Catalytic Combustion Evaluation Device and Test Method for Volatile Organic Compounds

An organic compound, catalytic combustion technology, applied in the combustion method, combustion type, measurement device and other directions, can solve the problems of less catalyst loading, too ideal reaction state, unable to load honeycomb monolithic catalyst, etc., to achieve accurate test data, The effect of good data repeatability and large loading volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

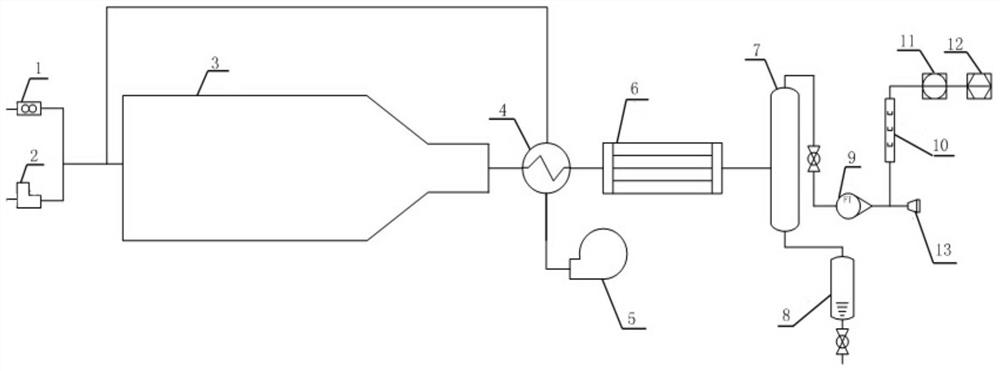

[0045] Such as figure 1 As shown, the volatile organic compound catalytic combustion evaluation device of the present invention includes a reactor 3, the reactor 3 is connected to the gas mass flow meter 1 and the metering pump 2 respectively, the reactor 3, the heat exchanger 4, the condenser 6, the gas Liquid separator 7, wet flow meter 9, drying pipe 10, gas chromatograph 11 are connected to computer 12 in sequence, heat exchanger 4 is connected to blower 5, gas-liquid separator 7 is connected to liquid storage tank 8, and exhaust head 13 is respectively It is connected with the wet flow meter 9 and the drying pipe 10.

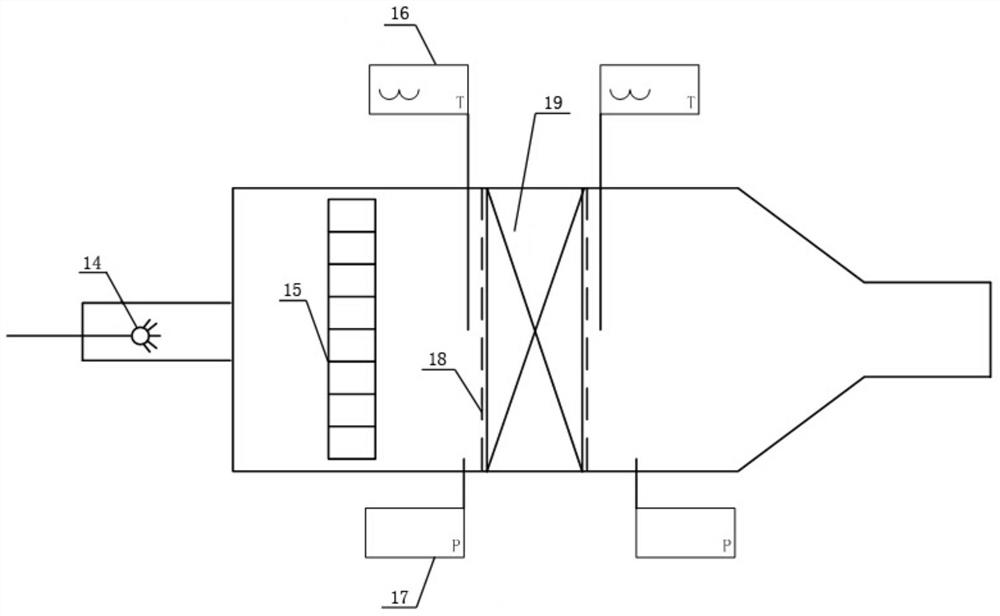

[0046] Such as figure 2As shown, the inside of the reactor 3 is provided with a sprayer 14 , a heating plate 15 and a steel wire mesh 18 sequentially from left to right, and the outside of the reactor 3 is connected with a temperature measuring instrument 16 and a pressure measuring instrument 17 respectively.

[0047] The number of temperature measuring...

Embodiment 2

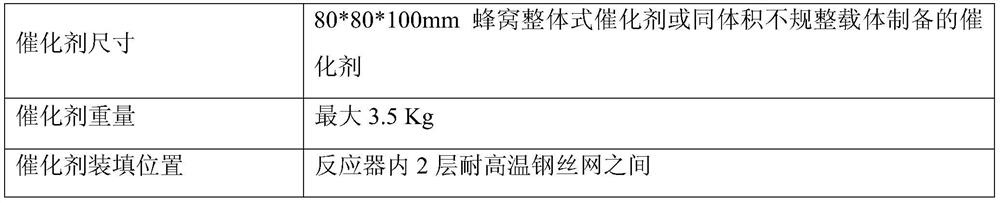

[0054] On the VOCs catalytic combustion evaluation device of the present invention, 3 kg of honeycomb monolithic catalysts are loaded, and the evaluation test is carried out to toluene according to the test method of Example 1, and the evaluation data are shown in Table 4.

[0055] Table 4 Toluene purification results

[0056]

Embodiment 3

[0058] On the VOCs catalytic combustion evaluation device of the present invention, 3.5 kg of the catalyst prepared by filling the irregular carrier was carried out, and the evaluation test was carried out to toluene according to the test method of Example 1, and the evaluation data are shown in Table 5.

[0059] Table 5 Toluene purification results

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com