Solid phase extraction sample bottle and thermal analysis apparatus

A sample bottle and thermal analysis technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve problems such as unsatisfactory, limited enrichment multiples, and inability to handle viscous liquid samples, etc., to improve accuracy and repeatability, improve Preprocessing efficiency, effect of improving data repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

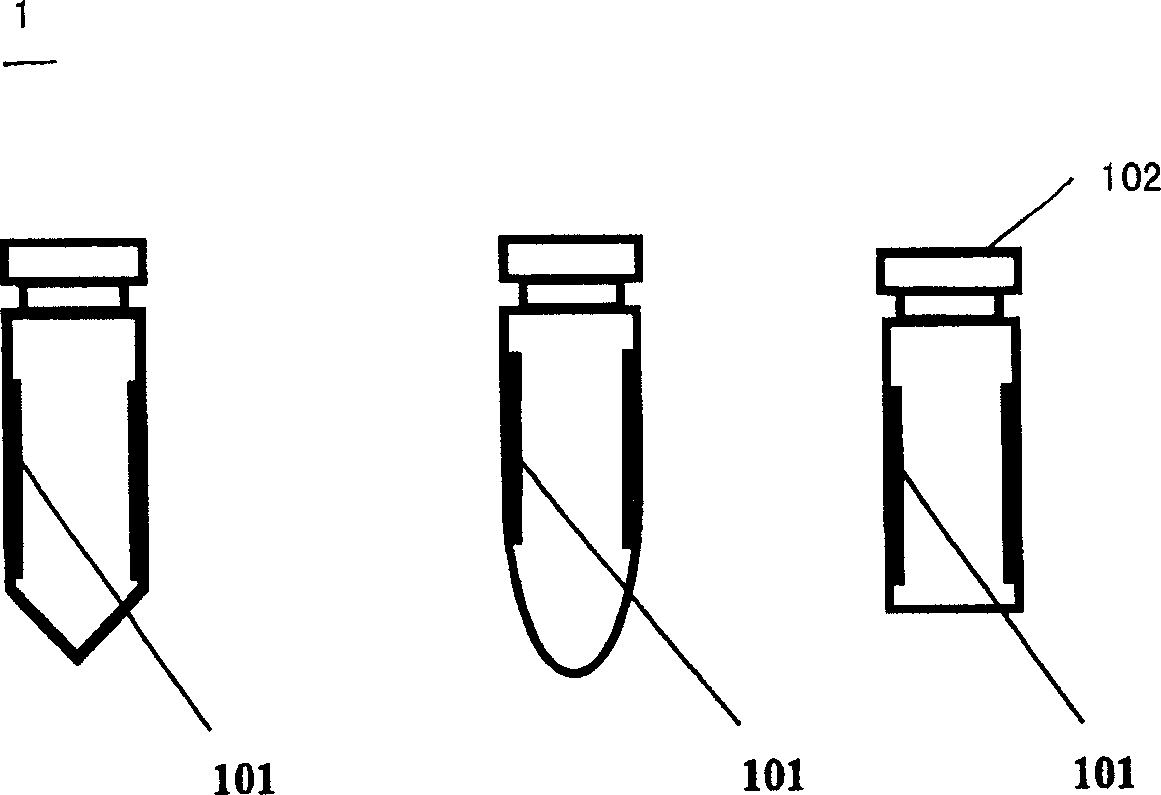

Embodiment 1

[0053] Extraction enriches volatile and semi-volatile organic pollutants in surface water.

