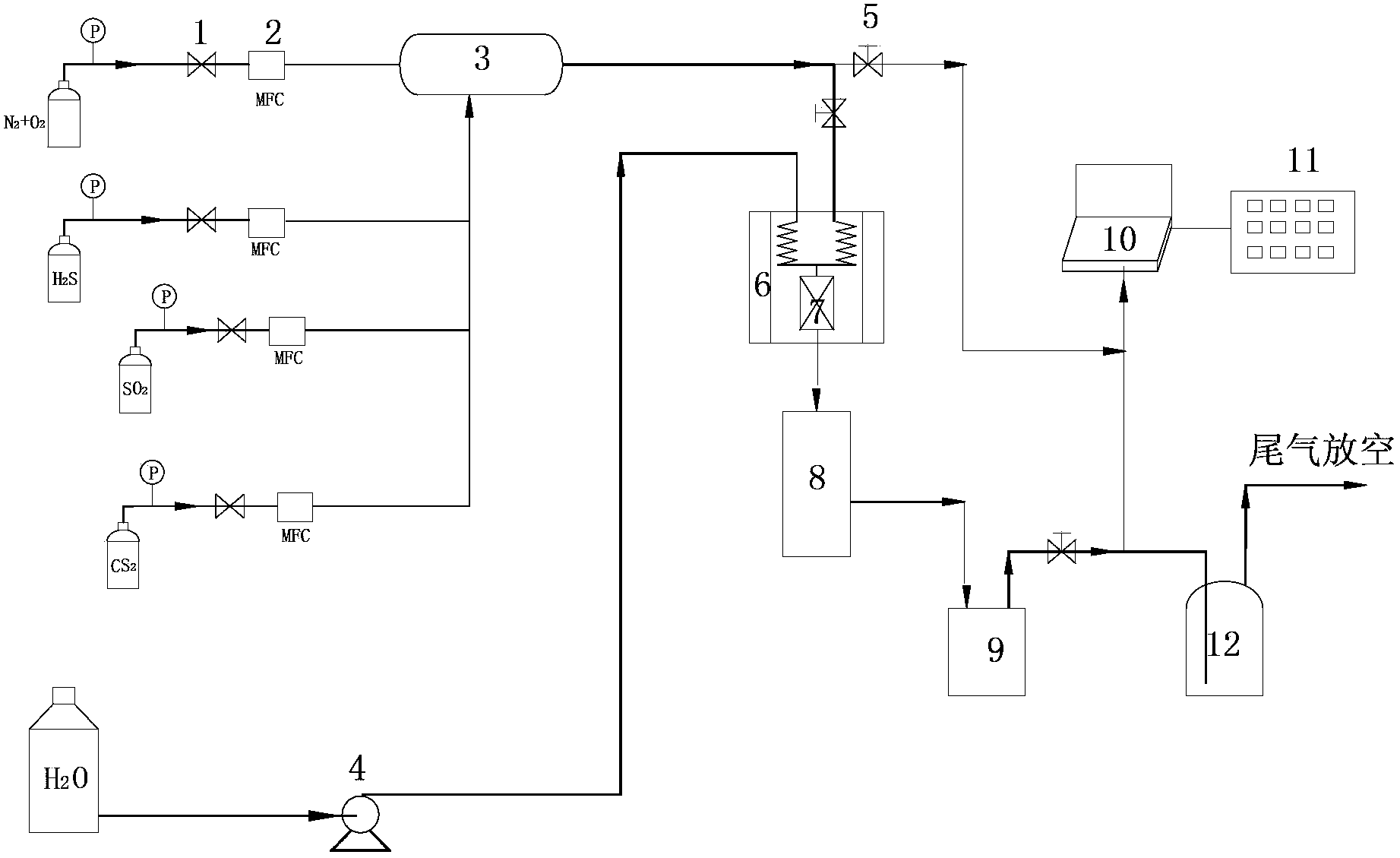

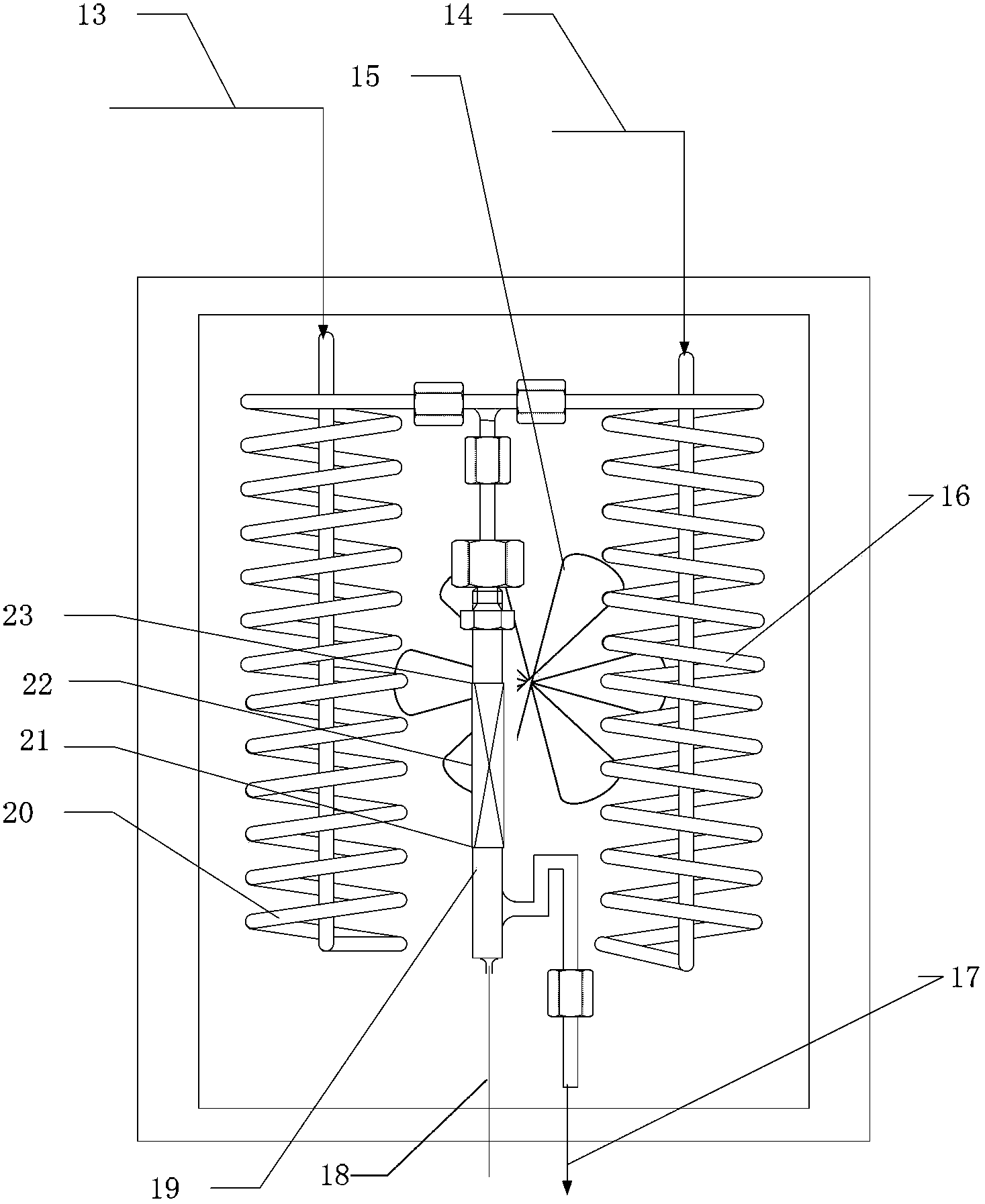

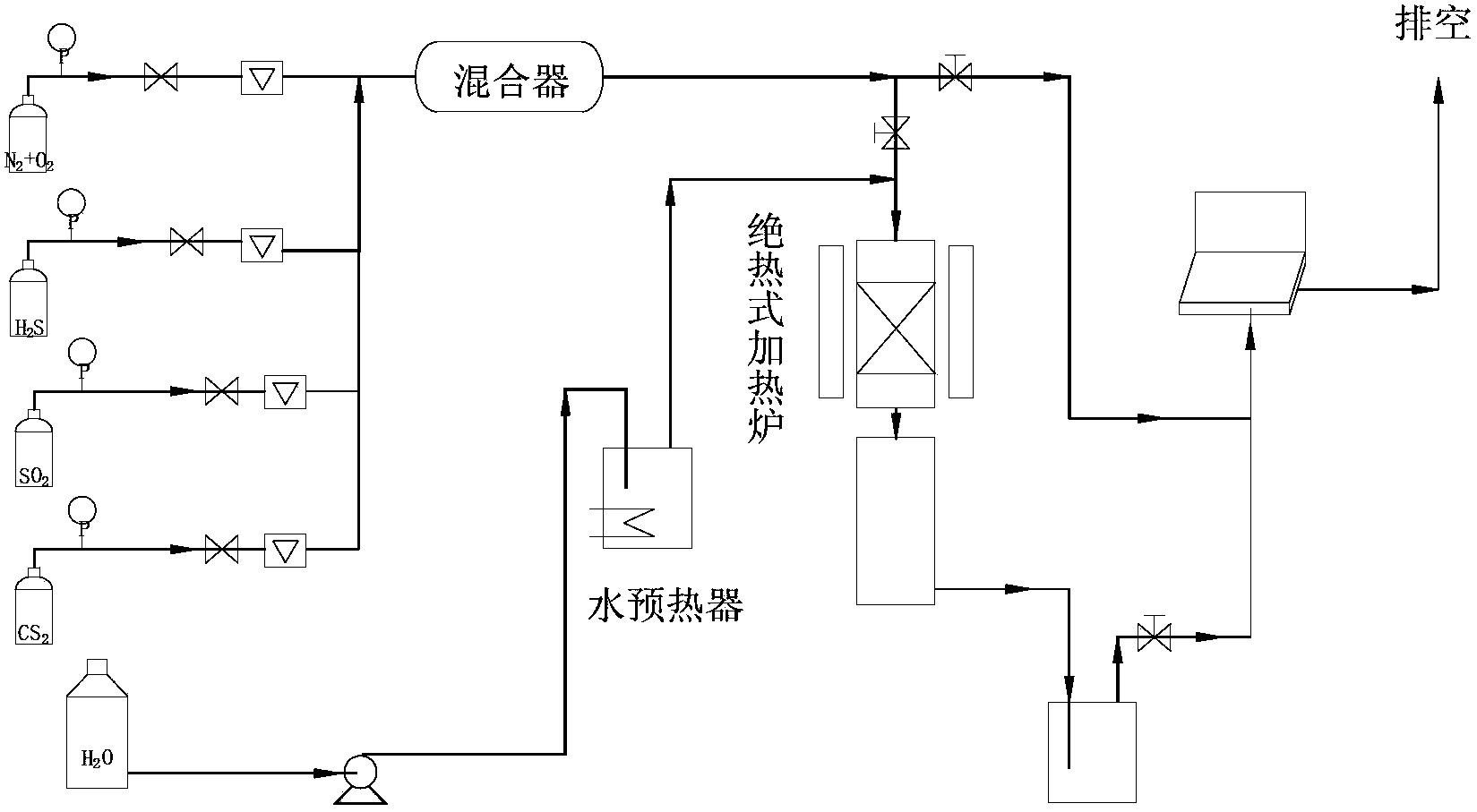

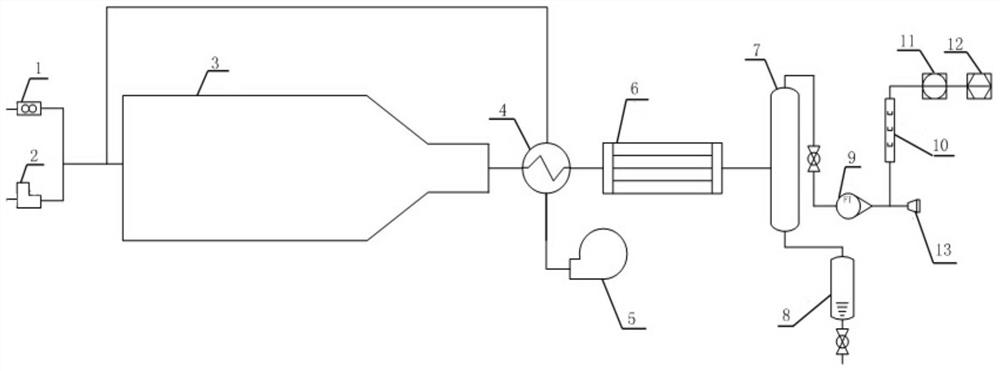

Sulfur recovery catalyst activity evaluating device and test method

ActiveCN103512966AGuaranteed uptimeSmall temperature differenceComponent separationElectricityComputer control system

The invention provides a sulfur recovery catalyst activity evaluating device and a test method, and belongs to the field of testing or analyzing a material by testing the chemical or physical property of the material. The device is characterized in that 1, a heat insulation type electric heating furnace is replaced by a blowing-type constant-temperature electric heating case (6), a reactor (7) is arranged in the blowing-type constant-temperature electric heating case (6); 2, a water pre-heater is saved, the distilled water after being measured is directly gasified in a water gasifying electric heating pre-heating coil (16) arranged in the blowing-type constant-temperature electric heating case (6); 3, an alkali liquor absorbing tank (12) is added; and 4, a computer control system (11) is provided. The sulfur recovery catalyst activity evaluating device and the test method provided by the invention have the characteristics of safety and stability in running, low temperature difference of a catalyst bed layer of the reactor, constant reaction temperature, exact and reliable test data, good repeatability, safety and environmental protection and convenience in use.

Owner:CHINA PETROLEUM & CHEM CORP

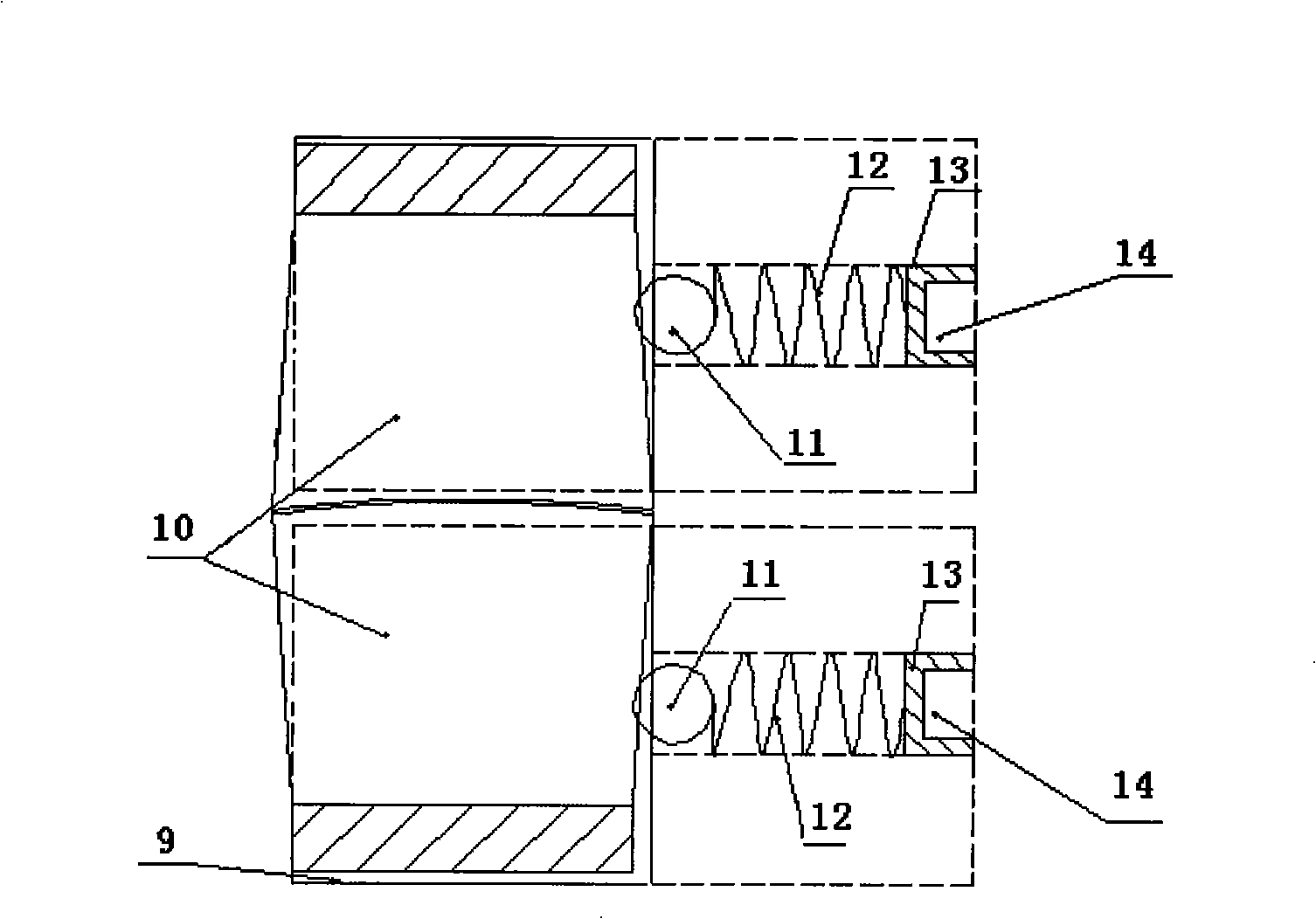

Device for measuring breaking- after lateral swelling capacity of impact test piece after irradiation

