Non-destructive detection method of storage ageing performance of propellant/liner bonding interface

A non-destructive detection, storage aging technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem of reflecting the NEPE propellant/liner bonding interface, etc., to achieve convenient detection process and parameter analysis Reliable, data-processing optimized results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] step one,

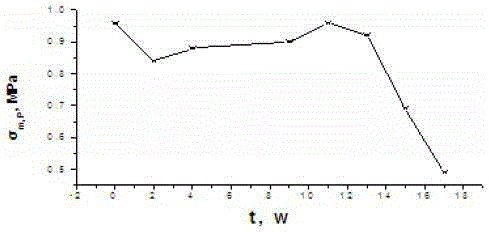

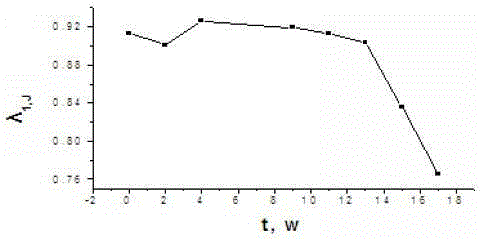

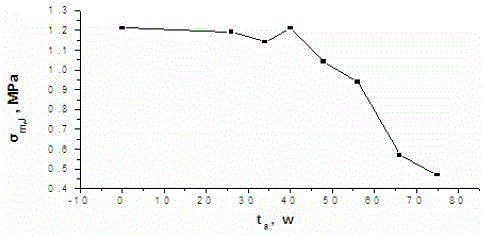

[0018] (1) Put the standard rectangular specimen of NEPE propellant into an explosion-proof aging oven with a specified temperature of 70°C for accelerated aging, take samples regularly to measure the mechanical properties, and obtain the change data and rules of the tear-off strength of the standard rectangular specimen with aging temperature and aging time .

[0019] (2) Preparation of infrared spectrum test samples. First, use a special standard rectangular sample preparation tool to separate the required sample (that is, the sample composed of propellant / liner / insulation layer) between the steel plate and the insulation layer; secondly, use a biological microtome to cut off the excess NEPE Propellant, so that the sample only retains about 50 μm of NEPE propellant material (the so-called interface material) at the bonding interface formed between the NEPE propellant and the liner.

[0020] (3) The sample with about 50 μm of the interface material retain...

Embodiment 2

[0033] step one,

[0034] (1) Put the standard rectangular specimen into an explosion-proof aging oven with a specified temperature of 60°C for accelerated aging, and regularly sample and test its mechanical properties to obtain the data and rules of the standard rectangular specimen with aging temperature and aging time.

[0035] (2) Preparation of infrared spectrum test samples. First, use a special standard rectangular specimen sample preparation tool to separate the required sample (that is, the sample composed of propellant / lining layer / thermal insulation layer) between the steel plate and the thermal insulation layer of the standard rectangular specimen; secondly, use biological slices The excess NEPE propellant is cut off by machine, so that only about 50 μm of NEPE propellant material (the so-called interface material) remains at the bonding interface formed between the NEPE propellant and the liner.

[0036] (3) The sample with about 50 μm of the interface material r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com