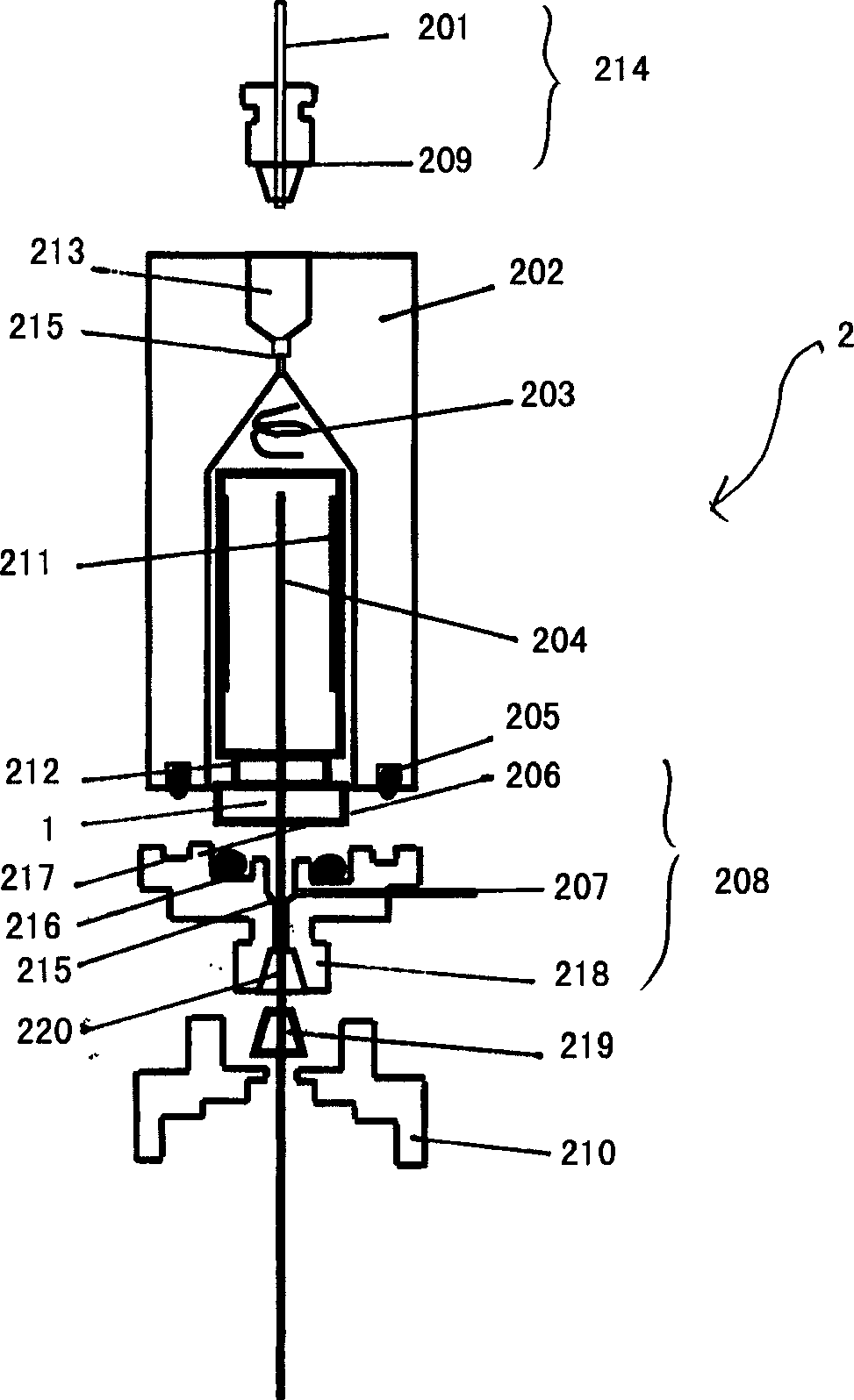

[0054] 1.5mL sample bottle with an inner diameter of 8 mm and a round bottom for adsorption and extraction of samples. The inner wall is coated with 30 mg of cross-linked OV-1 stationary phase, and the film thickness is about 20 μm. Add 1mL of water sample into the bottle, seal it with a rubber pad lined with PTFE film and an aluminum cap, place it on a thermostatic rocker with a swing frequency of 20Hz, and a temperature of 40°C. After extracting for 10min, open the bottle cap and pour out the sample Finally, shake off the residual water droplets in the extraction sample bottle, put the extraction sample bottle into a thermal desorber, set the analysis temperature at 260°C for 6 minutes, and then turn off the heating power. Use an elastic quartz capillary with an inner diameter of 120 μm as the purge gas outlet pipe, and insert it directly into the retention spacer column through the ...

Embodiment 2

[0056] Extract and enrich the pesticide residues in the soil.

[0057] The extraction sample bottle is the same as in Example 1. Take 0.25 grams of soil samples in the extraction sample bottle, add 0.8 mL of twice distilled water, seal it according to the method in Example 1, let the water soak the soil for 5 minutes, and then put it on a constant temperature shaker at 45 ° C. After shaking for 60 minutes, open the bottle cap, then pour out the sample, quickly wash the extraction sample bottle with double distilled water, shake off the residual water droplets in the extraction sample bottle, put the extraction sample bottle into a thermal desorber, and analyze at 280°C for 6 minutes , and then turn off the heating power. Other analysis conditions are the same as in Example 1, but the temperature is programmed to 275° C., and qualitative analysis is performed by GC-MS.

Embodiment 3

[0059] Extraction and enrichment of pesticide residues in yoghurt samples.

[0060] A 1.5mL conical bottom extraction sample bottle was used, and the inner wall was coated with a cross-linked 20mg SE-54 stationary phase with a film thickness of about 14μm. Take 1 mL of yogurt and add it to a 1.5 mL extraction sample bottle, seal it according to the method in Example 1, and then place it on a thermostatic rocker at a constant temperature of 40 ° C for 60 min and a frequency of 10 Hz. The subsequent steps were the same as in Example 2, and were analyzed by GC-MS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com