Adjustable n-shaped mixer

A mixer and adjustable technology, applied in the field of mixing equipment, can solve the problems of inaccurate polymer concentration, approaching a static state, and loss of uniform mixing, so as to reduce mechanical shearing, reduce viscosity loss rate, and ensure authenticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

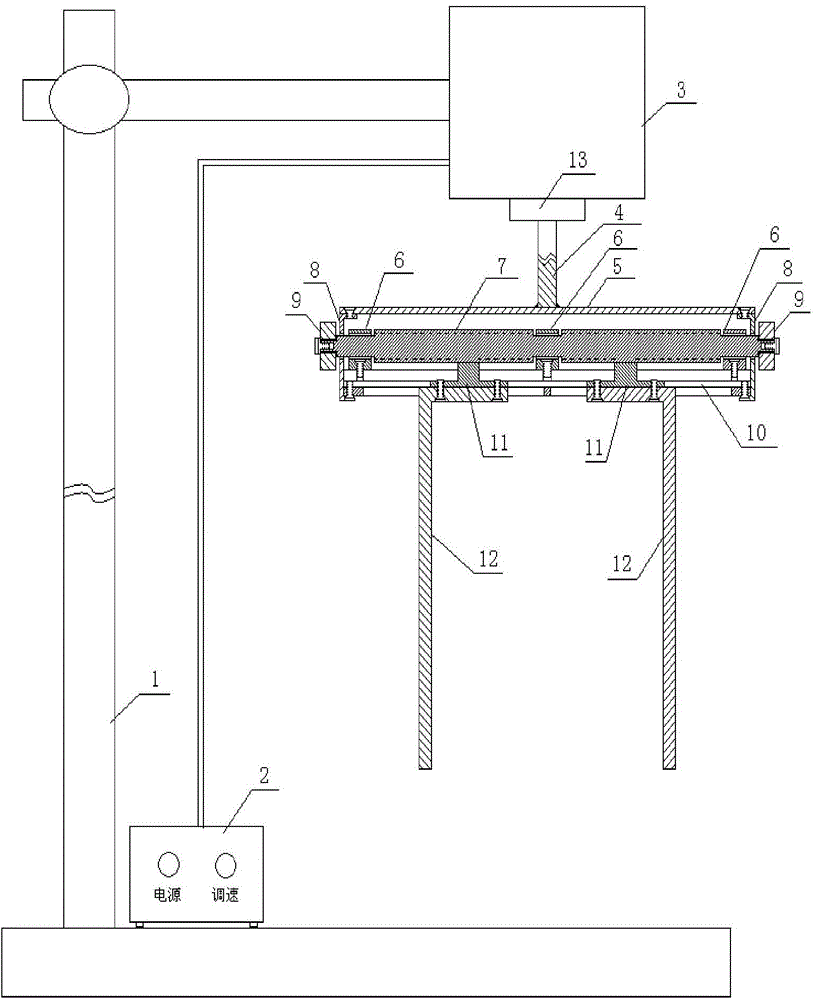

[0025] Such as figure 1 As shown, according to the specification and shape of the existing polymer container, combined with the characteristics of the polymer water-soluble process, the adjustable n-type mixer of the present invention has been developed. The adjustable n-type mixer of the present invention consists of a support frame 1, a power governor 2, a motor 3, a motor connecting shaft 4, a stirring plate regulator 5, a screw clip 6, a screw 7, a box plug 8, a hand wheel 9, a sliding Road 10, tooth slider 11, stirring plate 12 and motor chuck 13 are formed. The adjustable n-type mixer of the present invention is shaped like an "n" type, and is generally divided into two parts: one is an electric drive and support part; the other is a stirring part.

[0026] 1. Electric drive and bracket part

[0027] It includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com