Electrostatic precipitator with high-efficiency dust collecting pole

A technology of electrostatic precipitator and dust collector, which is applied in the direction of electrode structure, electrostatic separation, electrode cleaning, etc. It can solve the problems of fixed area, low efficiency of dust removal, and secondary flying of dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

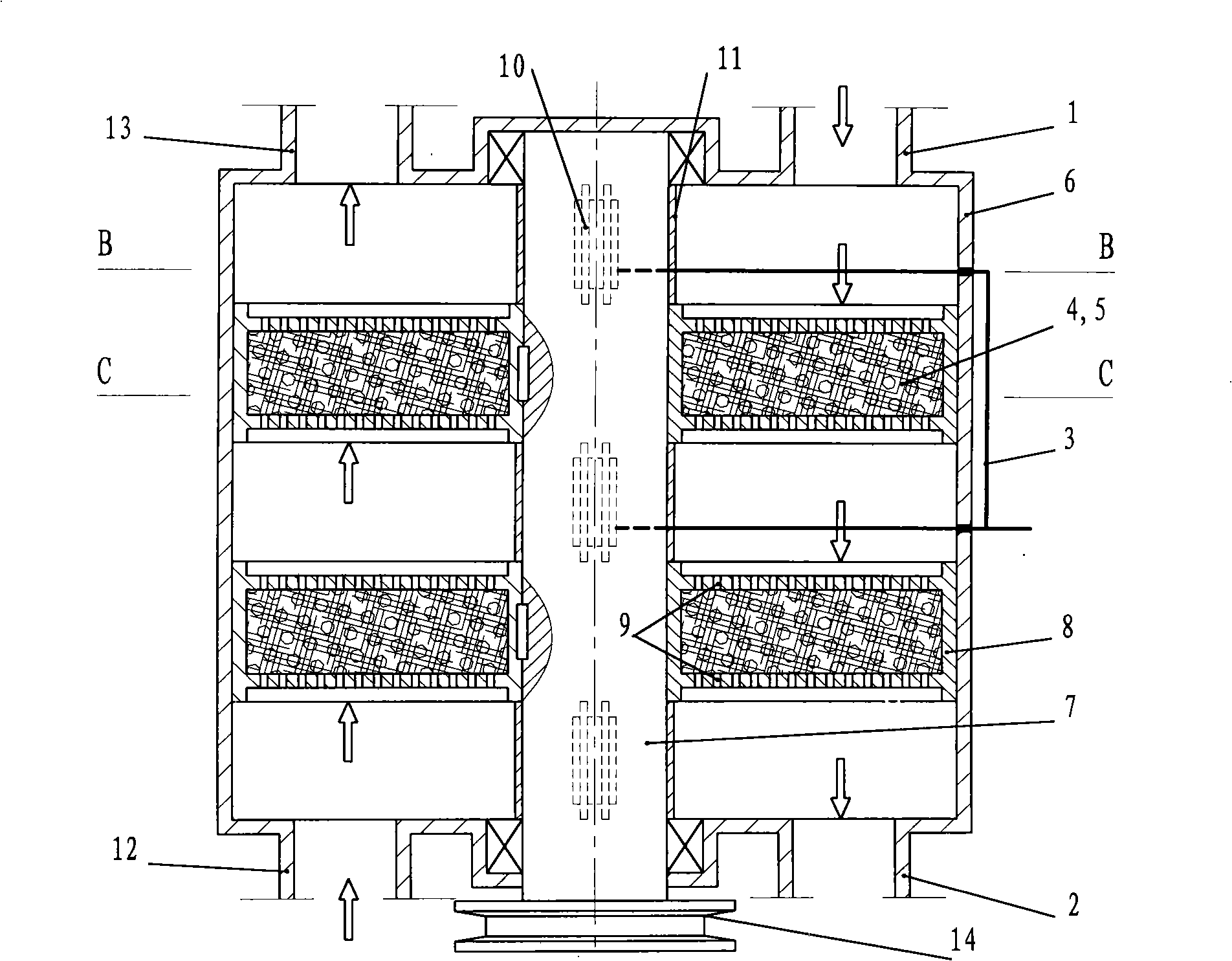

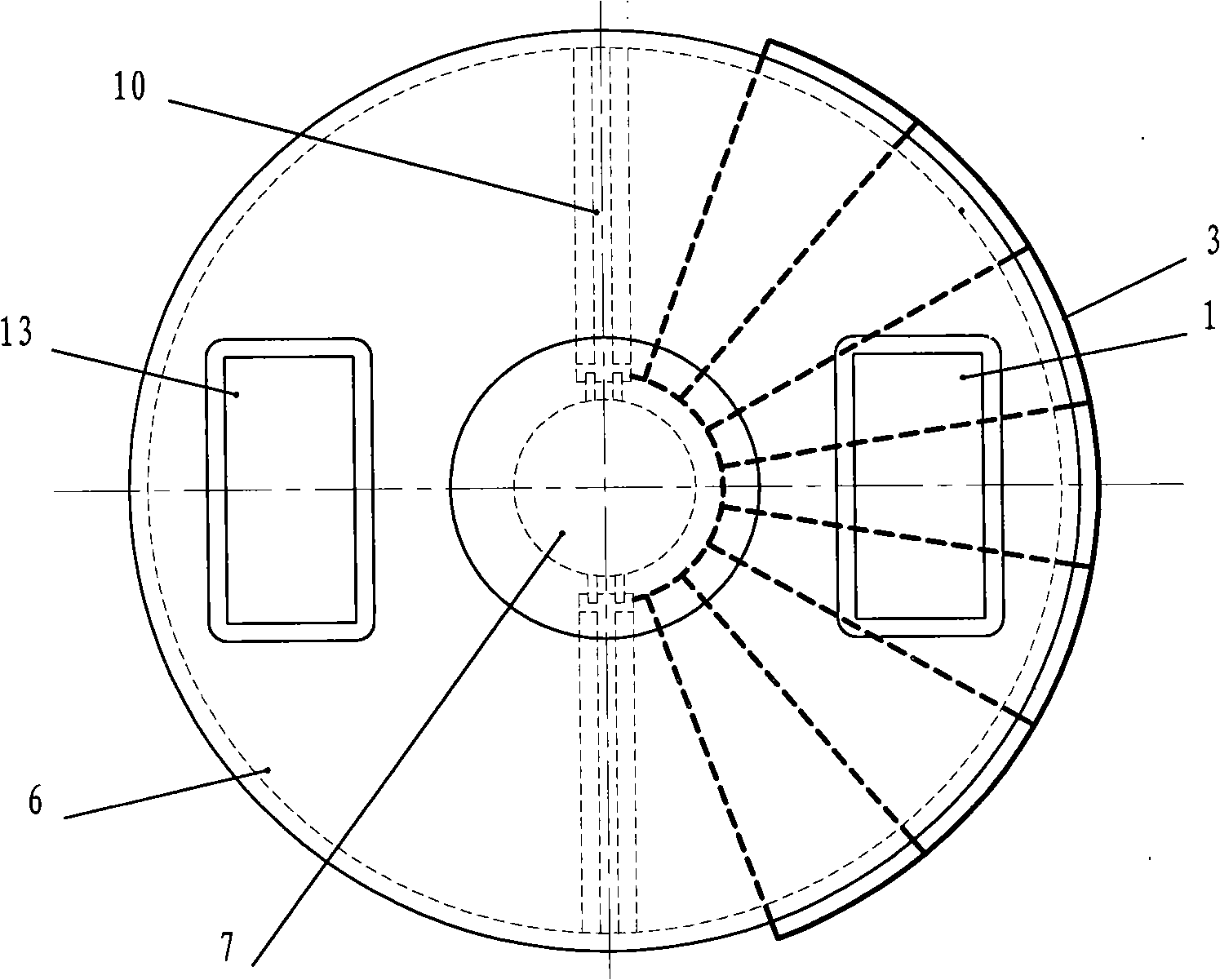

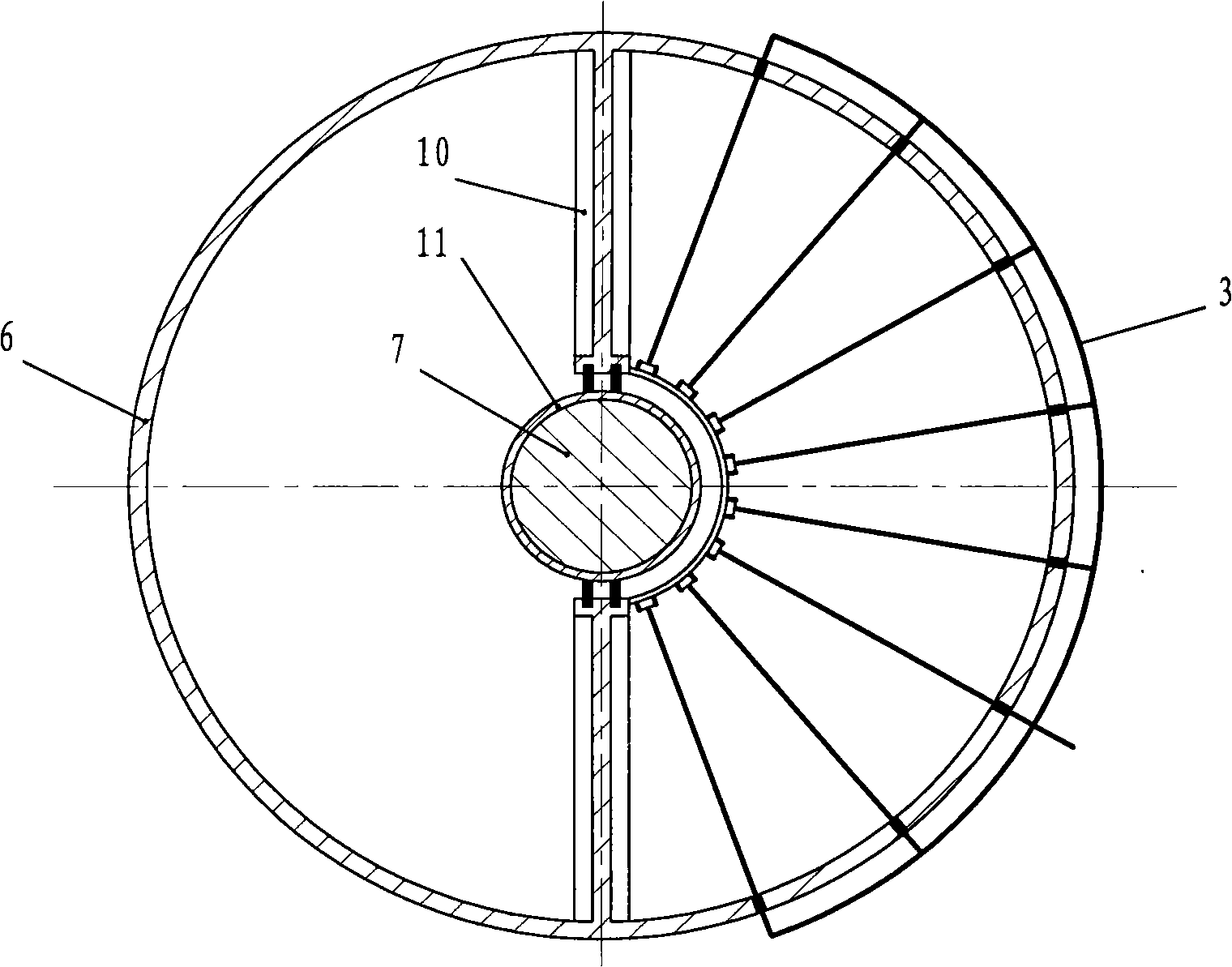

[0019] Depend on figure 1 Visible, the electric precipitator of efficient dust-collecting pole of the present invention comprises the housing that is provided with air inlet and outlet 1,2, discharge electrode 3 and dust-collecting pole are housed in the housing, and wherein dust-collecting pole comprises the hollowed-out metal casing and The shell is filled with a dust collection plate 4 or a dust collection ball 5 made of porous foam metal material or conductively treated porous foam plastic, and the dust collection plate 4 or dust collection ball 5 is placed in the integration room and the dust cleaning room movement between. According to this inventive idea, an electrostatic precipitator with three structures of dust collecting poles, namely rotary type, flat screen rotating curtain type and circulating flow type, has been designed.

[0020] Figure 1 ~ Figure 4 It is a schematic cross-sectional schematic diagram of the principle of an electrostatic precipitator with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com