Vacuum cleaner

a vacuum cleaner and vacuum technology, applied in the field of vacuum cleaners, can solve the problems of not providing much of the pressure drop and achieve the effects of high particle removal, and substantial resistance to the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The filter assembly of the instant invention may be used in conjunction with any vacuum cleaner. For example, the filter assembly may be used for an upright vacuum cleaner, a canister vacuum cleaner or a central vacuum cleaner or the like. The dirty air stream which is processed using the filter assembly described herein may be collected by, for example, a wand or rotating brush positioned in the head of a vacuum cleaner as is known in the art. Such dirty air streams typically comprise dirt of varying particle sizes entrained in an air stream. It will be appreciated that the invention may also be used with a wet / dry vacuum cleaner.

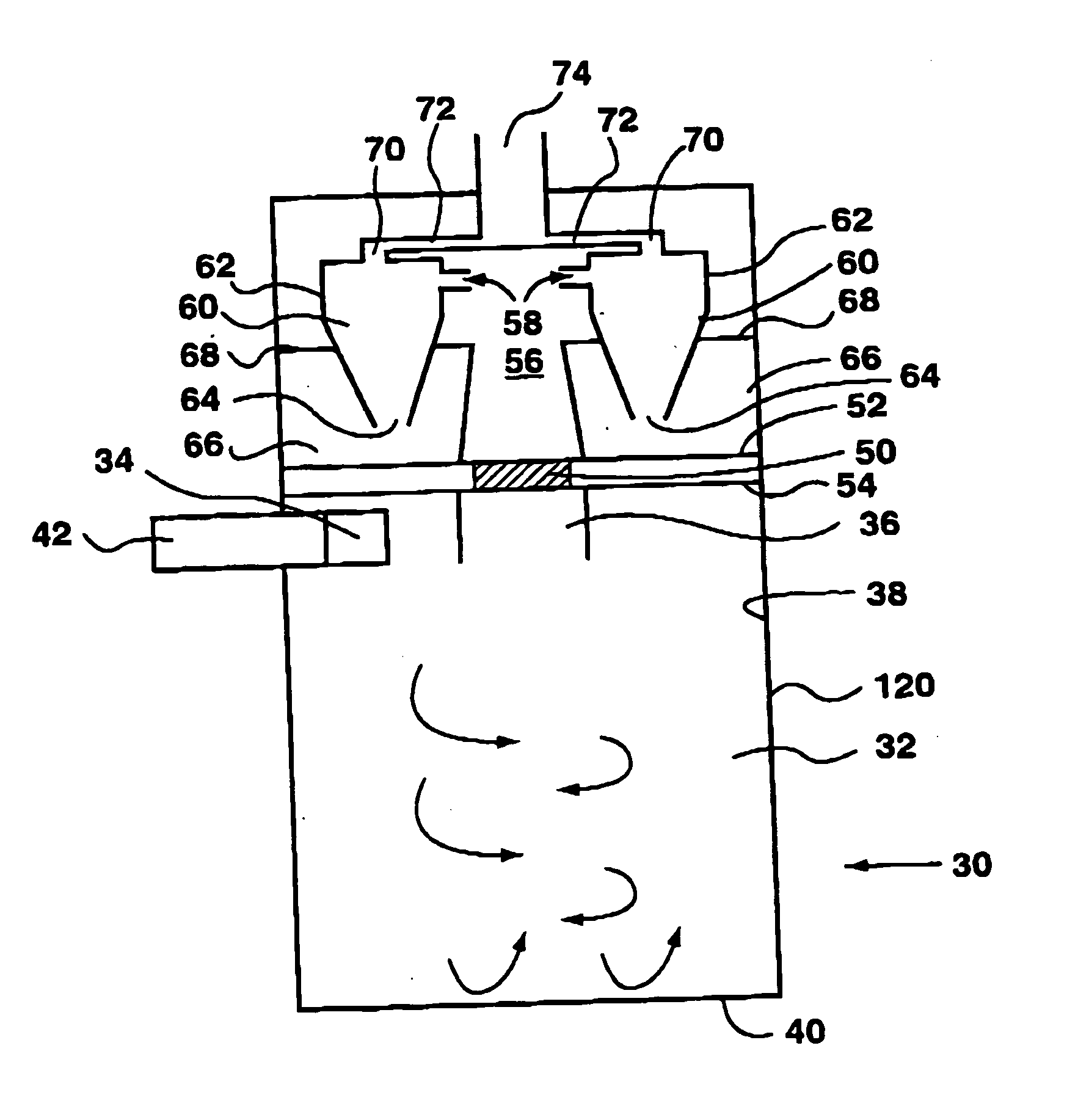

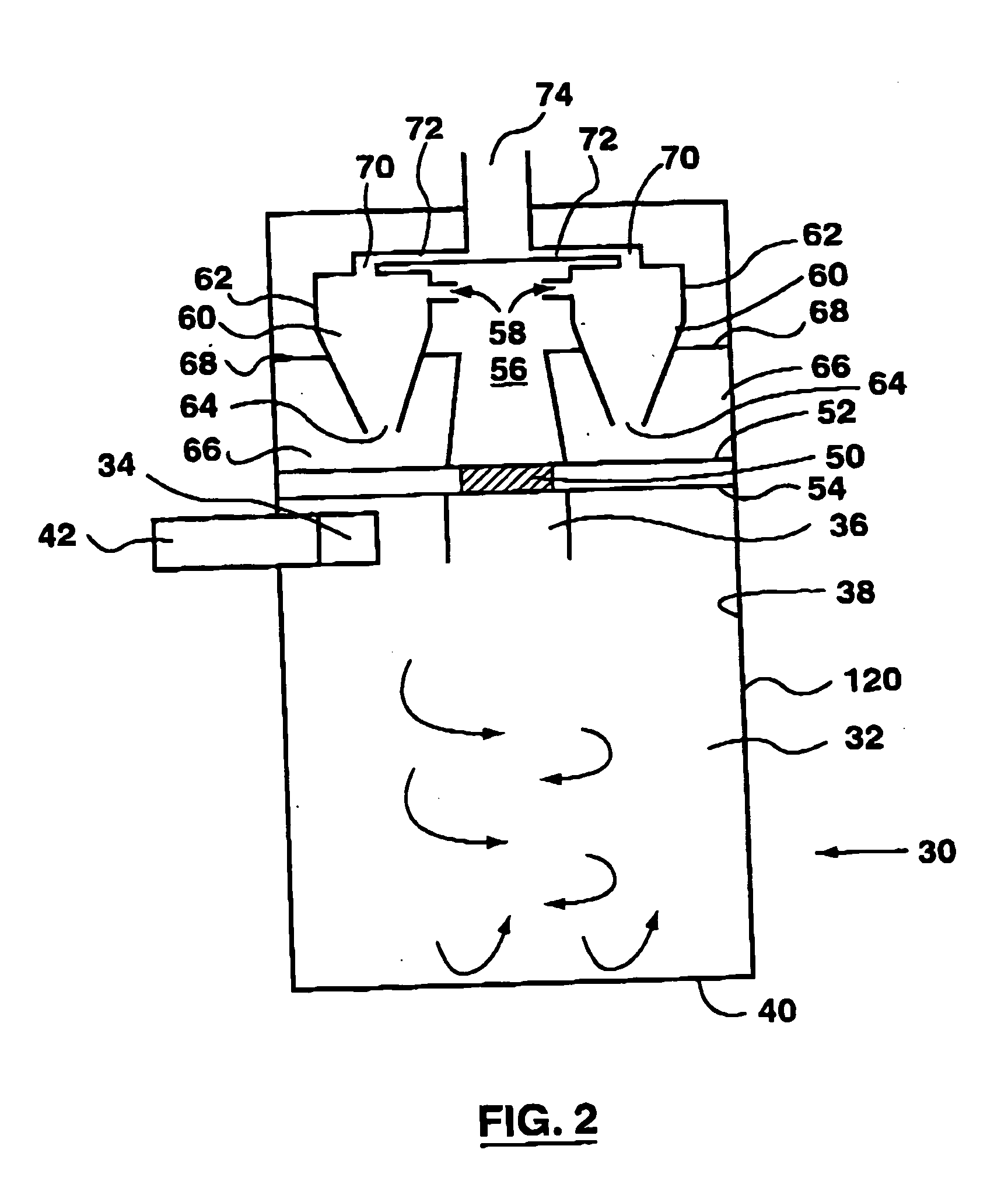

[0072] The filter assembly may be used in conjunction with any design known in the art. For example, as shown in FIGS. 2 and 3, the cyclone may be a cylindrical cyclone having a dirty air feed conduit which is positioned exterior to cyclone bin 120. Alternately, as shown in FIGS. 4 and 5, the cyclone may be a cylindrical cyclone having a dirty air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com