Method and equipment for pretreatment cabo

A technology of tobacco stem pretreatment and equipment, which is applied in the field of tobacco production, can solve the problems of high safety and environmental protection requirements of expansion agents, easy residual products of expansion agents, and poor expansion uniformity of products, so as to achieve small crushing and improved expansion uniformity , the effect of low pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

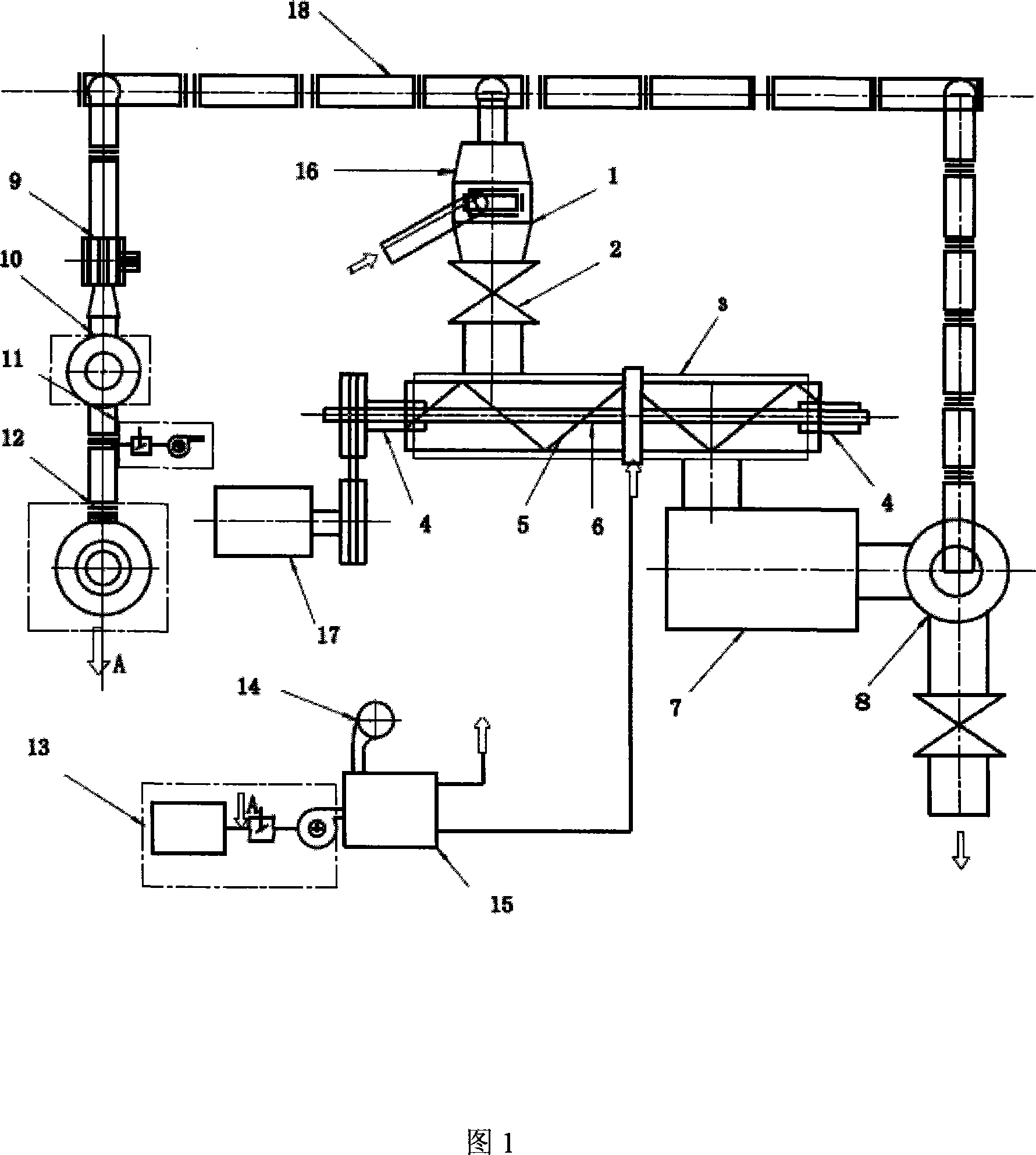

[0029] As shown in Figure 1, the equipment of the present invention comprises a feed section, that is, a substantially vertical feed bin 1, an exhaust hood 16, an induced draft fan 9, a moisture removal system 10, a gas heat medium circulation purification system 11, a gas heat medium Air intake system 12, horizontally arranged preheating horizontal section 5, screw conveying device 6, and microwave composite expander 7, wherein a feed air lock 2 is arranged between the feed bin 1 and the preheating horizontal section 5, and the preheating horizontal The section 5 is provided with a heating jacket 3, and the feed bin 1 is provided with an exhaust hood 16, which are connected to each other through pipes, and the moisture is continuously discharged through the pipes and the induced draft fan 9.

[0030] The screw conveying device 6 is installed at both ends of the preheating horizontal section 5, driven by a motor 17, and the two ends of the shaft are supported by bearings and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com