ActiveCN101329237AIncrease contactConvenient remote operationNuclear energy generationNuclear monitoringSwelling capacityMeasurement device

The invention discloses a measurement device used for measuring lateral expansion quantity of broken Charpy key hole specimen after radiation. The device of the invention comprises two heavy hammers, a pulley, an indicating gauge, a contact block, a guideway, a sample installation trough and a rolling trough. A compression spring in the indicating gauge is pulled away by the free drop of the heavy hammer so as to lead the ejector rod of the indicating gauge to be controlled under the traction of the heavy hammer; the guideway is internally provided with the sliding trough; the contact block can freely slide in the sliding trough; the broken sample is arranged inside the sample installation trough; the compression spring inside the rolling trough pushes a bump bead to tightly press the sample so as to lead two broken samples to be close to a benchmark surface and kept on the same plane; the compression spring of the indicating gauge is used for pushing the contact blocks to move face to face to tightly press the sample, thus ensuring good contact between the broken sample and the contact block. The measurement device of the invention used for measuring the lateral expansion quantity of the Charpy key hole specimen after radiation is simple and feasible, has high measurement precision, facilitates the remote operation by manipulators in a heat room, and greatly reduces the working quantity and labour intensity of the working personnel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

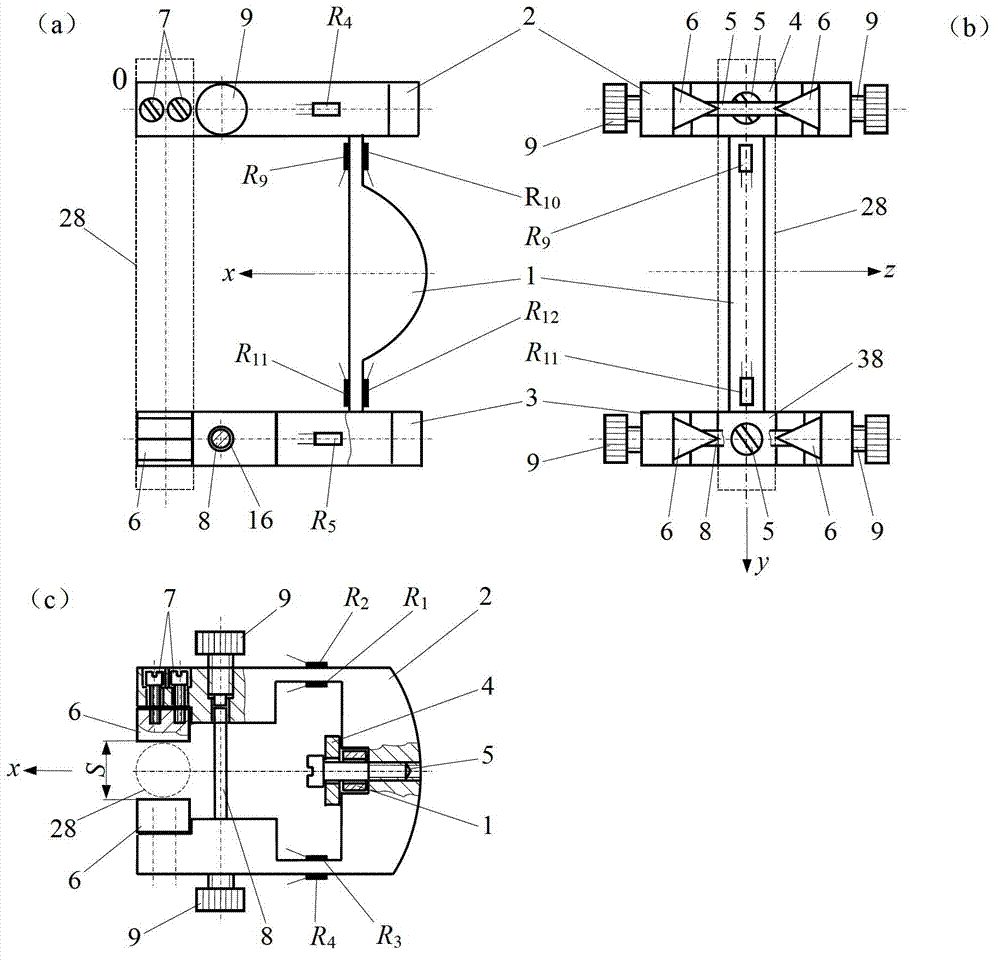

Resistance strain type eccentric-eliminating extensometer and use method thereof

ActiveCN102735539AEliminates the step of measuring the original diameter of the specimenOmit the original diameter stepElectrical/magnetic solid deformation measurementElectrical/magnetic diameter measurementsElectrical resistance and conductanceElastomer

The invention discloses a resistance strain type eccentric-eliminating extensometer and a use method thereof. The extensometer comprises a three-U-shaped sensor, an auxiliary locating plate and a standard, wherein the three-U-shaped sensor is characterized in that two U-shaped elastomers with clamping cutter points and resistance strain gauges form two independent radial extension sensors; the two independent radial extension sensors and an elastic beam with the resistance strain gauges form a U-shaped eccentric-eliminating axial extension sensor; and the standard is used for calibrating the radial extension sensors. The use method for the extensometer comprises the following steps of: setting the original gauge length of the axial extension sensor by an auxiliary locating plate; installing the three-U-shaped sensor on a tested sample; respectively connecting the resistance strain gauges on the three elastic elements into the resistance strain gauge in a full-bridge mode; when the tested sample is under the axial load action, the axial extension sensor outputs an axial deformation signal in real time; and the two radial extension sensors output the diameter signals of two clamping sections in real time.

Owner:烟台新天地试验技术有限公司

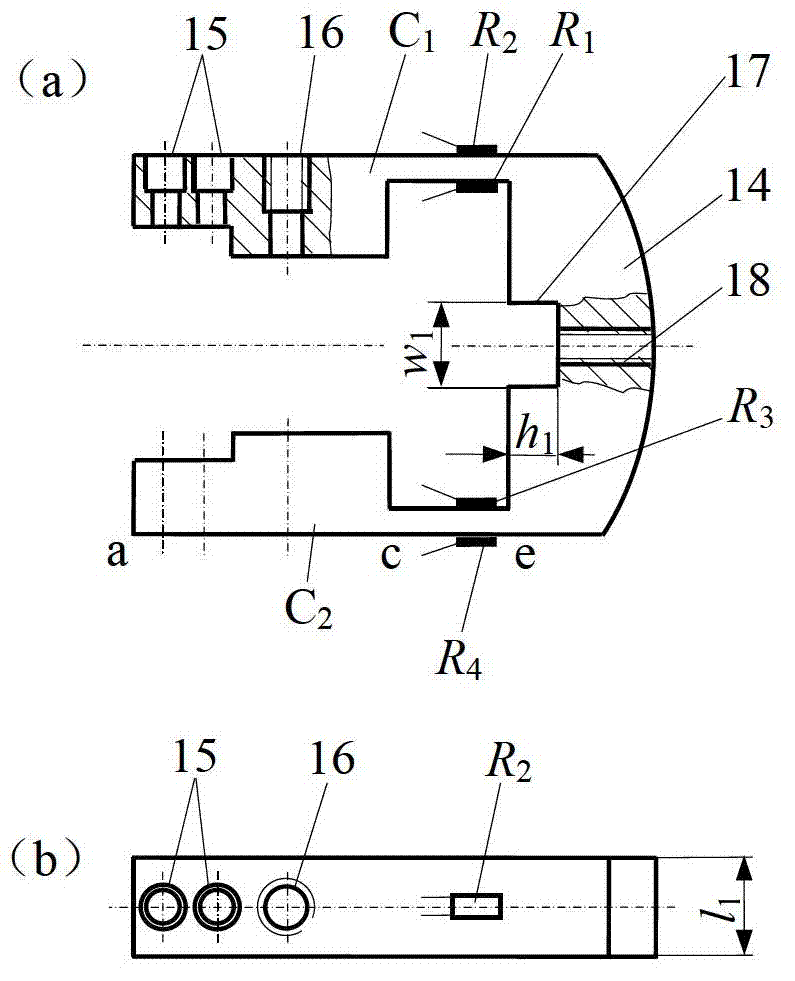

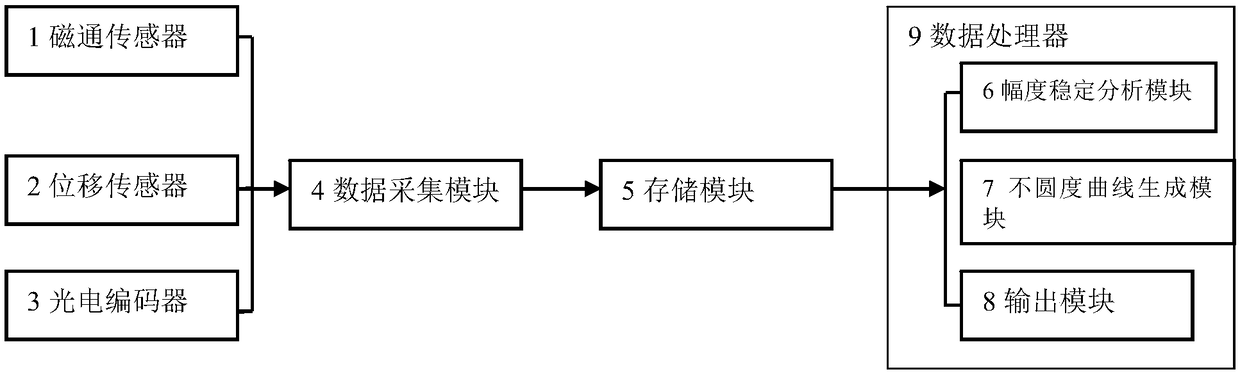

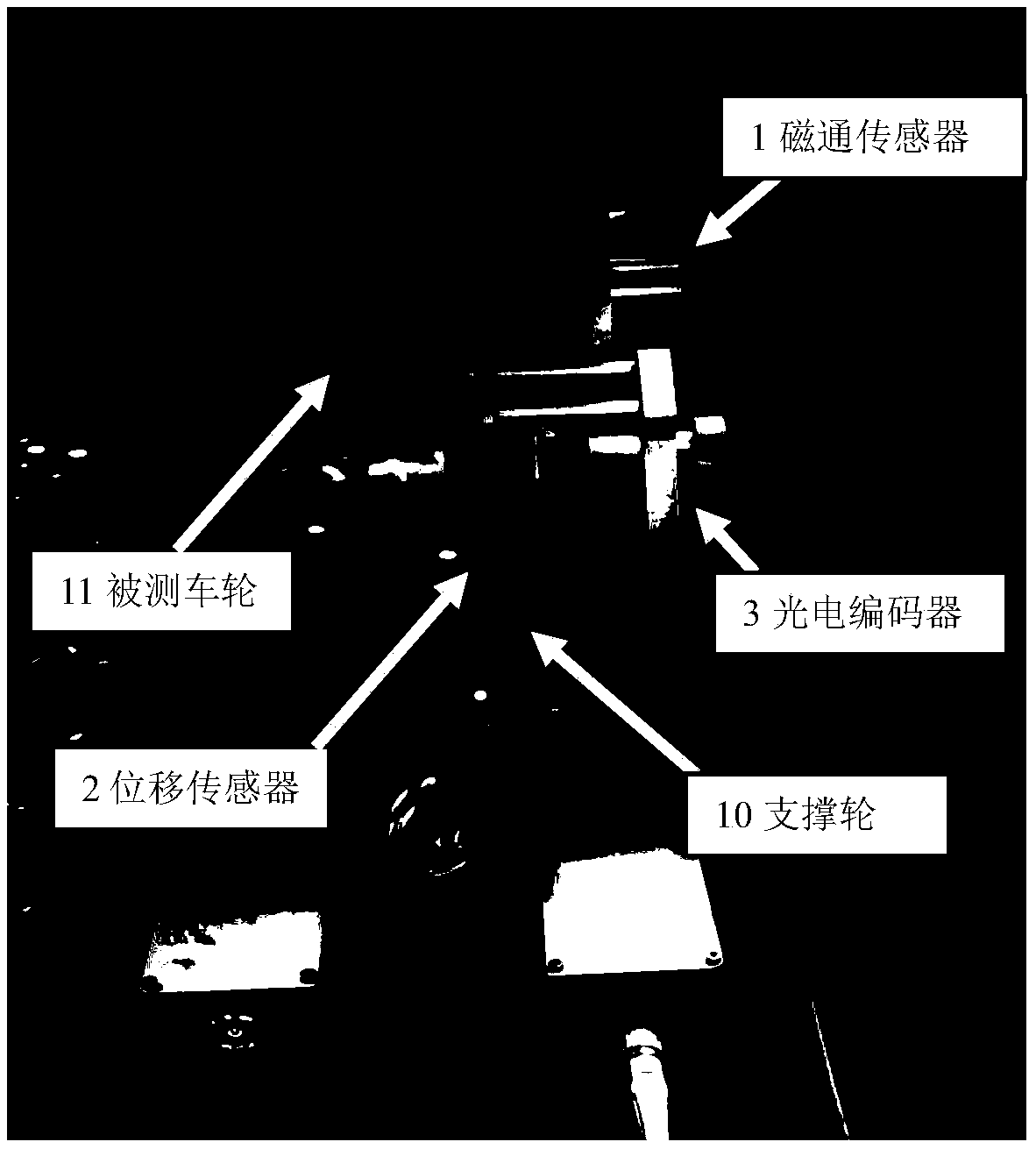

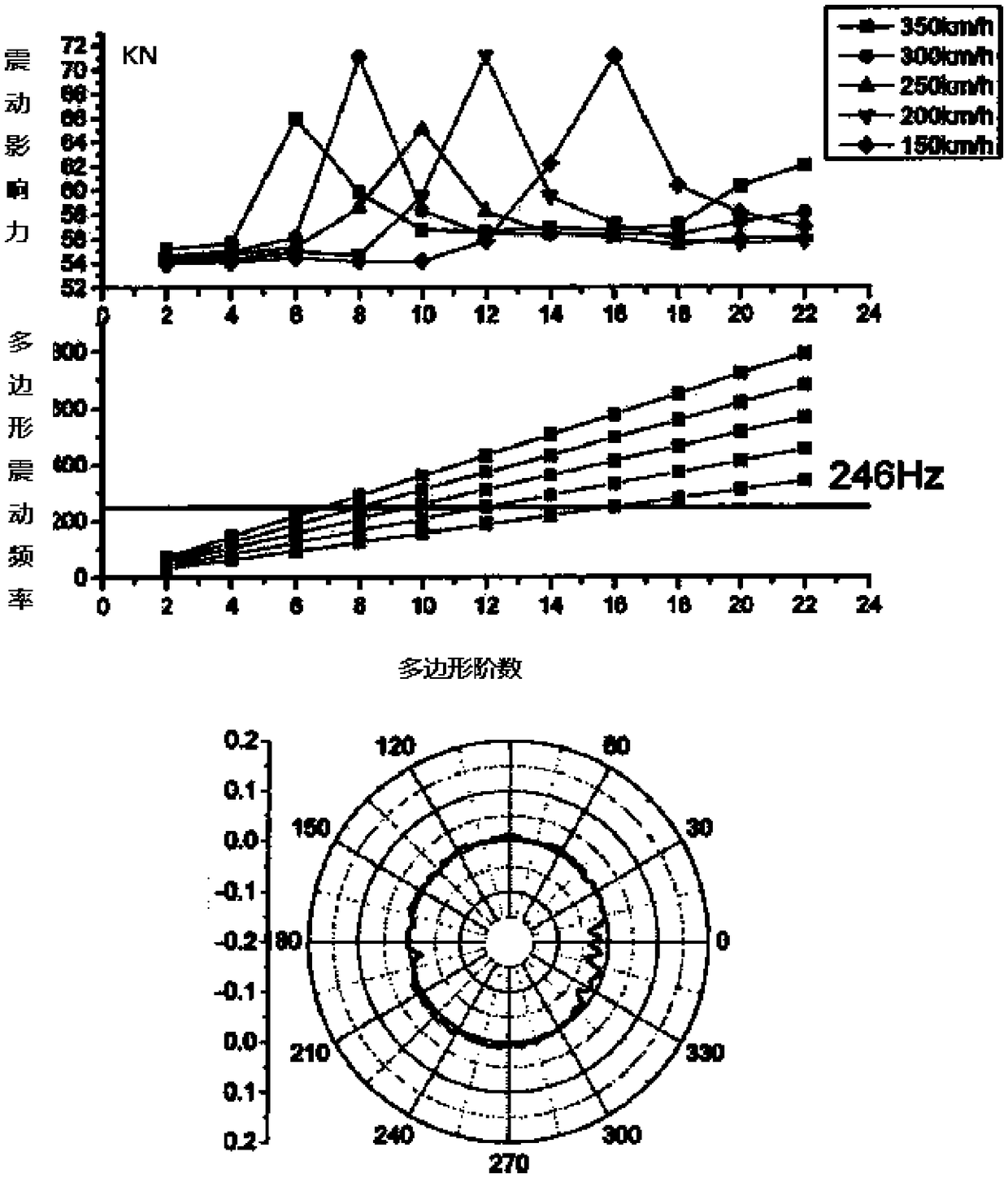

Wheel polygon test analysis method and system

ActiveCN109334708ACompact structureOverall small sizeWheel-rims surveying/measuringElectric/magnetic contours/curvatures measurementsTest analysisData acquisition

The invention provides a polygon test analysis system. The polygon test analysis system comprises a data acquisition module for collecting data and a data processor responsible for analyzing the datacollected by equipment and obtaining an out-of-roundness curve of a wheel to be tested. The wheel polygon test analysis system is provided with a storage module for storing the acquisition data. The data acquisition module and the data processor perform wired or wireless data transmission, and the data transmission mode is WIFI or USB line transmission. The wheel polygon test analysis system is provided with a power supply module, and a battery and / or a USB cable and / or a power source are used for power supply. The wheel polygon test analysis system is further provided with a display which candisplay the out-of-roundness curve in real time. The polygon test analysis system can improve accuracy and efficiency, has good repeatability and has a low comprehensive cost.

