Fast nondestructive detection cover for formaldehyde emission as well as nondestructive detection method

A technology of formaldehyde emission and detection cover, which is applied in the field of furniture and decoration materials, can solve the problems of environmental pollution, time-consuming device detection, and high detection and operation cost, and achieves the effects of good data repeatability, simple and convenient operation, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

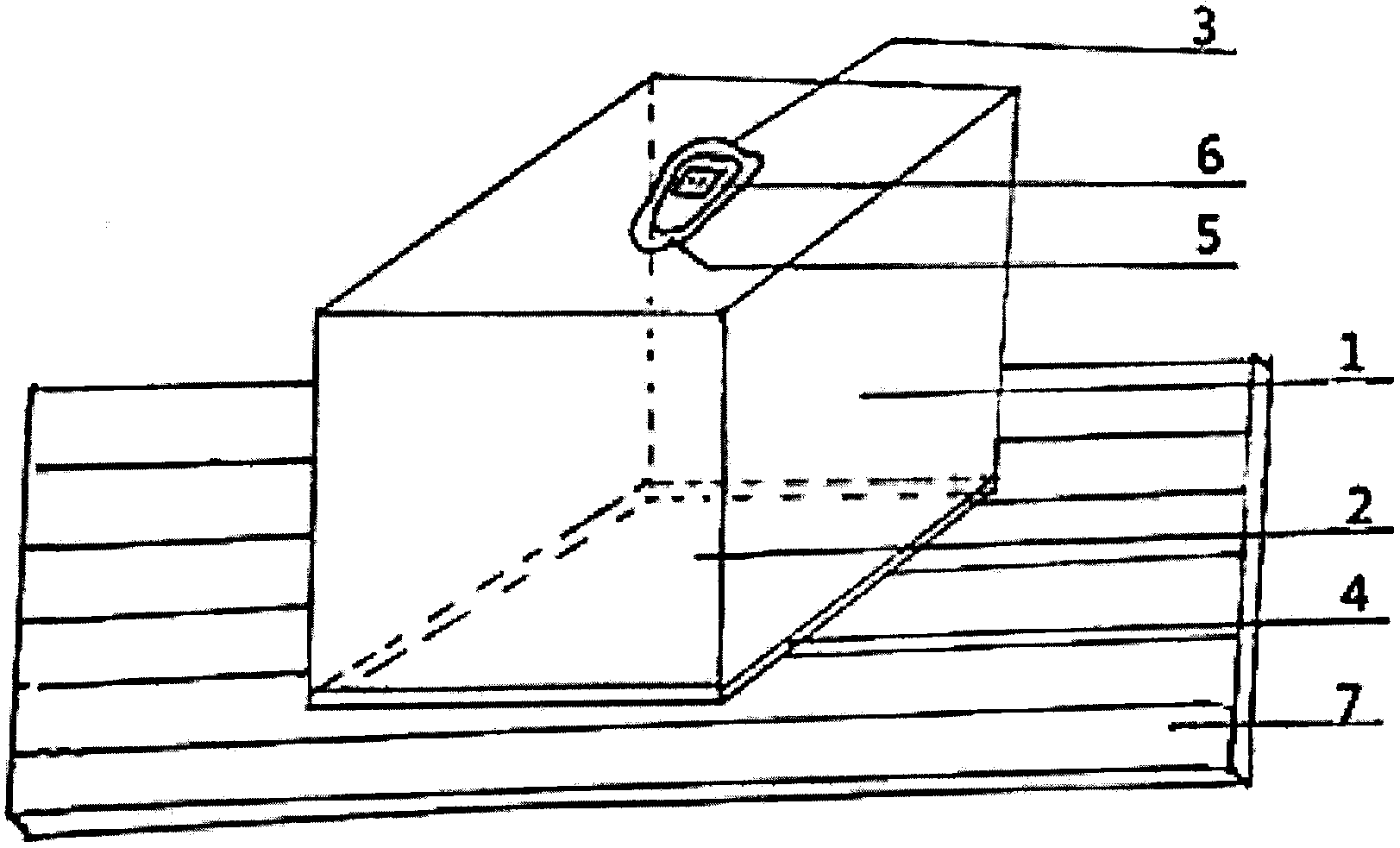

[0021] Attached figure 1 It is a rapid non-destructive detection cover for formaldehyde emission of the present invention, which is composed of a cover opening (2), a cover body (1) and a sampling detection port (3). The cover opening is provided with a gasket (4) and the sampling detection port is provided with a gasket ( 5). Under the cover seal is the laminate floor (7) to be tested.

[0022] The method of using the above-mentioned formaldehyde emission rapid non-destructive detection cover includes the following steps:

[0023] (1) Cover the mouth of the detection cover directly on the surface of the laminate floor of the sample to be tested;

[0024] (2) Place the portable direct-reading formaldehyde analyzer (6) directly on the sampling detection port (3);

[0025] (3) Seal the gasket (5) of the sampling inspection port and the gasket (4) of the cover, and read the initial concentration A of the air in the cover directly from the formaldehyde analyzer 0 ;

[0026] (4) After a ce...

