Laser recticle dedusting plant and dedusting method

A technology of laser engraving and dust removal equipment, applied in laser welding equipment, smoke removal, welding equipment and other directions, can solve the problems of pollution energy consumption, incomplete dust removal, loud noise, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

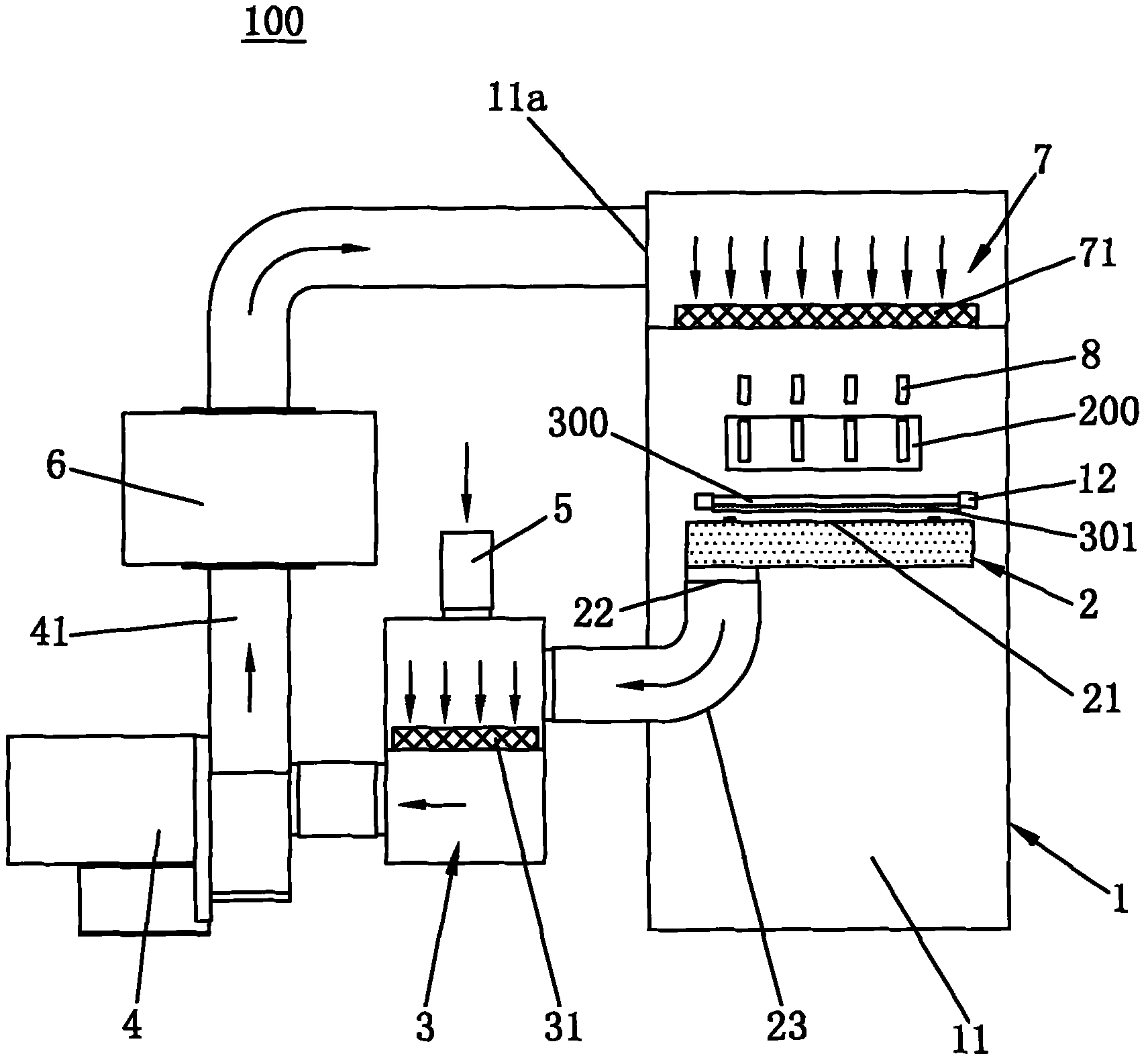

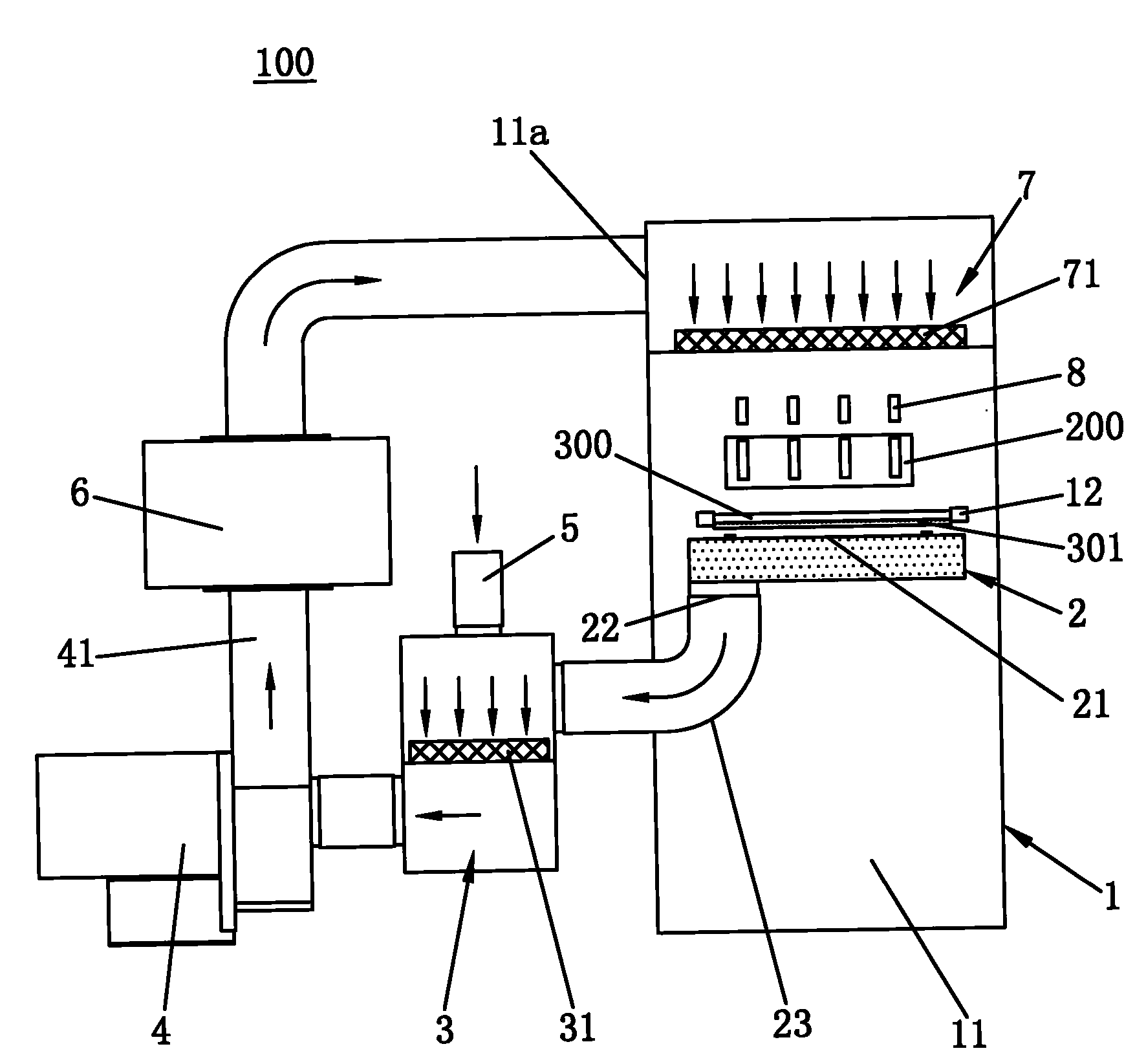

[0017] Such as figure 1 As shown, the laser engraving dust removal equipment 100 of the present invention includes a processing unit 1, a dust suction device 2, a first filter unit 3, a high-pressure exhaust fan 4, an air supply device 5, a constant temperature and humidity unit 6, a second filter unit 7 and Several electrostatic precipitating sticks 8.

[0018] The processing unit 1 includes an inner cavity 11 and a workbench 12, the workbench 12 and the laser generator 200 are placed in the inner cavity 11, and the amorphous silicon solar glass substrate 300 is carried on the workbench 12 The laser generator 200 is placed on the lower surface of the workbench 12 .

[0019] The dust suction device 2 has a dust suction port 21, a dust discharge port 22 and a dust suction pipe 23. The dust suction port 21 is facing the bottom of the workbench 12 and completely covers the amorphous silicon solar glass substrate 300. , the area of the dust suction port 21 is larger than the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com