Owner:北京声科测声学技术有限公司

Detection reagent for lipoprotein-associated phospholipase A2 and preparation method thereof

ActiveCN103063664AReduce manufacturing costImprove stabilityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsLipoprotein-associated phospholipase A2Chemistry

The invention discloses a detection reagent for lipoprotein-associated phospholipase A2 and a preparation method thereof. The preparation method is characterized by comprising the following steps: a, weighing, by weight, 0.2 to 0.6 part of 1-myristoyl-2-(4-nitrophenyl succinyl)phosphatidylcholine, 0.1 to 0.5 part of citric acid, 0.04 to 0.2 part of sodium 1-nonane sulfonate, 0.06 to 0.20 part of ethylene diamine tetraacetic acid and 0.03 to 0.09 part of vitamin E; and b, dissolving the above-mentioned ingredients in 100 parts by weight of purified water and adjusting the pH value of an obtained solution to 2.50 to 5.00 by using hydrochloric acid with a concentration of 5M so as to prepare the detection reagent for lipoprotein-associated phospholipase A2. The detection reagent provided by the invention has the advantages of low preparation cost, good stability, easy preservation, good data repeatability and high detection sensitivity.

Owner:ZYBIO INC

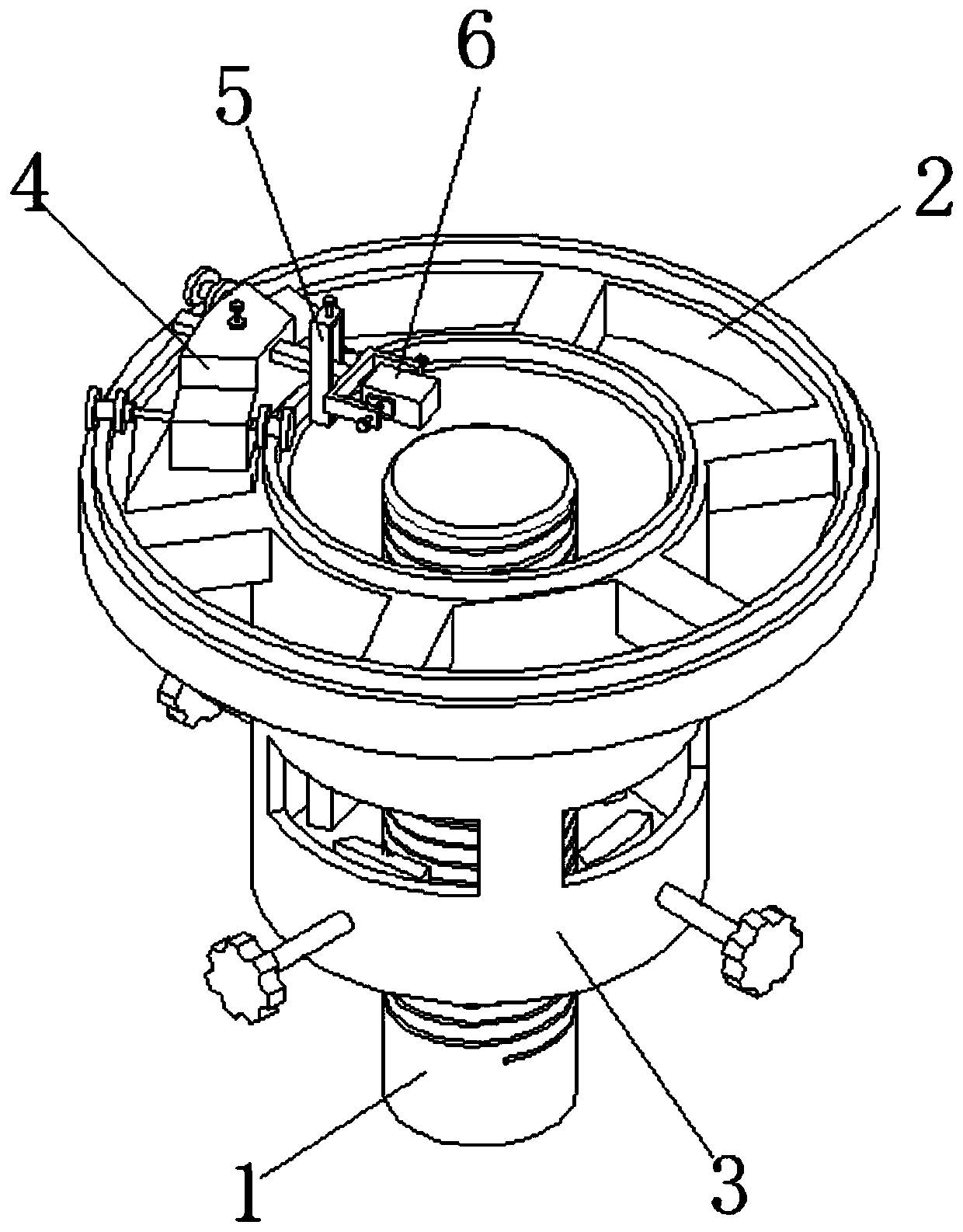

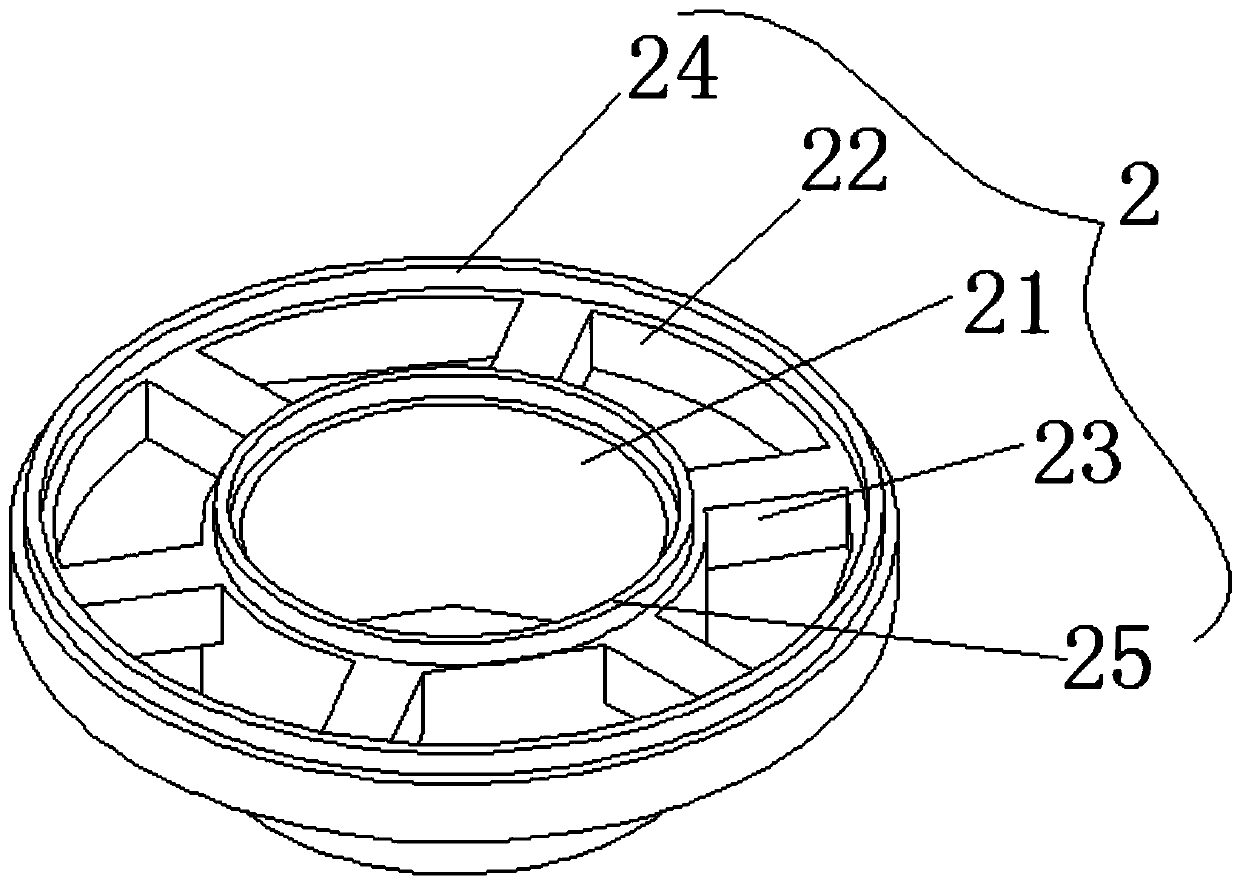

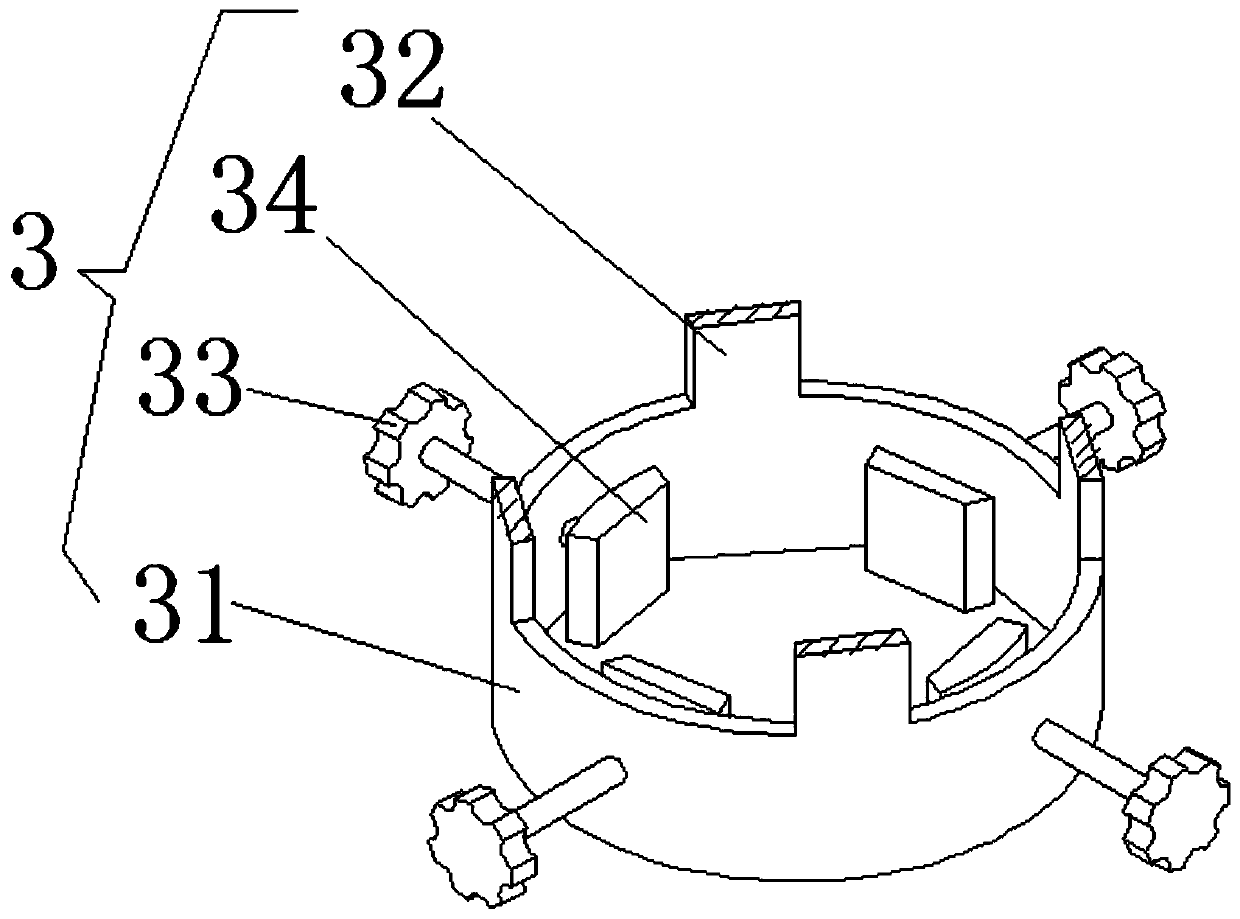

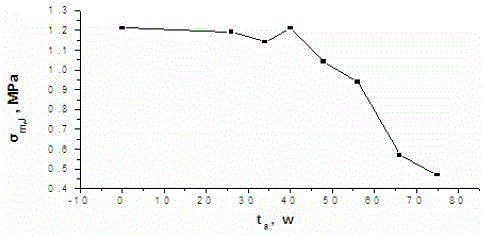

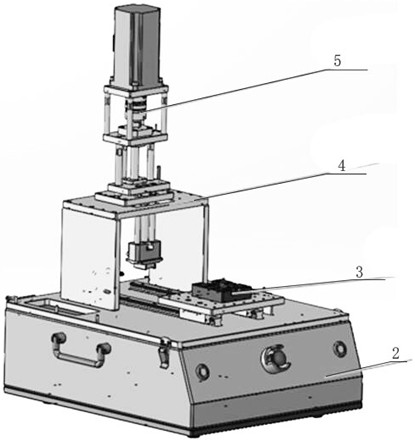

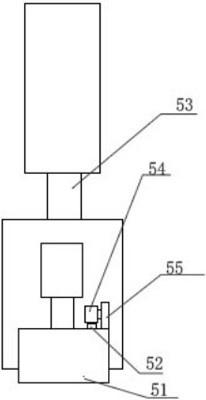

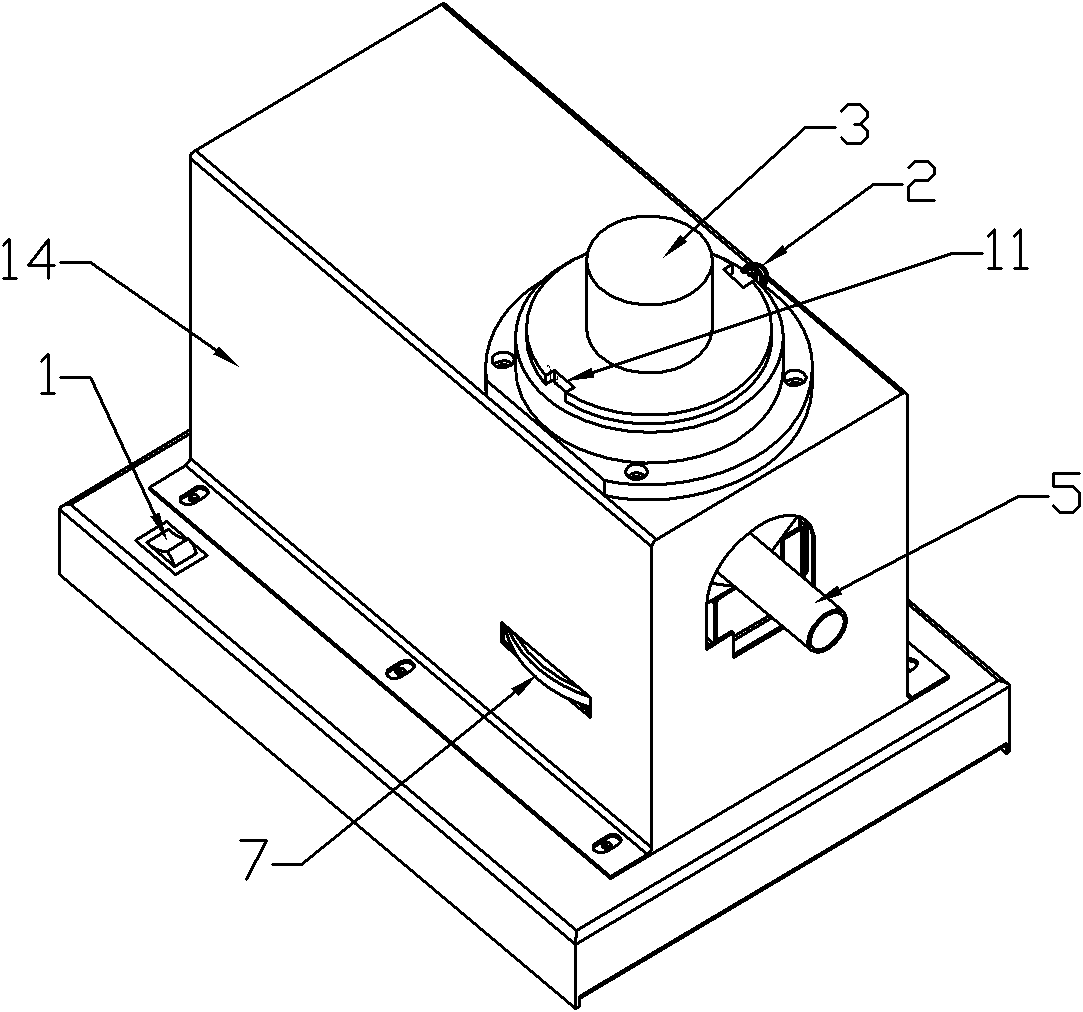

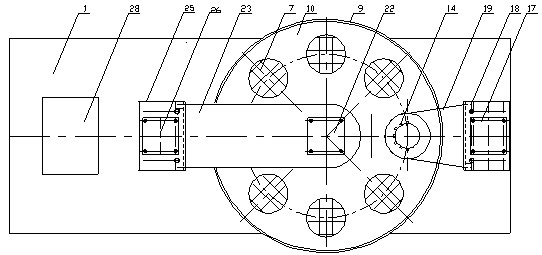

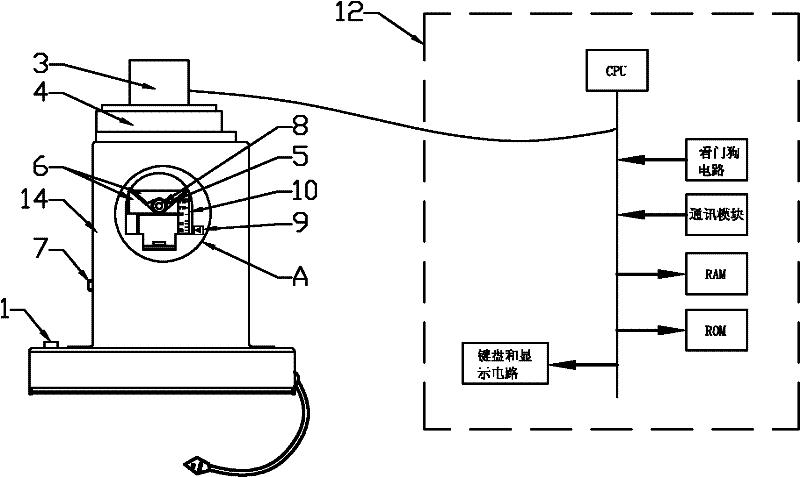

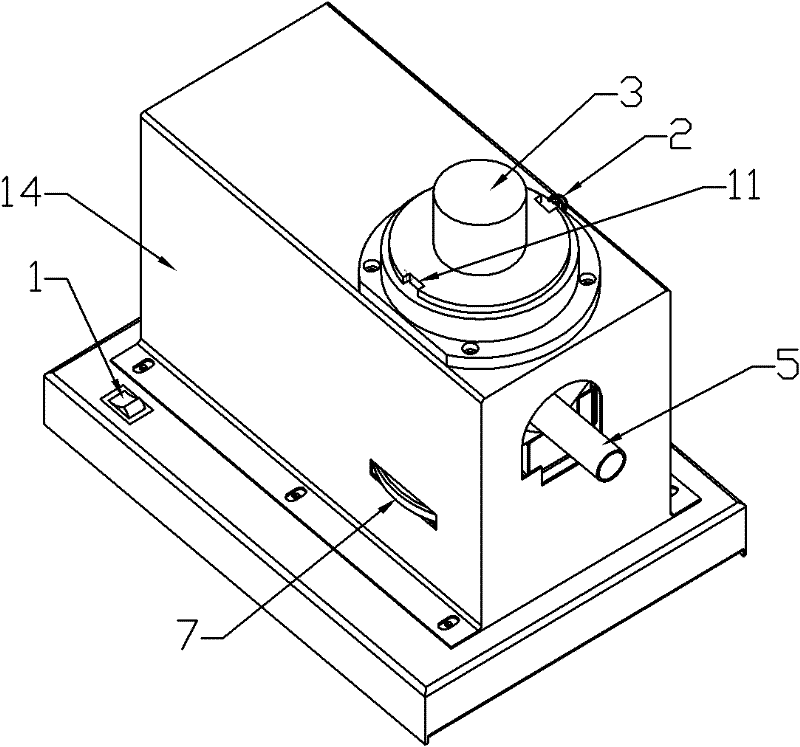

