Sludge harrow type drying method and device

A rake drying and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of low thermal efficiency and low productivity, improve heat utilization rate, improve production capacity, and avoid sticking and agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

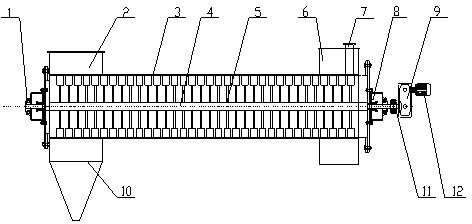

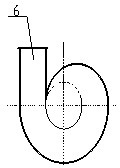

[0021] The structure of the sludge rake drying device is that a left bearing seat 1 and a right bearing seat 8 are respectively provided at both ends of the dryer housing 3, the rotating shaft 4 is located in the dryer housing 3, and the two ends are respectively arranged on the left bearing In the seat 1 and the right bearing seat 8; the part of the rotating shaft 4 located at one end of the right bearing seat 8 is connected to the output end of the reducer 9, and the input end of the reducer 9 is connected to the motor 12 through a coupling 11; at one end of the dryer housing 3 A drying medium inlet 6 and a sludge inlet 7 are arranged on the peripheral wall, a drying medium outlet 2 is arranged on the peripheral wall at one end of the dryer housing 3, a built-in gas-solid separator 10 is provided at the lower part of the drying medium outlet 2, and a Rake teeth 5 are arranged on the wall.

[0022] The drying heat medium enters the sludge rake dryer tangentially from the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com