Embodiment 2

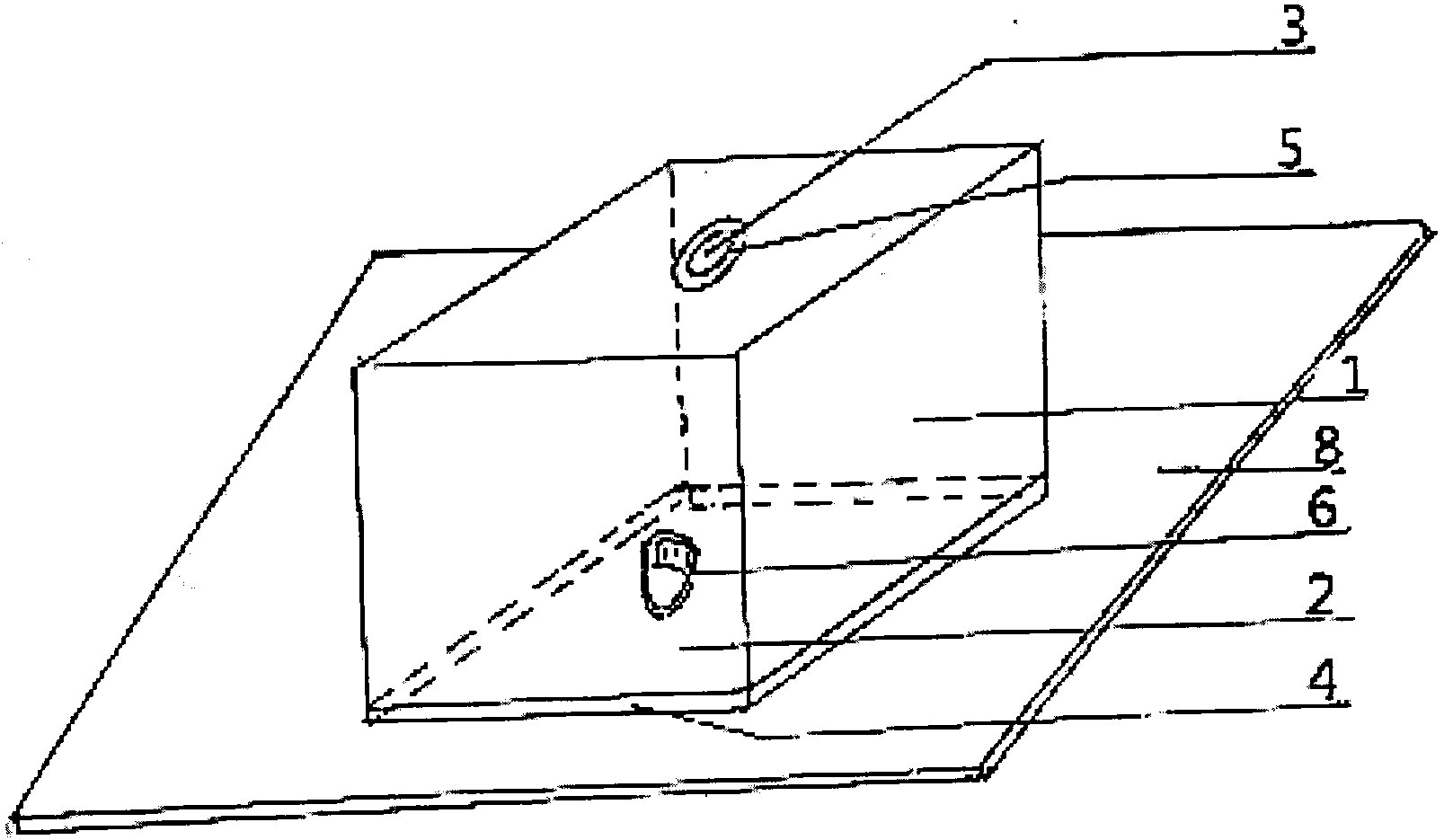

[0029] Attached figure 2 The cover for the rapid and non-destructive detection of formaldehyde emission of the present invention is composed of a cover opening (2), a cover body (1) and a sampling inspection port (3). The cover opening is provided with a gasket (4) and the sampling detection port is provided with a gasket (5). Under the cover seal is the cabinet partition (8) of the furniture to be inspected.

[0030] The method of using the above-mentioned formaldehyde emission rapid non-destructive detection cover includes the following steps:

[0031] (1) Cover the detection cover directly on the surface of the sample furniture cabinet partition to be tested;

[0032] (2) Put the portable direct-reading formaldehyde analyzer (6) directly in the cover;

[0033] (3) Seal the gasket of the sampling inspection port and the gasket of the cover mouth, and read the initial concentration A of formaldehyde in the air in the cover directly from the formaldehyde analyzer 0 ;

[0034] (4) Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com