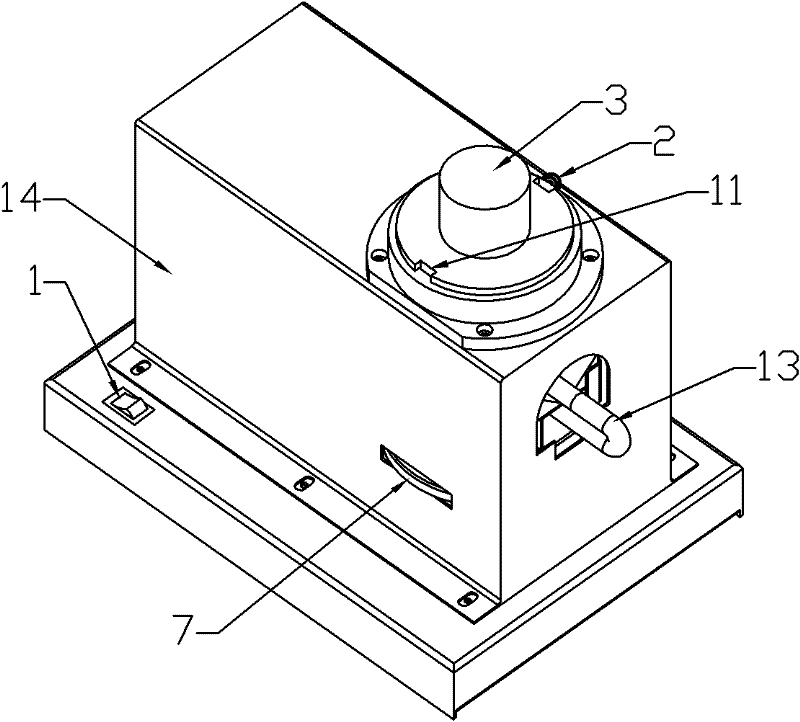

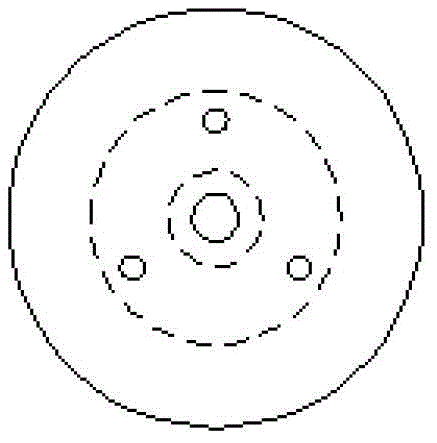

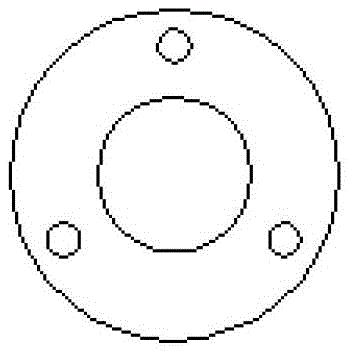

Bolt ultrasonic detecting method and device

PendingCN110118825AGood data repeatabilityImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesNondestructive testingUltrasound probe

The invention relates to the technical field of bolt non-destructive detecting, and specifically discloses a bolt ultrasonic detecting device.Thebolt ultrasonic detecting device comprises a bolt, anda guiding mechanism is arranged on the outer side of the top end of the bolt, the guiding mechanism comprises an inner rail frame and an outer rail frame, the inner rail frame and the outer rail frameare both of ring structures and are concentrically and parallelly distributed, a plurality of connecting rods are fixedly mounted between the inner rail frame and the outer rail frame, a first rail is mounted on the top of the inner rail frame, a second rail is fixedly mounted on the top end of the outer rail frame, a fixing mechanism is arranged at the bottom of the guiding mechanism,a sliding mechanism is arranged on the top of the guiding mechanism,a clamping mechanism is fixedly mounted on one side of the sliding mechanism, an ultrasonic probe is clamped on the clamping mechanism, and theultrasonic probe is located above the bolt. According to thebolt ultrasonic detecting device,the function of automatic detection is realized, data repeatability is good,detection precision is high, the position of the ultrasonic probe can be adjusted, thus the position of the ultrasonic probe is precisely controlled, and the detection precision is improved.

