Sample heating and post-cooling device for detecting propellant decomposition gas

A technology of cooling device and propellant, which is applied in the direction of measuring device, material separation, and analysis of materials, etc. It can solve the problems of accelerated decomposition reaction, long warm-up time, uneven temperature distribution of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

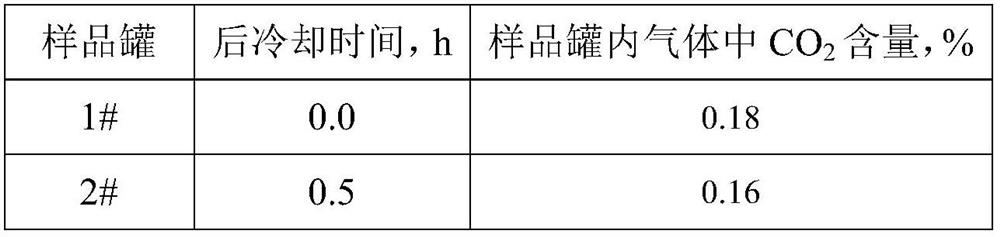

[0068] Use the device of the present invention to heat a certain batch of small propellants produced in 2017, and detect the CO in the pyrolysis gas 2 and NO 2 content.

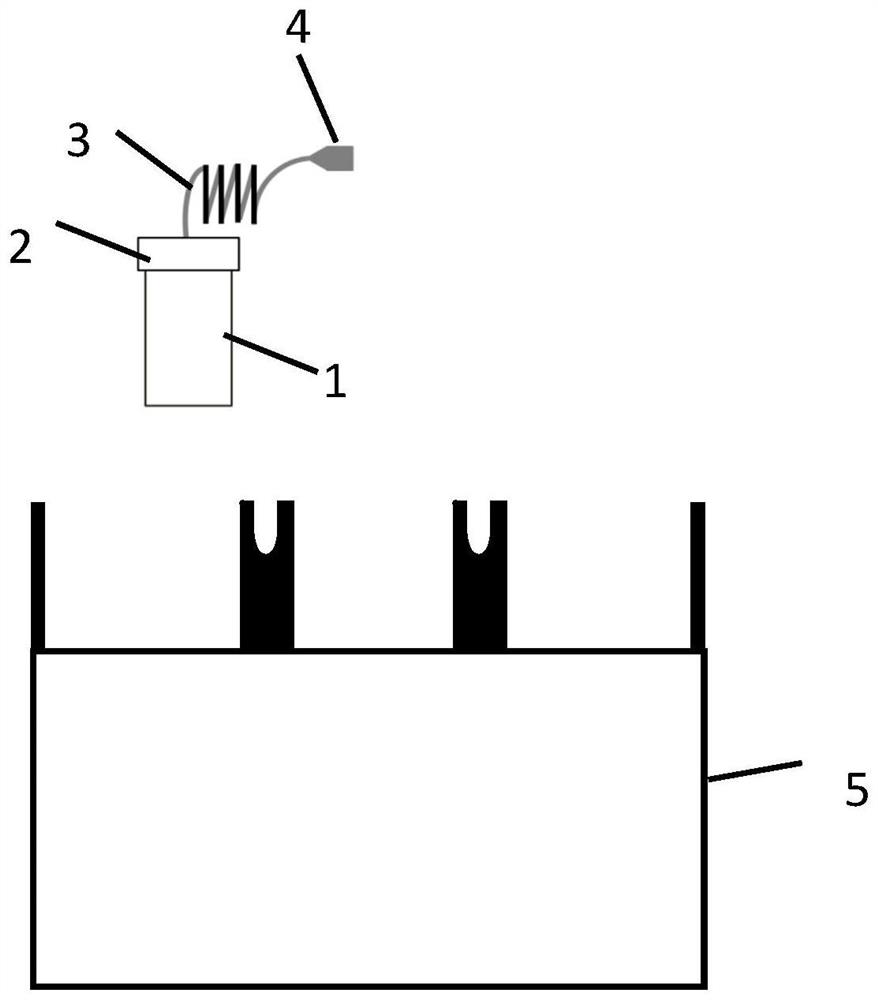

[0069] A sample heating and post-cooling device for detecting propellant decomposition gas, characterized in that the device includes a tank body 1, a cap 2, a cooling pipe 3, a gas sampling port 4 and a heating furnace 5;

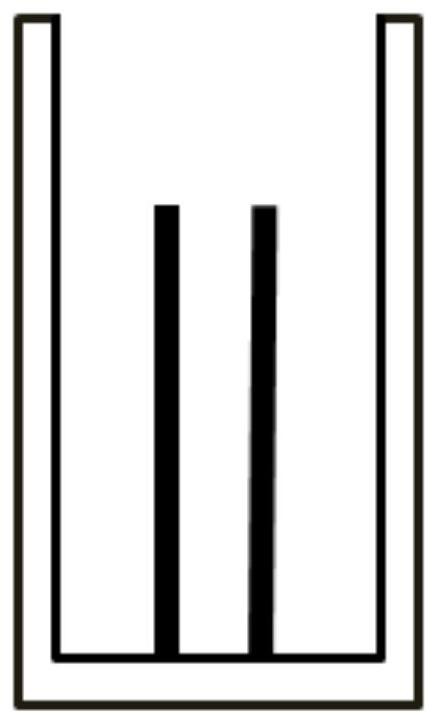

[0070] Such as figure 1 As shown, the tank body 1 is a revolving body, and the tank body 1 is composed of two parts, the inside and the outside. On the plane; the diameter of the heat conduction column is 2mm, the height is 60mm, and the heat conduction column is evenly distributed on the circle with a radius of 4mm from the center of the inner bottom plane of the cylinder; the wall thickness of the tank body 1 cylinder is 2mm, the outer diameter is 30mm, and the outer height is 82mm , the upper end of the outer surface of the barrel is the first external thread area, and the height o...

Embodiment 2

[0087] Prepare a batch of simulated stock propellants by aging in the laboratory: thermally age a batch of tubular propellants at 95°C, and confirm through the bromination method that the stabilizer content has been reduced by 80%, which is equivalent to the propellants that have been in stock for many years , the stabilizer is too small to be able to absorb NO in the decomposition gas 2 , using the present invention to detect CO in the pyrolysis gas of the simulated stockpile propellant sample 2 and NO 2 content.

[0088] Such as figure 2 As shown, a sample heating and post-cooling device for detecting propellant decomposition gas is characterized in that the device includes a tank body 1, a cap 2, a cooling pipe 3, a gas sampling port 4 and a heating furnace 5;

[0089] The tank body 1 is a revolving body, the tank body 1 is composed of two parts inside and outside, the outside of the tank body 1 is divided into a drum body, and the inside of the tank body 1 is divided i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com