Owner:JIANGSU FRONTIER ELECTRIC TECH

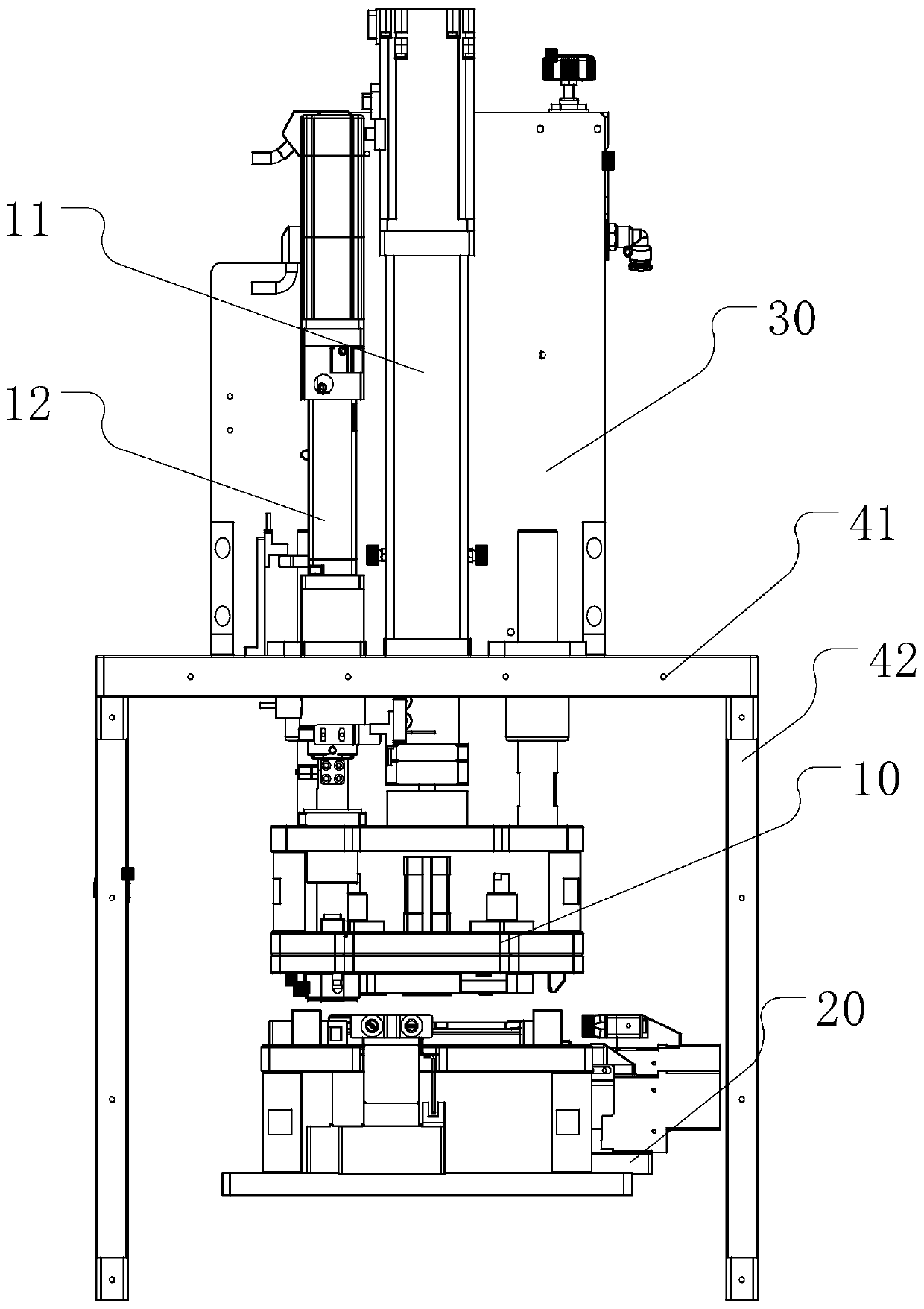

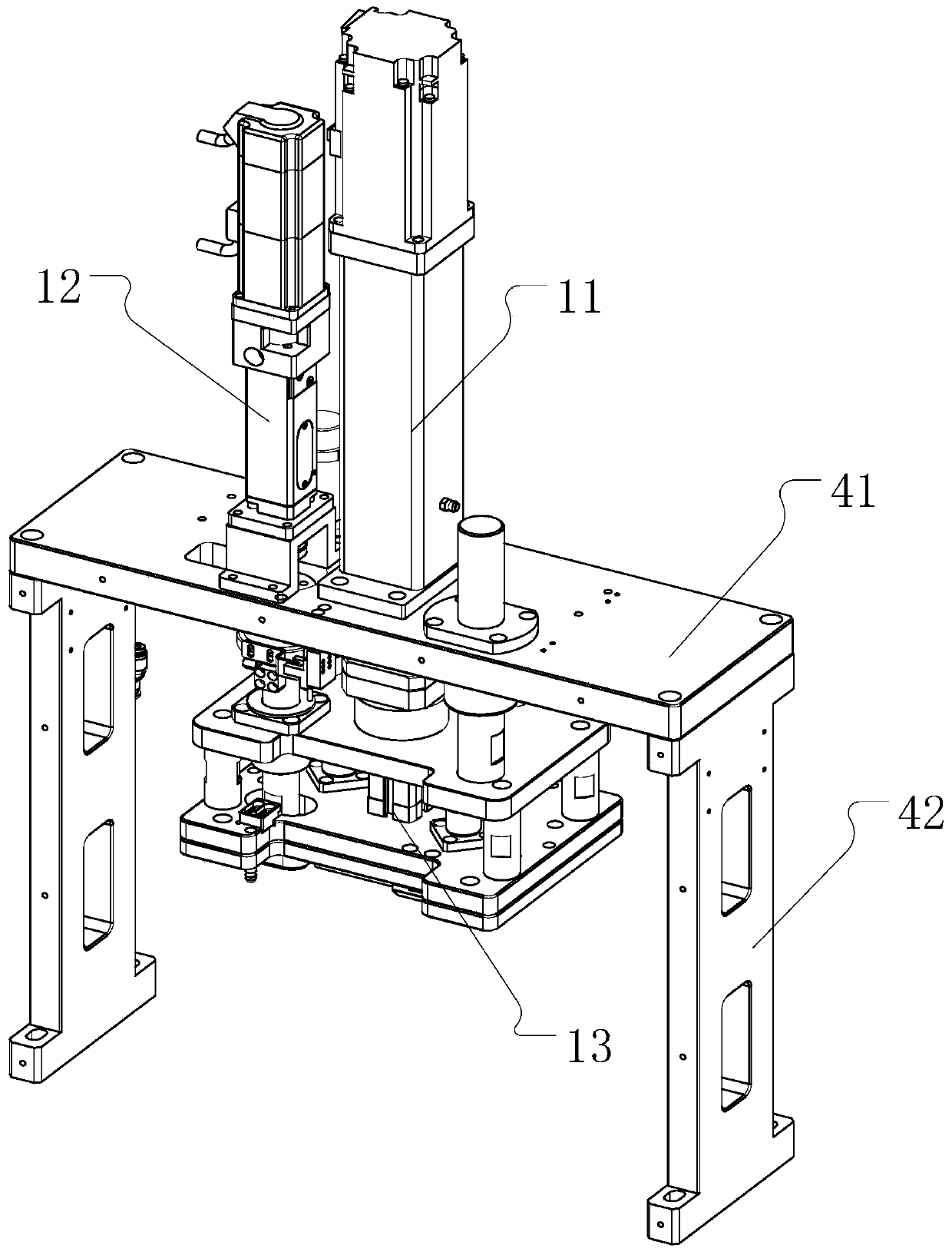

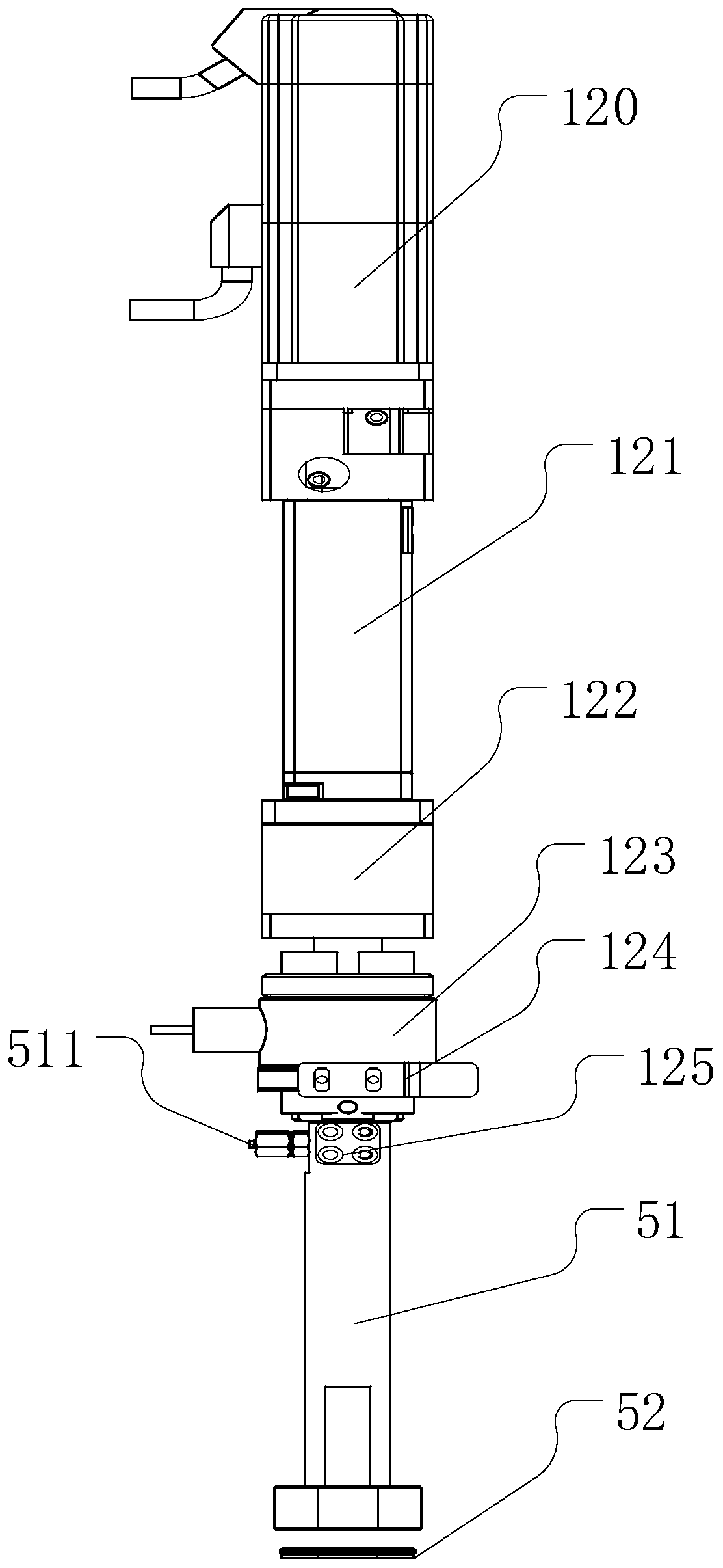

Airtightness test device and method

ActiveCN110132504AImprove test efficiencyRealize visualizationMeasurement of fluid loss/gain rateTest efficiencySoftware engineering

The invention provides an airtightness test device and method. The device comprises an air pressure test assembly, an upper die and a lower die which is arranged opposite to the upper die. The airtightness test device provided by the invention can carry out positive and negative air pressure airtightness tests, and realize the visualization of test results. The upper die and the lower die are aligned in real time, so that high test accuracy and relatively high data repeatability and relevance are achieved. A sealing assembly is in contact with a component to be tested, so that damage to the appearance of the component to be tested is reduced. The sealing assembly can be disassembled and replaced rapidly, so that the test efficiency of the test device is improved. A multi-power sealing structure is used for sealing step by step, so that stress on the component to be tested is reduced, and the process problem in the component to be tested can be debugged and analyzed. A pre-pressing function is realized, so that the stability of airtightness data can be improved effectively.

Owner:HANS LASER TECH IND GRP CO LTD +1

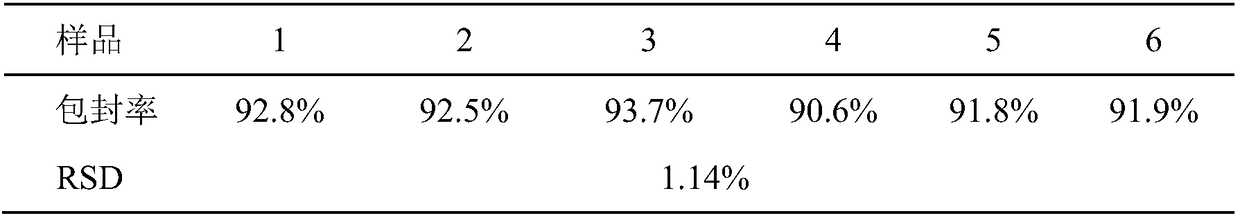

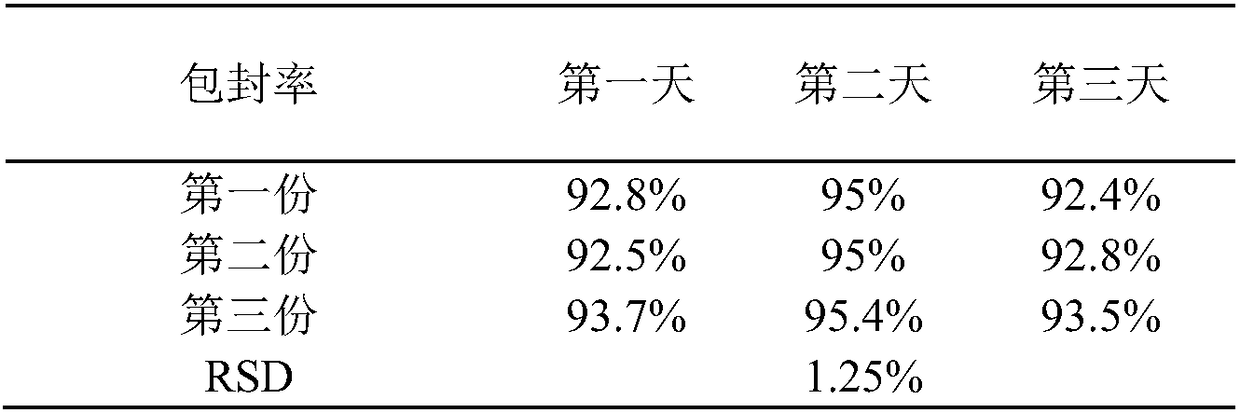

Detection method for encapsulation rate of propofol medium/long chain fat emulsion injection

InactiveCN108254450AEffectively distinguish the encapsulation stateEasy to operateComponent separationUltrafiltrationCentrifugation

The invention provides a method for determining the encapsulation rate of propofol medium / long chain fat emulsion injection. The method provided by the invention combines ultrafiltration centrifugation and high performance liquid chromatography detection to determine the encapsulation rate of propofol medium / long chain fat emulsion injection, and is especially suitable for propofol medium / long chain fat emulsion injection. The method also has the advantages of good reproducibility, good accuracy, verifiability, short time and low experiment cost, and can reflect the actual encapsulation condition of propofol medium / long chain fat emulsion injection more truly and accurately.

Owner:SHANGAI PHARMA GRP CO LTD

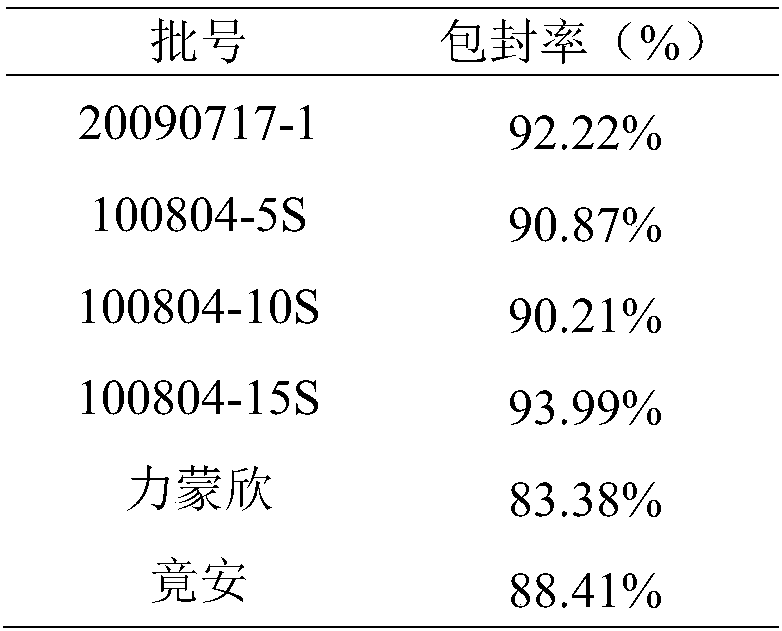

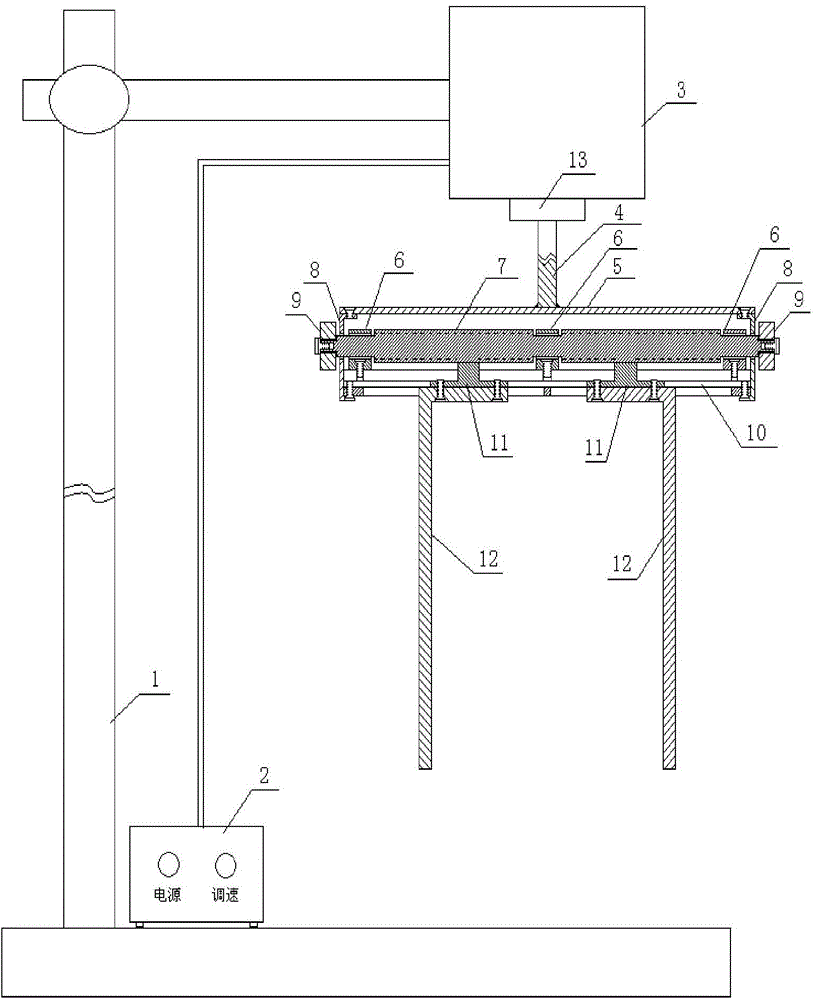

Adjustable n-shaped mixer

The invention relates to an adjustable n-shaped mixer. The mixer is in an n shape. A motor connecting shaft which is connected with a motor is arranged on the upper portion of the mixer. A cuboid screw type mixing blade adjuster is welded to the lower end of the motor connecting shaft. Tooth sliding blocks which are located in a slideway and engaged with the slideway are pushed by rotating a screw, so that mixing blades fixed to the lower portions of the tooth sliding blocks are driven, and the distance between the two mixing blades is adjusted to be adapted to different cylindrical containers. Each mixing blade is in the shape of an inverted L, and in order to improve the mixing effect, the included angle between the transverse direction of the mixing part of each mixing blade and the tangent line of a rotating arc of the mixing part of the mixing blade is 35 degrees. The purpose of even mixing is achieved through revolution of the mixing blades and a lower revolution speed, and thus side effects of mechanical shearing on a polymer solution are reduced to the maximum extent in the preparation process. The adjustable n-shaped mixer is mainly used for stirring in the indoor polymer solution preparation process.

Owner:PETROCHINA CO LTD

Group biotoxicity detection method

InactiveCN104897653AAvoid interferenceEasy to testChemiluminescene/bioluminescenceBiological testingMeasuring instrumentUltraviolet

The invention discloses a group biotoxicity detection method and belongs to the field of a biological analysis and detection technology. According to the method, a specific biological bacterium is cultivated, benzoin dimethyl ether is used as a photoinitiator, and the biological bacterium is irradiated with ultraviolet rays to give out light; then, initial luminosity factor and post luminosity factor of the photogenic bacterium are measured by a photometric measuring instrument. The higher the luminosity factor is, the higher the toxicity detection ratio is. Thus, biotoxicity detection is realized. According to the invention, the biochemiluminescence toxicity detection method is invented in allusion to present technical defects, problems such as low toxicity detection rate, low work efficiency and the influence of strains are solved, and work efficiency and toxicity detection rate are raised. The detection method provided by the invention has characteristics of fast analysis speed, low cost, no influence of strains and the like.

Owner:CHANGZHOU UNIV

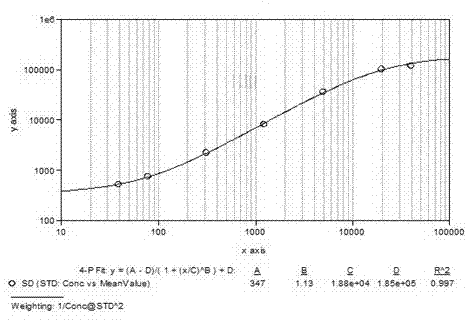

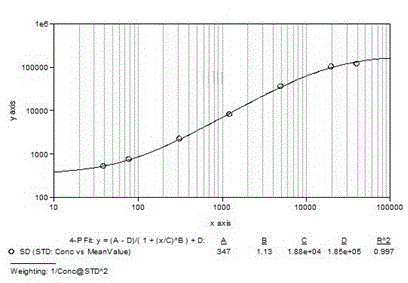

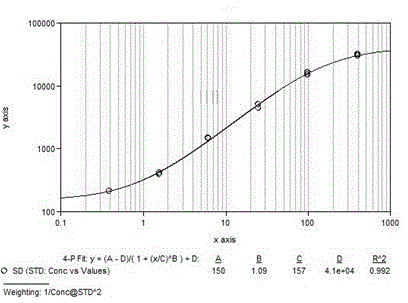

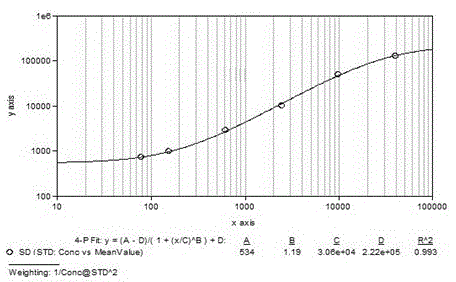

Kit for simultaneous detection of four depression markers and preparation method thereof

ActiveCN104749354AEasy to acceptImprove detection efficiencyBiological testingStatistical analysisImaging analysis

The invention relates to the technical field of immunodetection, and provides a kit for simultaneous detection of four depression markers and a preparation method thereof, the preparation method is as follows: antibody coating is prepared; enzyme label plates prepared in the first step are respectively poured, closed, washed, air-dried, and stored for standby use; a sample is loaded, the enzyme label plates are put into an incubation oscillator for incubation, then a detection antibody is added; enzyme SA HRP is added into plate holes for continuing incubation; CCD imager is used for filming and imaging, the image IDV value can be calculated by combination of image analysis software, according to the IDV value, a standard curve is drawn, and the sample concentration result is calculated; and softMax regression model and Excel table are used for calculation and statistical analysis of the sample concentration result. The preparation method solves effectively the problem of complicated process, operation disadvantage and low sensitivity.

Owner:LIGHTARRAY BIOTECH WUXI

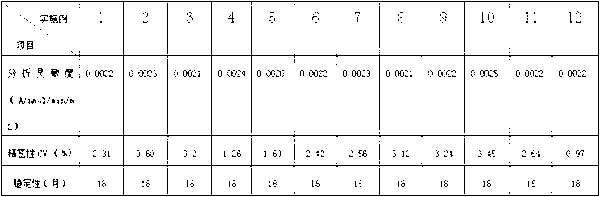

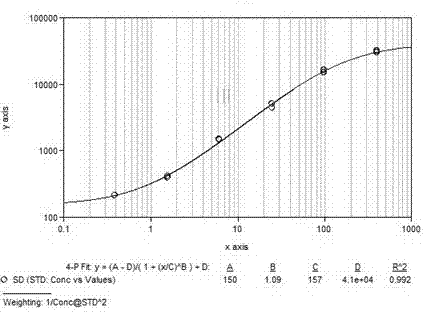

Chemiluminescent kit for simultaneously detecting four tumor markers and preparation method of chemiluminescent kit

InactiveCN103558384AEasy to acceptImprove detection efficiencyChemiluminescene/bioluminescenceBiotin-streptavidin complexStatistical analysis

The invention relates to the technical field of immune detection and provides a chemiluminescent kit for simultaneously detecting four tumor markers and a preparation method of the chemiluminescent kit. The preparation method comprises the following steps: preparing an antibody coating; respectively pouring, sealing, washing and airing an enzyme-linked immunosorbent assay (ELISA) plate in the first step, and storing the ELISA plate for later use; charging a sample, putting the ELISA plate into an incubation oscillator, and incubating an antibody; adding into kit streptavidin-horse radish peroxidase (SA-HRP); shooting an image through a charge coupled device (CCD) imager, and calculating an IDV value of the image through image analysis software; drawing a standard curve according to the IDV value, and calculating a sample concentration result; and performing calculation and statistical analysis on the sample concentration result by using a softMax regression model and an Excel form, and performing comprehensive analysis. By virtue of the chemiluminescent kit and the preparation method thereof, the problems of complicated process, inconvenience in operation and low sensitivity are effectively solved.

Owner:LIGHTARRAY BIOTECH WUXI

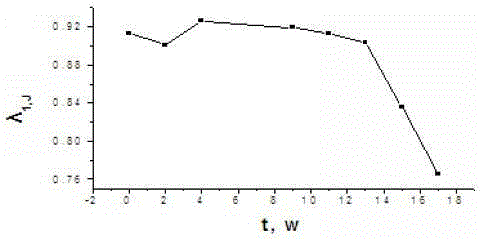

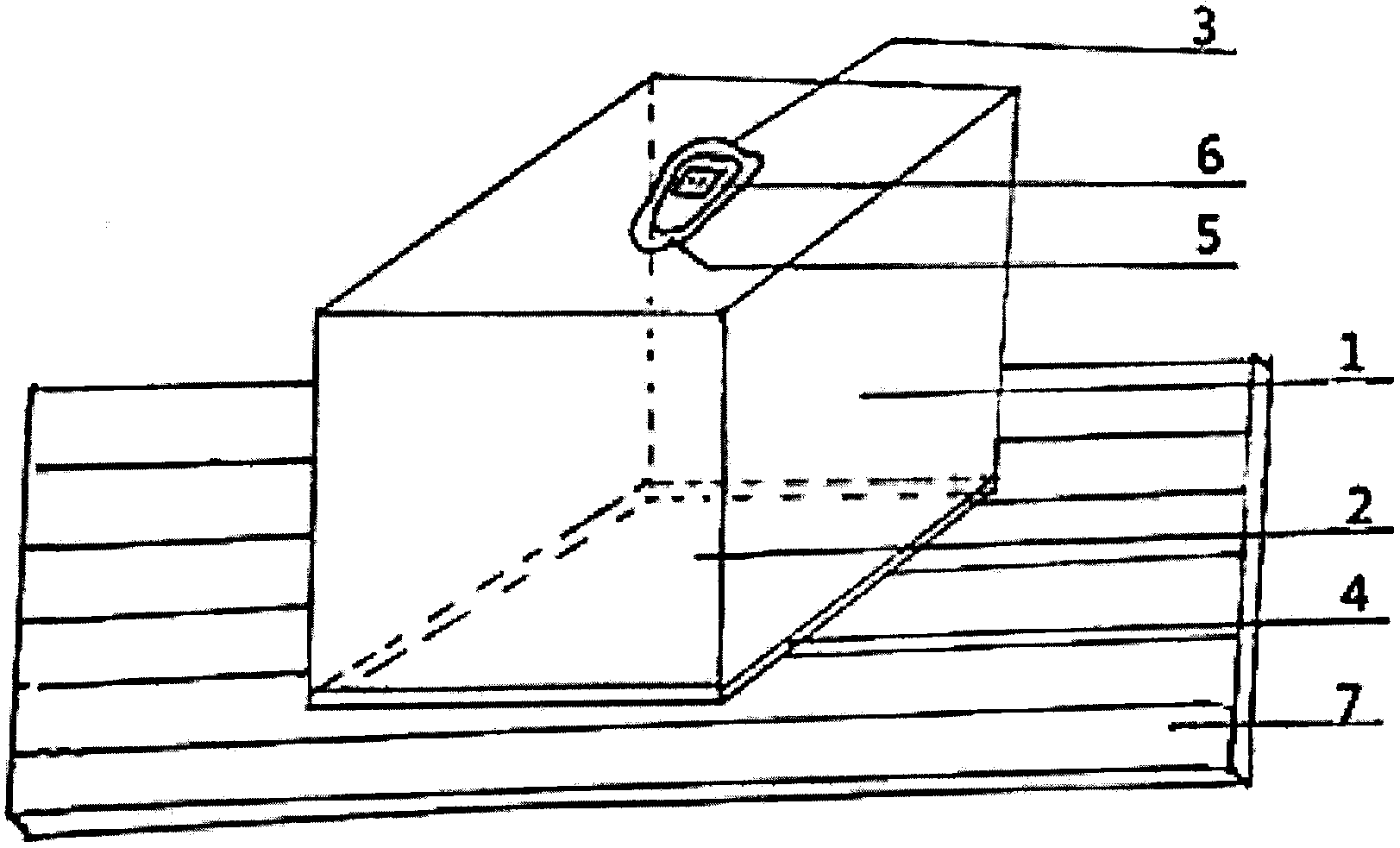

Non-destructive detection method of storage ageing performance of propellant/liner bonding interface

InactiveCN106338486AThe detection process is simpleGood data repeatabilityMaterial analysis by optical meansData processingData analysis

The invention relates to a nondestructive detection method of the storage ageing performance of a propellant / liner bonding interface, used for spaceflight fuel nondestructive detection. The method comprises the following steps: sample preparation and parameter detection, data analysis and mathematic modeling, and parameter calculation and data processing, wherein the sample preparation and parameter detection step comprises contrastive sample preparation and contrast parameter establishment which are used for macroscopic detection, and detection sample preparation and infrared spectrum detection which are used for microanalysis; infrared spectrogram analysis and establishment of a mathematical relationship are carried out in the data analysis and mathematic modeling step; and in the parameter calculation and data processing step, peak separation software of an infrared spectrometer is used to acquire data, and the data is substituted to the mathematical relationship, and parameter calculation is carried out to acquire a performance parameter. The method adopts a tiny amount sampling mode, infrared spectrum detection and mathematic modeling to realize spectrogram analysis and data processing in order to obtain the bonding performance index of the propellant / liner bonding interface. The method has the characteristics of convenient detection process, good data repeatability, reliable parameter analysis and optimal data processing.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Air tightness testing device forelectronic component

InactiveCN112326152ARealize visualizationReduce cosmetic damageMeasurement of fluid loss/gain rateEngineeringElectronic component

The invention discloses an air tightness testing device for an electronic component. The air tightness testing device comprises a sealing shell, an electric cabinet module, a carrier module, a platform frame module and a pressure head module; the electric cabinet module is arranged at the bottom of the sealing shell; a to-be-tested part is placed on the carrier module; the carrier module moves into the sealing shell; the to-be-tested part is moved to the position below a platform frame; and the pressure head module and the carrier module are aligned for air pressure airtight test. According tothe air tightness testing device, positive and negative air pressure air tightness testing can be carried out, and visualization of a testing result is achieved; the test precision is high, and the data repeatability and correlation are good; a sealing assembly is contacted with the to-be-tested part, so that the appearance damage of the to-be-tested part is reduced.

Owner:南通名濠新能源科技有限公司

Fast nondestructive detection cover for formaldehyde emission as well as nondestructive detection method

InactiveCN103969083ASimple structureEasy to carryWithdrawing sample devicesWood testingEngineeringRepeatability

The invention relates to a fast nondestructive detection cover for formaldehyde emission as well as a nondestructive detection method. The fast nondestructive detection cover for formaldehyde emissioncomprises a cover body, a cover port and a sampling detection port, wherein sealing gaskets are mounted on the cover port and the sampling detection port respectively, and air in the cover can be in a relatively sealed state during detection. The nondestructive detection method comprises the following steps: (1), the surface of a to-be-detected sample is directly covered with the cover port of the detection cover; (2), a portable direct-reading formaldehyde analyzer is placed directly in the cover or the sampling detection port of the detection cover; (3), the sealing gaskets on the sampling detection port and the cover port are sealed, the initial concentration A0 of formaldehyde in the air in the cover is read directly from the formaldehyde analyzer; (4) after a certain time, the final concentration A1 of formaldehyde inthe air in the cover is read directly from the formaldehyde analyzer; and (5) the difference between A1 and A0, namely, the difference between the final concentration and the initial concentration is calculated, and the difference is the formaldehyde emission of the to-be-detected sample in the certain time. The fast nondestructive detection cover is simple in structure, high in applicability, low in cost and good in measured data repeatability, and the formaldehyde emission of to-be-detected furniture and decoration materials in the practical using environment can be reflected truly and objectively without damaging the detected sample.

Owner:王盛良

On-line tester of phosphor powder tube

InactiveCN101806739AGuaranteed accuracyImprove in-line quality controlFluorescence/phosphorescencePhosphorLight beam

The invention discloses an on-line tester of a phosphor powder tube. The existing phosphor powder tube excitation device is difficult to ensure the accuracy of the on-line test of the phosphor powder tube. The on-line tester of the phosphor powder tube is characterized in that an ultraviolet lamp tube controlled by a switch, a lamp tube clamp which can adjust the position and corresponds to the ultraviolet lamp tube, and a light color detector are arranged on a seat body, and the light color detector is connected with a data processing instrument; the light beam inlet of the light color detector is provided with a light transmission piece capable of preventing dust from entering the light color detector, and the surface of the whole tester is black so as to prevent the interference caused by reflection. The invention can effectively ensure the accuracy of the online test of the phosphor powder tube, and provides a practical equipment technology guarantee for the online test of the tester.

Owner:杭州创惠仪器有限公司

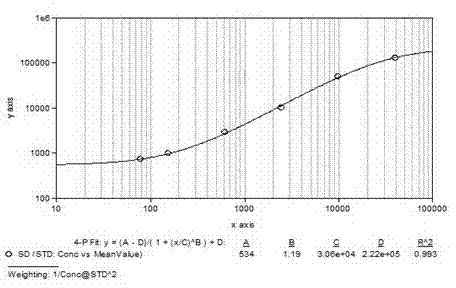

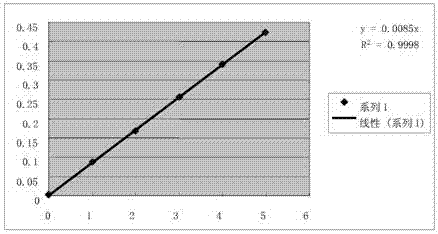

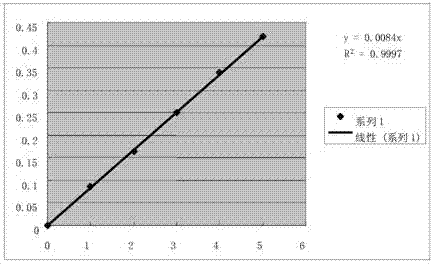

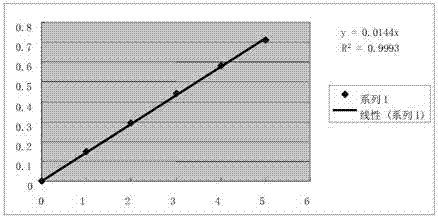

Method for determining niobium content in titanium-niobium alloy

ActiveCN107315001AEliminate distractionsColor stableMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsNiobium alloyLength wave

The invention discloses a method for determining the niobium content in a titanium-niobium alloy. The method comprises: preparing a Ti45Nb sample solution; taking the Ti45Nb sample solution, and developing the color with a PAR solution; measuring the absorbance of the developed solution at a wavelength of 520-530 nm on a spectrophotometer; preparing a niobium standard solution; preparing a titanium base solution; preparing a series of standard solutions for establishing the niobium concentrations from 0.00%-0.25*10<-3>% of a curve, wherein the solutions are corresponding to the niobium concentrations from 0-50% in the sample; establishing a working curve, wherein a series of standard solutions of S6 are subjected to color development, the absorbance values are measured, and the working curve using the concentrations as a abscissa and the absorbance values as an ordinate is established; and dissolving the Ti45Nb sample, developing the color, determining the absorbance value, and obtaining the corresponding concentration value in the established working curve by using the determined absorbance value so as to obtain the niobium content in the Ti45Nb memory alloy material. According to the present invention, the method has advantages of stable color development, satisfactory working curve, and good data repeatability.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

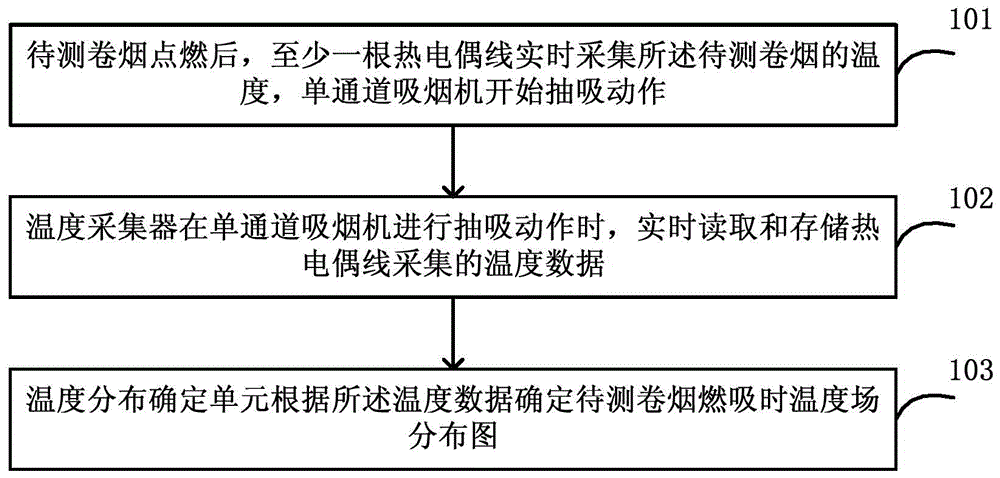

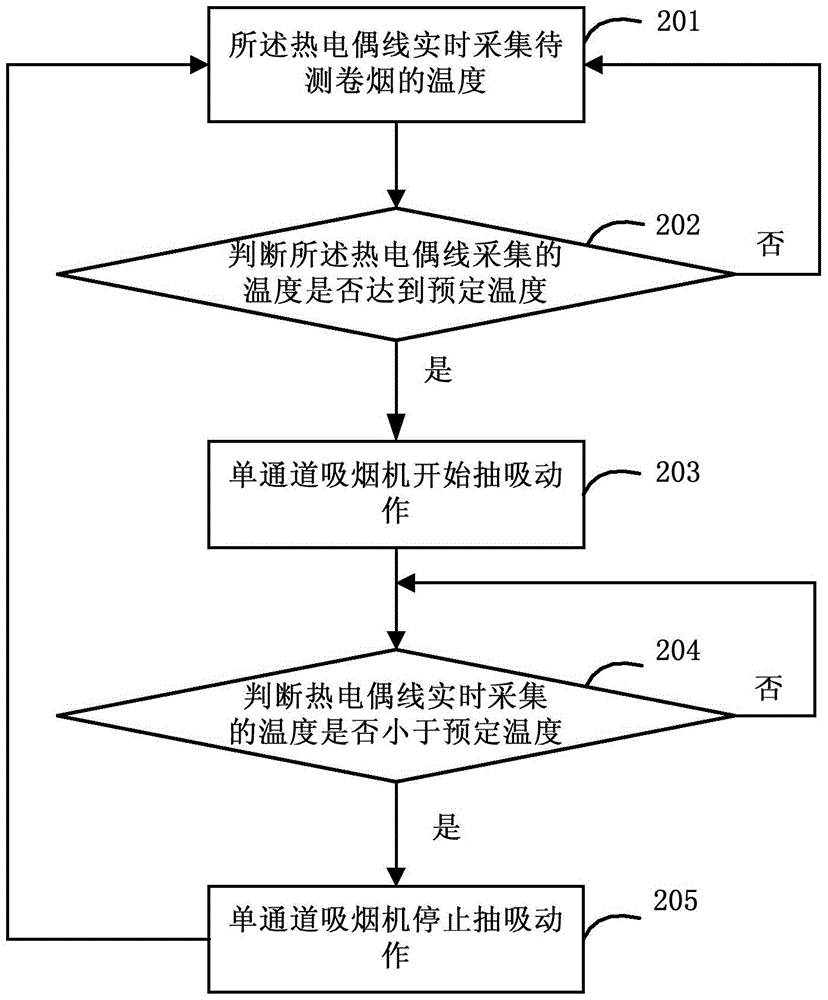

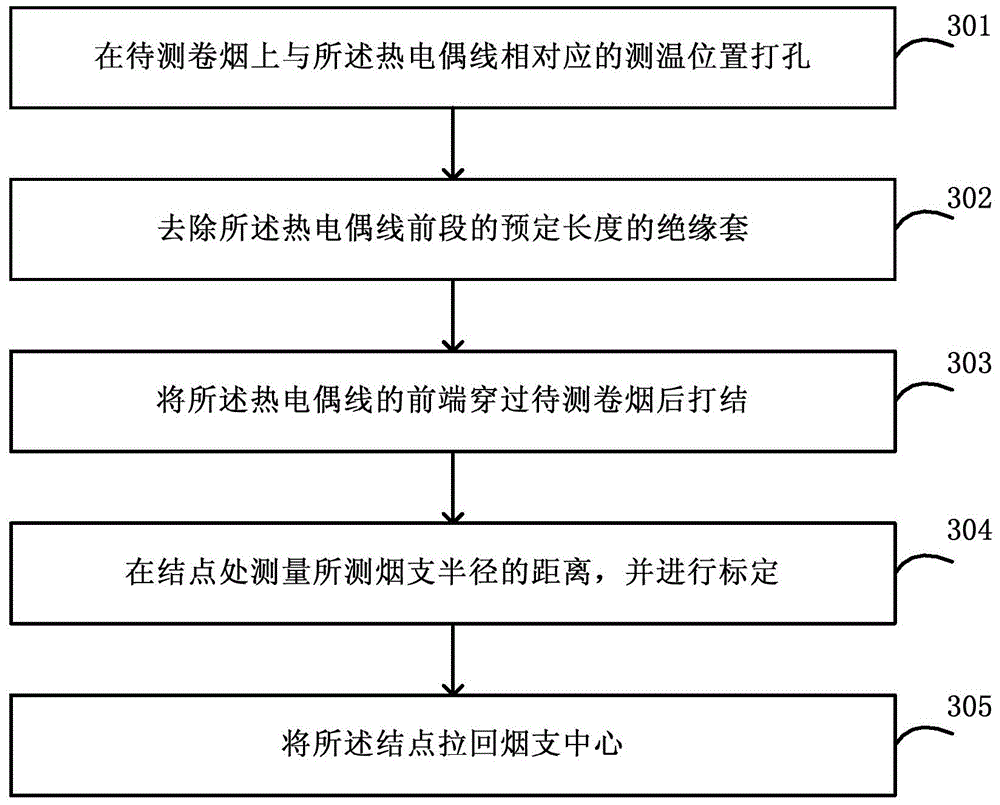

Method, related device and system for detecting temperature field distribution during cigarette smoking

ActiveCN103983370BThe testing process is simpleGood data repeatabilityChemical analysis using combustionThermometers using electric/magnetic elementsProcess engineeringThermocouple Wire

Owner:CHINA TOBACCO FUJIAN IND +1

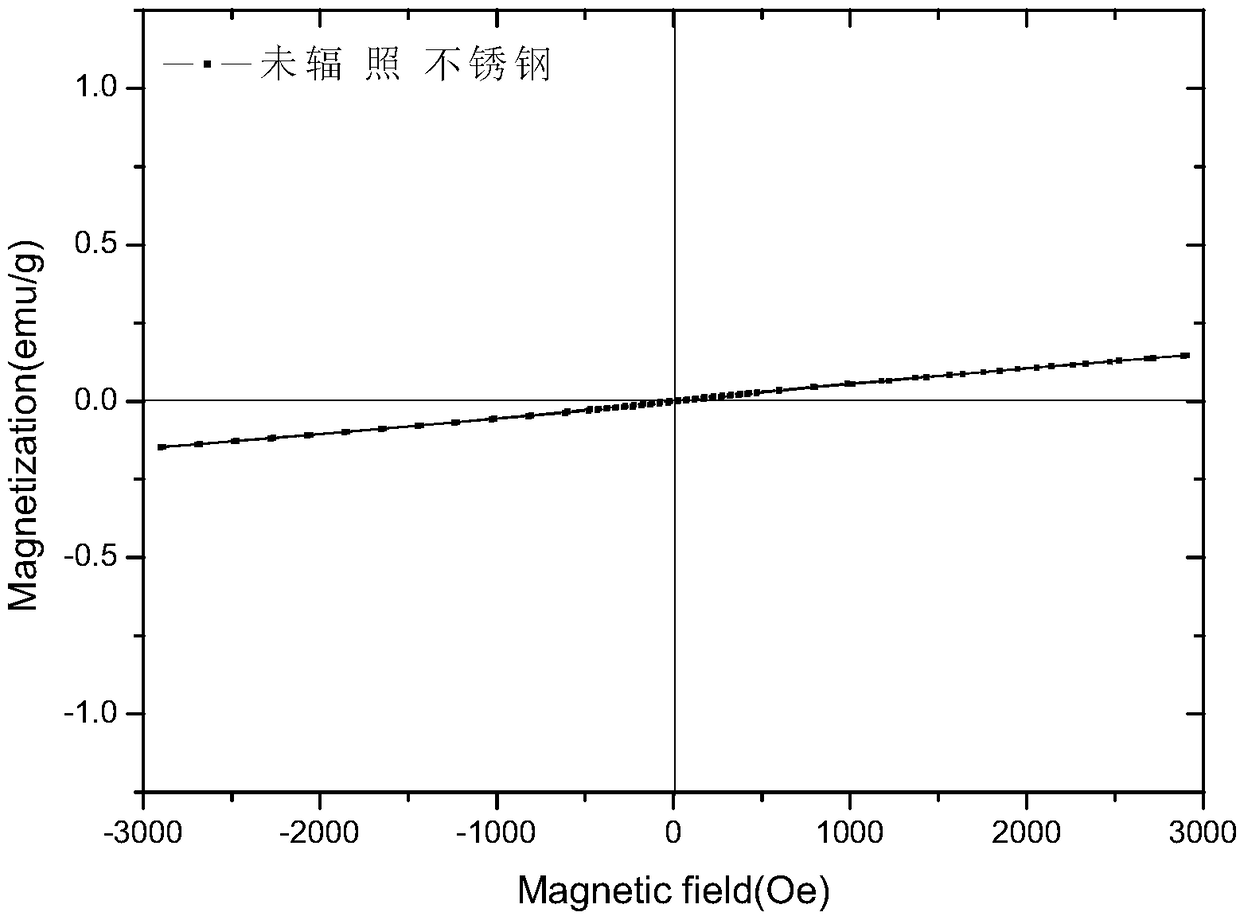

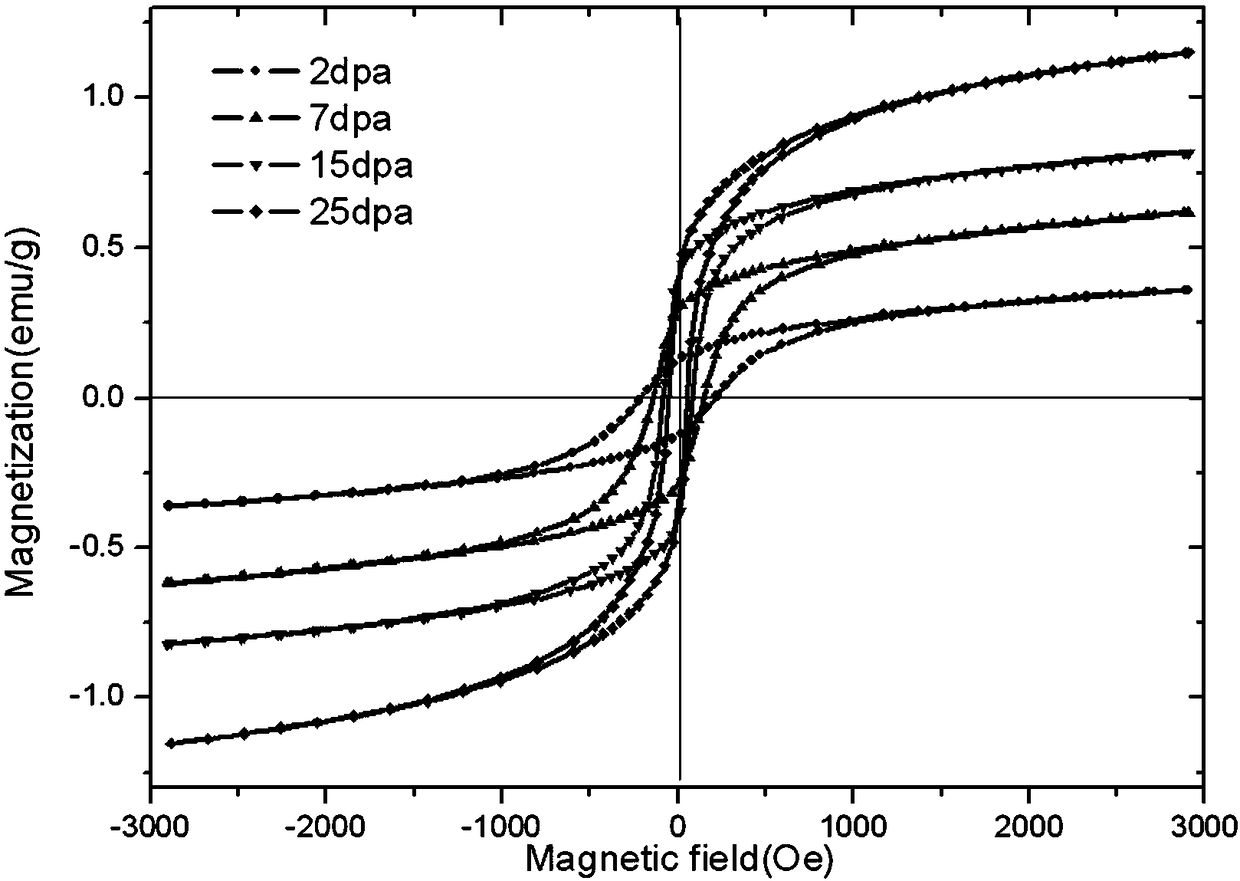

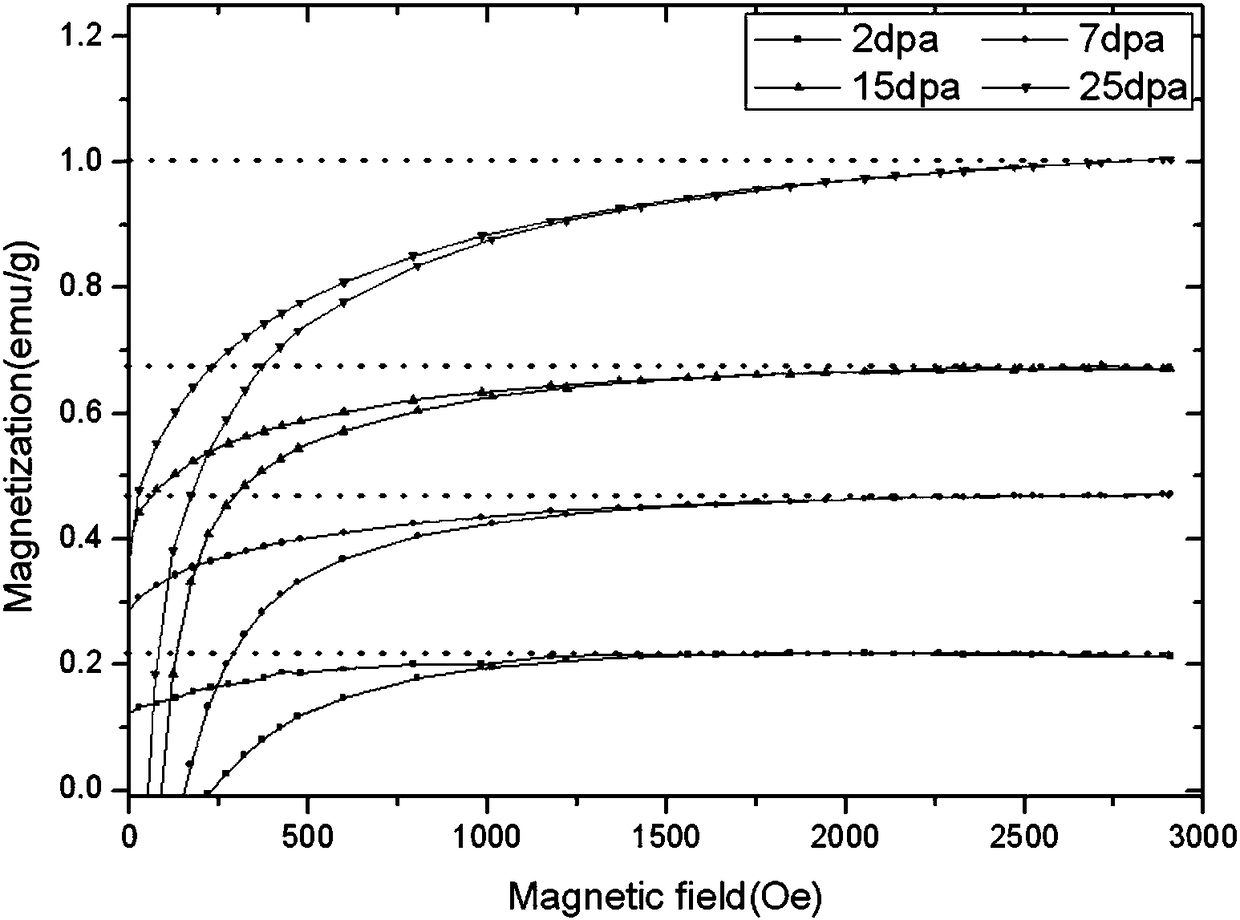

Magnetic nondestructive testing method for testing ferritic transformation quantity of austenitic stainless steel after being subjected to ion irradiation

ActiveCN108333032ASmall sizeThe test data is validPreparing sample for investigationMaterial magnetic variablesHysteresisSolution treatment

The invention discloses a magnetic nondestructive testing method for testing the ferritic transformation quantity of austenitic stainless steel after being subjected to ion irradiation. The method comprises the following steps that (1) austenitic stainless steel is subjected to solution treatment after being processed to be round sheets; (2) the round sheets are subjected to magnetic testing, anda hysteresis loop first M-H curve of non-irradiated austenitic stainless steel is obtained; (3) the round sheets are subjected to ion irradiation, and the equivalent thickness L1 in an ion irradiationdestructive area is obtained; (4) the irradiated austenitic stainless steel is subjected to magnetic testing, and a hysteresis loop second M-H curve of the irradiated austenitic stainless steel is obtained; (5) the contribution of the non-irradiated austenitic stainless steel on the first M-H curve is deducted from the second M-H curve, and the specific saturation magnetization Ms of the irradiated austenitic stainless steel is obtained; (6) the specific saturation magnetization Mst of the irradiation destructive part is calculated by adopting the formula I (detailed description is shown in the original text); and (7) the ferritic transformation quantity of austenitic stainless steel after obtaining ion irradiation is calculated by adopting the formula II (detailed description is shown inthe original text). The method is convenient to test, the sample size is small, the data accuracy is high, and the repeatability is good.

Owner:SUZHOU NUCLEAR POWER RES INST +3

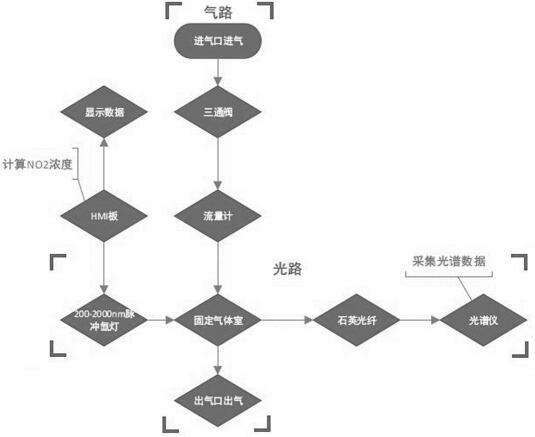

Method for detecting ultraviolet differential nitrogen dioxide gas

PendingCN112824875AImprove data accuracyGood data repeatabilityColor/spectral properties measurementsNitrogen dioxidePhysical chemistry

The invention discloses a method for detecting ultraviolet differential nitrogen dioxide gas. The method comprises the following steps: collecting sample gas; making a standard curve: introducing 99.999% nitrogen into the gas chamber at a flow rate of 2L / min, collecting an N2 spectrum and storing data, then introducing NO2 standard gas, and collecting NO2 spectrum data; and by utilizing a Lambert-Beer law, calculating the molar absorption coefficient of NO2 based on a 100% NO2 standard absorption curve, then, substitutingthe molar absorption coefficient of NO2 into data of the first several groups of spectrums, and calculating the actual concentration, wherein it is obtained according to multiple experiments that deviation exists between the actual concentration and the theoretical concentration, the actually calculated concentration needs to be corrected, and after correction through a third-order function, the actual concentration and the theoretical concentration are within a required error range. According to the method, the concentration of NO2 in the gas is measured by utilizing an ultraviolet spectrum differential technology, and the method has good data accuracy and repeatability and wide application range.

Owner:杭州绰美科技有限公司

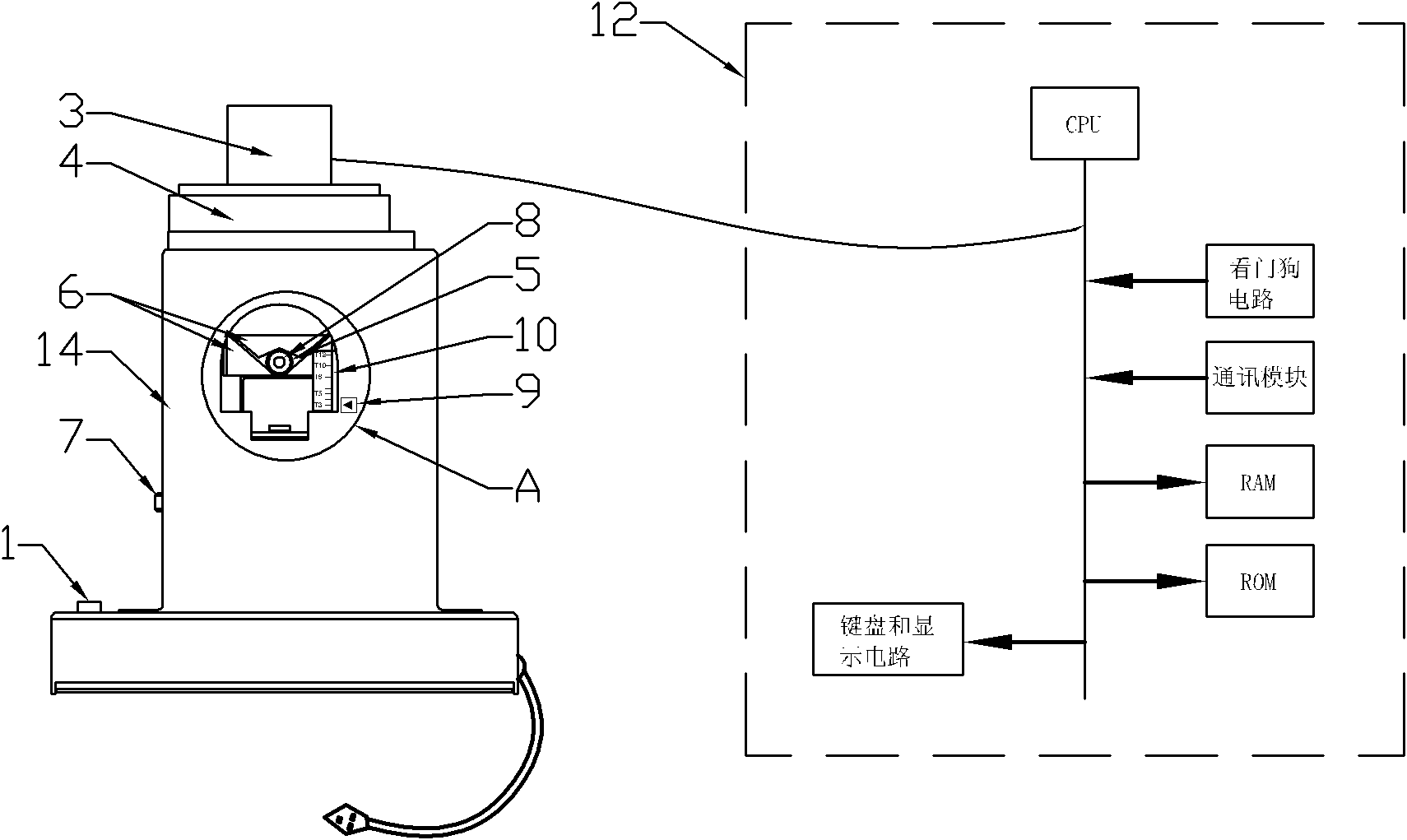

Liquid recognition and detection automatic sample injector with adjustable temperature

InactiveCN102419376AImprove test accuracyGood data repeatabilityMaterial analysisInjectorEngineering

The invention discloses a liquid recognition and detection automatic sample injector with adjustable temperature. The sample injector is composed of a frame, a sample injection assembly, a detection assembly, a temperature-adjusting assembly and a control system; the sample injection assembly is provided with a supporting plate, a supporting frame, a water bath pool, a locating plate, a driving synchronizing wheel, a sample injection stepping motor, a synchronizing belt, a driven synchronizing wheel and the like; the water bath pool is fixed on the driven synchronizing wheel, the bottom of the water bath pool is provided with a locating gage mark, the supporting plate, the supporting frame and the locating plate are fixed in the water bath pool after being connected rigidly; the temperature-adjusting assembly is provided with a heater, a refrigerator, a refrigerating heat exchanger, a stirrer, a stirring motor, a temperature control bracket and the like; a spiral heater and the refrigerating heat exchanger are concentrically fixed below the temperature control bracket, the stirring motor is mounted above the temperature control bracket, the stirrer is fixed on the stirring motor, and a through axis of the stirrer is coincident with the central line of the heater. The automatic sample injector provided by the invention can be used for carrying out constant-temperature detectionon samples under a set constant temperature condition at different environment temperatures; the temperature is adjustable, the samples are automatically injected and the testing precision is high.

Owner:ZHEJIANG UNIV

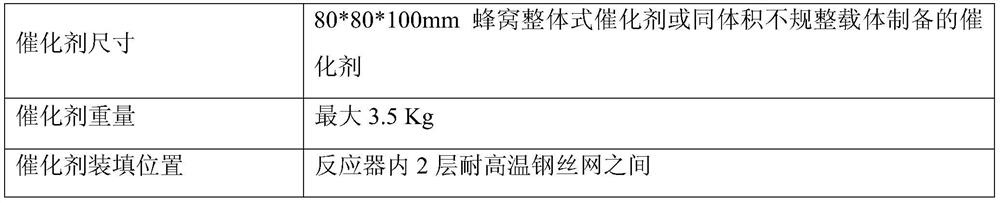

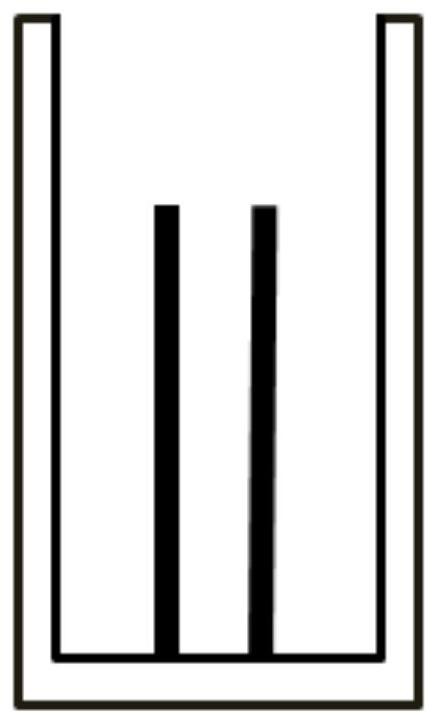

Catalytic Combustion Evaluation Device and Test Method for Volatile Organic Compounds

ActiveCN107478732BLarge loading capacityIncrease authenticityComponent separationIncinerator apparatusPtru catalystLaboratory device

The invention belongs to the technical field of catalyst evaluation and particularly relates to a volatile organic compound catalytic combustion evaluation device and a test method. The volatile organic compound catalytic combustion evaluation device comprises a reactor, the reactor is respectively connected to a gas mass flow meter and a metering pump, the reactor, a heat exchanger, a condenser, a gas-liquid separator, a wet flow meter, a drying pipe and a gas chromatograph are orderly connected to a computer, the heat exchanger is connected to a blower, the gas-liquid separator is connected to a liquid storage tank and an exhaust head is respectively connected to the wet flow meter and the drying pipe. The device has a large filling amount, can be filled with a whole honeycomb-type monolith catalyst, can acquire test data having high authenticity, is conducive to conversion from a laboratory device into an industrial device, is provided with the heat exchanger, fully utilizes heat and reduces laboratory power consumption.

Owner:CHINA PETROLEUM & CHEM CORP

Construction method and application of sequencing library of circular small non-coding RNA (Ribonucleic Acid)

PendingCN113684247AImprove accuracyIncrease credibilityMicrobiological testing/measurementLibrary creationCulture cellTotal rna

The invention relates to a construction method and application of a sequencing library of circular small non-coding RNA (Ribonucleic Acid). The construction method comprises the following steps: (1) culturing cells; (2) extracting total RNA (Ribonucleic Acid) from the cells; (3) extracting RNA by using a small RNA extraction kit, and removing 28S and 18S rRNA; (4) further removing 5S and 5.8 S rRNA by an RAP method; (5) removing linear RNA; and (6) constructing the sequencing library of the circular small non-coding RNA. The constructed sequencing library of the circular small non-coding RNA has the advantages of few rRNA residues, high detection efficiency of the circular RNA, high sequencing flux, better data repeatability and high success rate of verification of a sequencing result. The whole method is simple and convenient to operate, low in cost and time consumption, high in stability and very good in repeatability and reliability.

Owner:深圳市龙华区中心医院

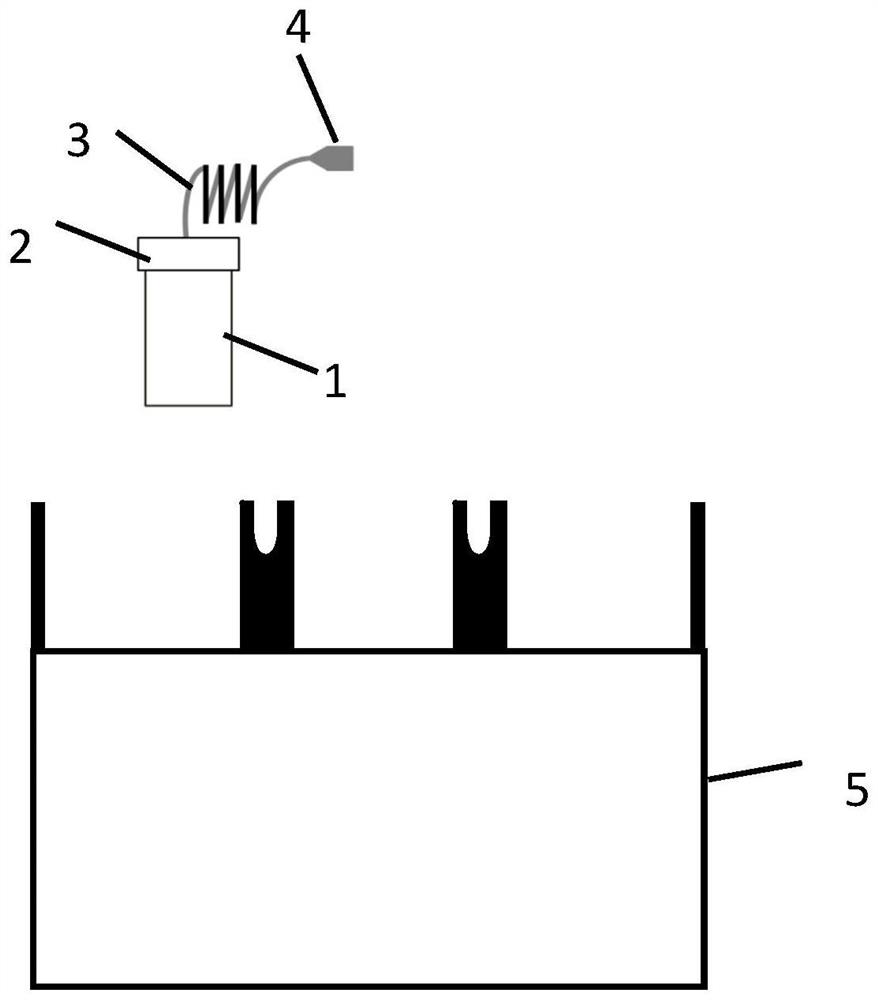

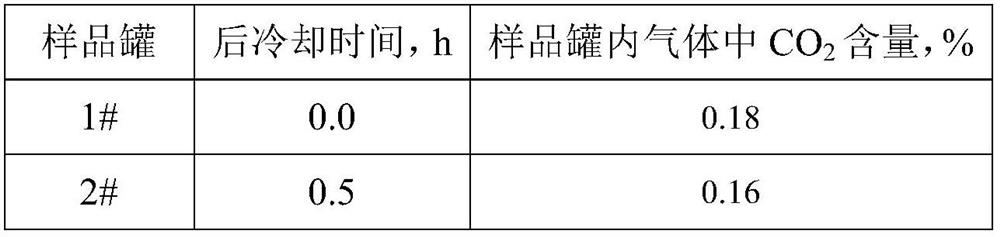

Sample heating and post-cooling device for detecting propellant decomposition gas

ActiveCN113075334AShort warm-up timeShorten warm-up timeComponent separationPhysical chemistryEngineering

The invention discloses a sample heating and post-cooling device for detecting propellant decomposition gas. The sample heating and post-cooling device comprises a tank body, a cap, a cooling pipe, a gas production port and a heating furnace, the tank body is a barrel body, a heat conduction column is arranged in the tank body, the cap is provided with an air hole, and the cap and the tank body are assembled into the sample tank by tightening threads. The left end of the spring-shaped cooling pipe is connected with the air hole of the sample tank cap, and the right end of the cooling pipe is communicated with the sampling port. The sample tank filled with the propellant powder into a heating hole of a heating furnace, heating is performed at 90 DEG C for 3 hours, and gas in the sample tank is extracted for detection. Compared with an original device, the device disclosed by the invention has the advantages of uniform sample heating, high sample temperature rising speed, capability of rapidly cooling decomposition gas to be detected and the like, the precision of a detection result is improved, and the sample heating and post-cooling time is shortened.

Owner:XIAN MODERN CHEM RES INST

On-line tester of phosphor powder tube

InactiveCN101806739BGuaranteed accuracyImprove in-line quality controlFluorescence/phosphorescencePhosphorOnline test

The invention discloses an on-line tester of a phosphor powder tube. The existing phosphor powder tube excitation device is difficult to ensure the accuracy of the on-line test of the phosphor powder tube. The on-line tester of the phosphor powder tube is characterized in that an ultraviolet lamp tube controlled by a switch, a lamp tube clamp which can adjust the position and corresponds to the ultraviolet lamp tube, and a light color detector are arranged on a seat body, and the light color detector is connected with a data processing instrument; the light beam inlet of the light color detector is provided with a light transmission piece capable of preventing dust from entering the light color detector, and the surface of the whole tester is black so as to prevent the interference causedby reflection. The invention can effectively ensure the accuracy of the online test of the phosphor powder tube, and provides a practical equipment technology guarantee for the online test of the tester.

Owner:杭州创惠仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com